Aluminum welding wire 5183 5356

Aluminum welding wire 5183 and 5356 are magnesium-based aluminum alloys that are known for their excellent corrosion resistance, particularly in marine and high-strength applications. These welding wires are often used for MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, especially in industries like aerospace, marine, and transportation.

Comparison of 5183 5356 Aluminum Welding Wire

Feature | ER5183 | ER5356 |

Magnesium Content | 4.3-5.3% | 4.5-5.5% |

Wire Diameters | 1.2、1.6、2.0、2.4、3.0、4.0、5.0(mm) | 0.8、1.0、1.2、1.6、2.0、2.4、3.0、3.2、4.0、5.0、6.0(mm) |

Weldability | Good, suitable for MIG and TIG |

Excellent, widely used in MIG and TIG welding |

Welding Applications | Marine, aerospace, pressure vessels, heavy-duty equipment | Marine, aerospace, pressure vessels, high-strength structural applications |

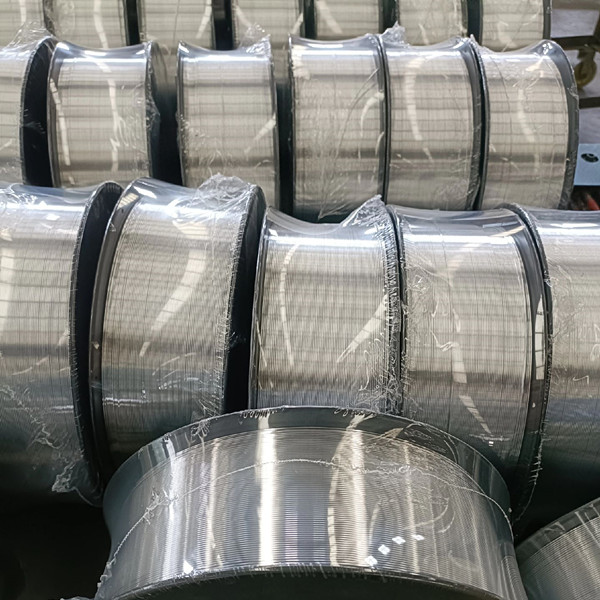

Aluminum welding wire 5183 5356 Wire Reel

D300 (9 kg)

D270 (7 kg)

D200 (2 kg)

D100 (0.5 kg)

Aluminum welding wire 5183 5356 Packaging Types

Spool wire

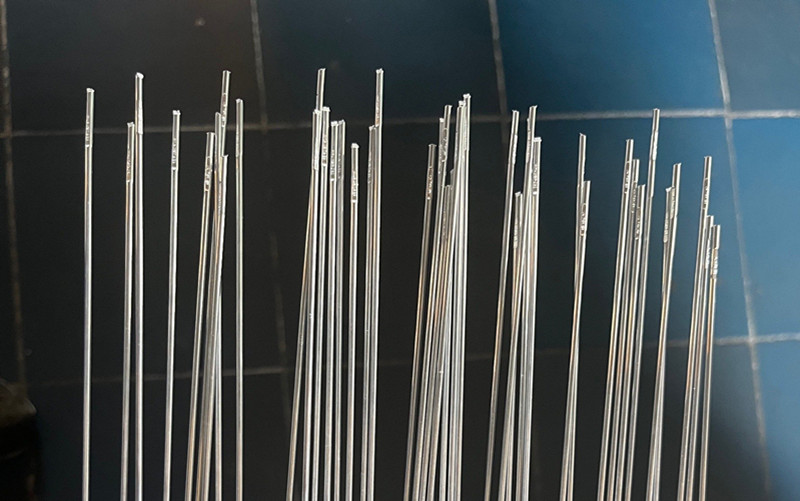

straight bars

coil wire

bucket packaging

Applications of Aluminum welding wire 5183 5356

l Marine Applications: Widely used in shipbuilding, offshore platforms, marine vessels, and marine equipment.

l Pressure Vessels and Tanks: Suitable for high-pressure and high-temperature applications, such as chemical processing equipment and pressure vessels.

l Aerospace: Aircraft components, structural parts, and high-strength applications.

l Welding Aluminum Alloys: 5356 is frequently used to weld 5xxx series aluminum alloys like 5083, 5086, and 5754.

5183 Aluminum Welding Wire is a high-strength alloy commonly used for marine, aerospace, and heavy-duty structural applications. It provides excellent corrosion resistance and weldability, making it ideal for welding marine structures, pressure vessels, and high-stress components. It is also used in aerospace and military applications due to its strength and corrosion resistance.

5356 Aluminum Welding Wire is widely used for applications requiring high strength and fatigue resistance. It is particularly suitable for marine structures, offshore platforms, pressure vessels, and high-strength welding applications. It has better fatigue resistance compared to 5183 and is highly corrosion-resistant in marine environments.