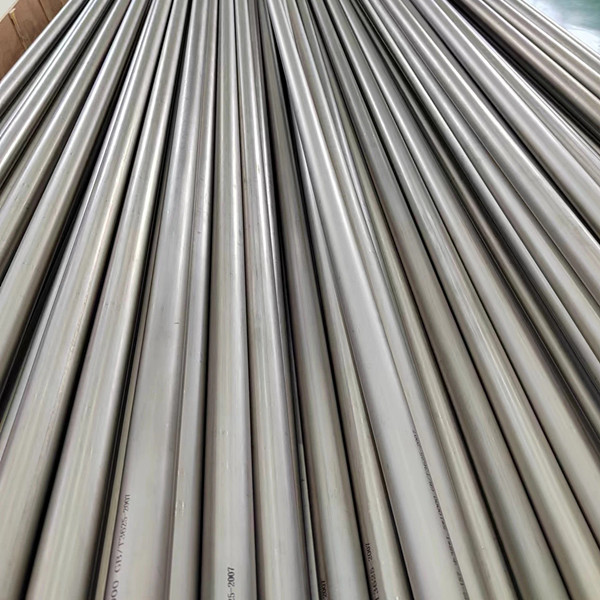

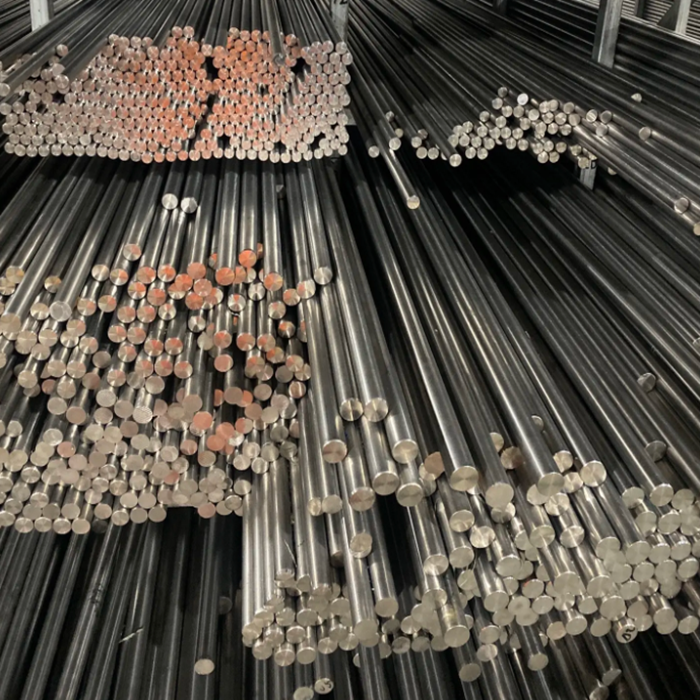

ASTM B348 Titanium CP Grade 1 Round Bar

CP Grade 1 Titanium round bar stands out among the four commercially pure titanium grades for its superior ductility and formability. It also offers exceptional corrosion resistance in oxidizing or moderately reducing environments, including those containing chlorides. With excellent toughness even at low temperatures. CP Grade 1 Titanium round bar is highly versatile, allowing for easy welding, machining, and deformation in both hot and cold conditions

Size for CP Grade 1 Titanium round bar

CP Grade 1 Titanium round bar | Size |

Diameter | 0.4mm – 300mm ( larger) |

Length | 100mm --6000mm (custom lengths available) |

Chemical Composition of CP Grade 1 Titanium round bar

Element | Maximum Content (%) |

Titanium (Ti) | ~99.5 (minimum) |

Oxygen (O) | 0.18 |

Nitrogen (N) | 0.03 |

Carbon (C) | 0.08 |

Hydrogen (H) | 0.015 |

Iron (Fe) | 0.2 |

Standards of CP Grade 1 Titanium round bar

Standard | Focus Area | Application |

ASTM B348 | Chemical and mechanical properties of titanium bars. | General-purpose applications in aerospace, medical, and chemical processing. |

ASME SB348 | Titanium bars for pressure vessels and piping systems. | Industrial and structural applications in pressure systems. |

AMS 4921 | High-performance titanium alloy bars (e.g., 6Al-4V). | Aerospace and high-stress structural components. |

Mechanical Properties of CP Grade 1 Titanium round bar

Property | Value |

Tensile Strength | 240 MPa (minimum) |

Yield Strength | 170 MPa (minimum) |

Elongation | 24% (minimum) |

Density | 4.51 g/cm³ |

Hardness | 70-100HB |

Why Choose CP Grade 1 Titanium round bar?

1. Lightweight yet strong for weight-sensitive applications.

2. Resistant to a wide range of chemical and environmental exposures.

3. Excellent thermal and electrical conductivity compared to other metals.

4. Sustainable and recyclable material.

Typical Applications of CP Grade 1 Titanium round bar

Chemical Processing: Used in heat exchangers, tanks, and piping systems due to its resistance to corrosive chemicals.

Aerospace: Ideal for lightweight structural components exposed to varying environments.

Marine Industry: Excellent performance in seawater applications like shafts, fittings, and fasteners.

Medical Devices: Widely used for implants and surgical instruments due to its biocompatibility.

Energy Sector: Used in desalination plants, power plants, and other equipment exposed to corrosive conditions.