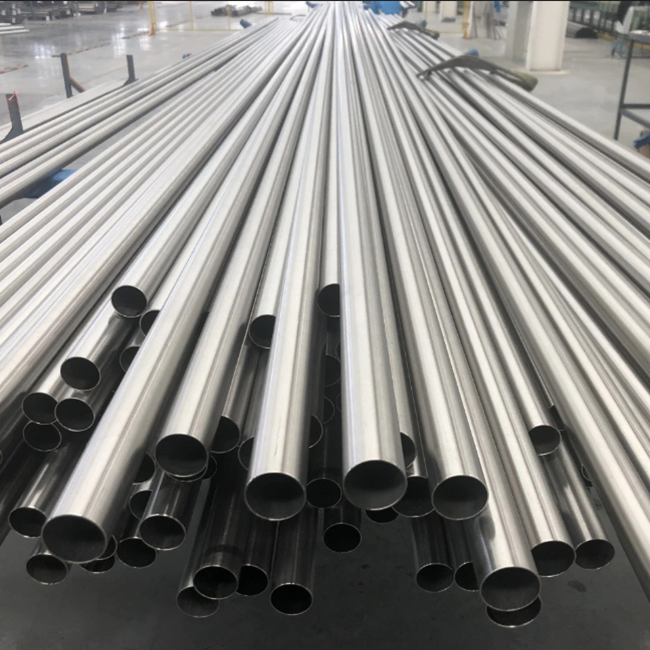

Large-diameter High-precision Seamless Titanium Tubes for Marine Aerospace

Large-diameter high-precision seamless titanium tubes refer to titanium tubing with an outer diameter typically above 300mm, featuring high dimensional accuracy and no welding seams. These titanium tubes are formed through integrated processes such as extrusion, piercing, and hot rolling, resulting in superior strength and excellent pressure resistance. They are widely used in applications that demand high strength, corrosion resistance, and structural integrity, including hydraulic systems and high-pressure pipelines in aerospace, seawater desalination and subsea pipelines in marine engineering, corrosion-resistant heat exchangers and pressure vessels in the petrochemical industry, as well as large structural components in medical equipment.

Titanium Tube Stock Size

| Large Diameter Titanium Tubes | Size |

Ti-6Al-4V, Ti-6Al-7Nb, Ti-5Al-2.5Fe, Grade 5, Grade 1, Grade 2 | Φ325*12、 Φ325*10 Φ325*6、 Φ270*25 Φ273*10、 Φ219*10 Φ219*9、 Φ219*8 Φ219*6、 Φ219*4 Φ194*6、 Φ190*11 Φ180*11、 Φ180*9 Φ168*7、 Φ168*6 Φ168*4、 Φ159*8 Φ159*6、 Φ159*5 Φ159*4、 Φ159*4.5 Φ159*3、 Φ159*17.5 Φ154*6、 Φ152*13.5 Φ152*3、 Φ141*6.35 Φ140*3、 Φ135*5.5 Φ135*5、 Φ133*4.7 Φ133*5、 Φ133*4 Φ133*3、 Φ127*8 Φ114*4、 Φ114*3 Φ108*4、 Φ108*3 Φ102*2、 Φ89*3 |

| Length | 100mm --6000mm (custom lengths available) |

Titanium cutting services

We not only supply large-diameter high-precision seamless titanium tubes, but also offer professional cutting services. When cutting titanium tubing, we fully understand the material’s low thermal conductivity and high chemical reactivity, which can cause tool sticking or wear during machining. Therefore, we use specialized cutting tools and techniques designed for titanium alloys to ensure a precise and stable cutting process.

After cutting, we perform deburring on the tube ends and, depending on the customer’s application, we can also carry out acid pickling or mechanical cleaning to remove the oxidation layer. This ensures that the cut surface is clean and suitable for welding or further processing.

For applications with extremely high precision requirements—such as medical devices or aerospace components—we leave an appropriate machining allowance, allowing our clients to perform final finishing and tolerance adjustments as needed.