BS L168-T6511 Aircraft Aluminium Alloy 2014A T6511 Flat Rectangular Bars

Aluminium Alloy BS L168 T6511 is a British aerospace standard that specifies requirements for high-strength aluminum alloy flat and rectangular bars, typically used in the aerospace industry.

Aluminium Alloy L168 is a high strength 4-5% Copper alloy with very good machinability.It is typically used in Aerospace and Defence Components also in High Technology Applications.

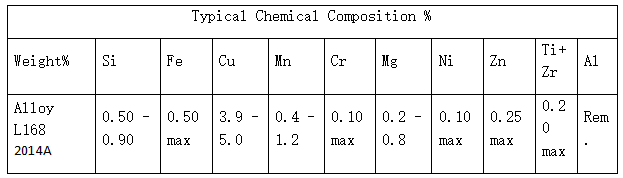

Chemical Composition of Aircraft Aluminium Alloy 2014A T6511 Flat Rectangular Bars

Typical Sizes

Dimension | Range |

Thickness | 6 mm --300 mm |

Width | 20 mm --600 mm |

Length | 3000 mm -- 6000 mm (custom lengths available) |

Generic Physical Properties

Physical Property | Value |

Density | 2.80 g/cm³ |

Melting Point | 640 °C |

Thermal Expansion | 22.8 x10^-6 /K |

Modulus of Elasticity | 73 GPa |

Thermal Conductivity | 155 W/m.K |

Electrical Resistivity | 40 % IACS |

Mechanical Properties of Aircraft Aluminium Alloy 2014A T6511 Flat Rectangular Bars

Thickness | Proof Strength (Min) | Tensile Strenth (Min) | Elongation % (Min) |

6mm-63.5mm | 370 | 415 | 6 |

63.5mm-254mm | 385 | 435 | 6 |

Applications

Aircraft Structures: Wing spars, fuselage components, and landing gear parts.

Automotive Industry: High-performance components requiring strength and corrosion resistance.

Marine Applications: Lightweight and corrosion-resistant fittings.

Industrial Machinery: Precision parts in robotics and manufacturing equipment.