Aerospace aluminum 2024 T351 T3 T4 sheet Plate

The 2024 T351 T3 T4 aluminum sheet is commonly used in the aerospace industry. 2024 aluminum is a alloy with copper as the primary alloying element, featured with high strength, excellent fatigue performance, low density, good machinability, and appropriate heat treatment capabilities. So these advantages could explain why so widely be used in aircraft structures and components.

2024 aluminum properties (T3, T4, T351)

| Property | 2024-T3 | 2024-T4 | 2024-T351 |

|---|---|---|---|

| Temper Condition | Cold worked + naturally aged | Solution treated + naturally aged | Solution treated + stress-relieved by stretching |

| Tensile Strength (MPa) | ≥ 470 | ≥ 470 | ≥ 470 |

| Yield Strength (MPa) | ≥ 325 | ≥ 325 | ≥ 330 |

| Elongation (%) | ≥ 10 (50mm gauge length) | ≥ 12 (50mm gauge length) | ≥ 8 (50mm gauge length) |

| Residual Stress | High (from cold working) | Low | Very low (removed by stretching) |

| Typical Applications | Aircraft skin, wing ribs | Sheet metal forming parts | Spars, precision frames |

| Corrosion Resistance | Poor (requires cladding/coating) | Poor (requires cladding/coating) | Poor (requires cladding/coating) |

| Workability | Moderate (avoid secondary cold work) | Good (suitable for bending) | Moderate (avoid high-stress machining) |

| Density (g/cm³) | 2.78 | 2.78 | 2.78 |

Key Differences

T3: Cold worked for higher strength but with significant residual stress.

T4: Naturally aged for better formability, ideal for complex sheet metal parts.

T351: Offers best dimensional stability for load-bearing structures.

(Data sources: ASTM B209, AMS 4037)

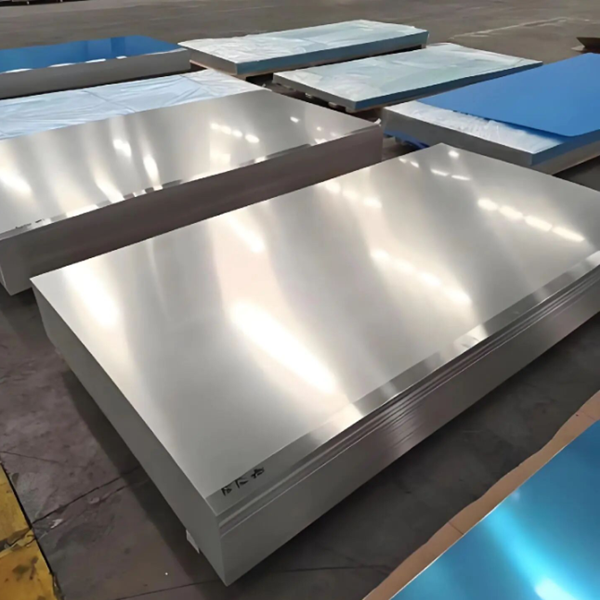

2024 Aluminum Plate Specifications

| Alloy | Temper | Thickness (mm) | Width (mm) × Length (mm) |

|---|---|---|---|

| 2024 | T351, T4, T3 | Thin (≤10mm): 0.5, 0.6, 0.8, 1, 1.2, 1.5, 2.5, 3.5, 4, 5, 8 Medium (10–50mm): 12, 14, 15, 16, 18, 20, 22, 25, 28, 30, 35, 40, 45, 50 Thick (50–100mm): 55, 60, 65, 70, 75, 80, 90, 95, 100 Extra Thick (>100mm): 110, 120, 130, 140, 170, 180, 230 | 1500×3000, 1000×2000, 2000×4000, 1250×2500 |

Aluminum alloy 2024 applications:

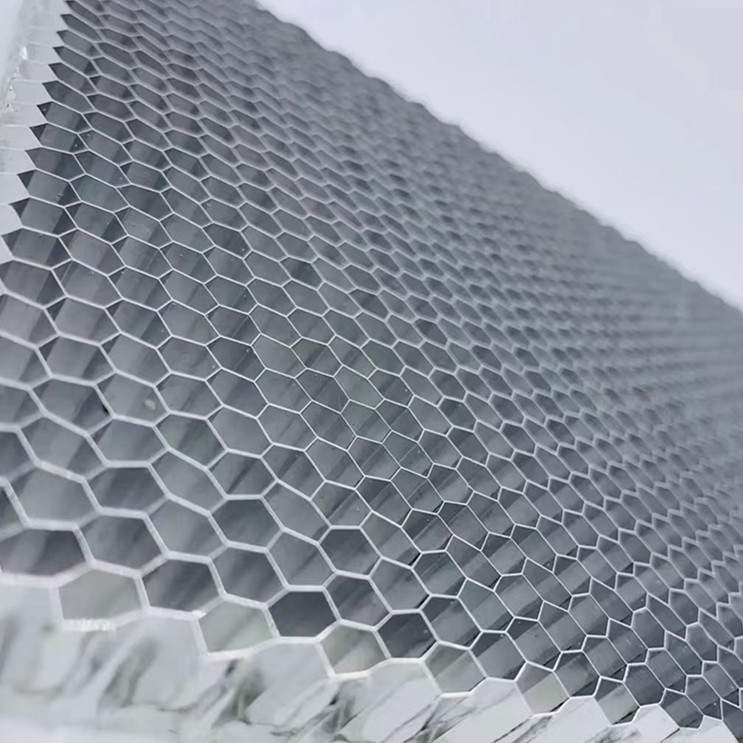

1. Aircraft Wings and Fuselage Structures

2. Trusses and Beams

3. Fasteners and Connectors

4. Landing Gear and Support Structures

5. Engine Mounts and Attachments

6. Missile and Spacecraft Structures

7. Internal Fittings and Seat Frames

8. Mounts for Electronic Equipment and Instruments