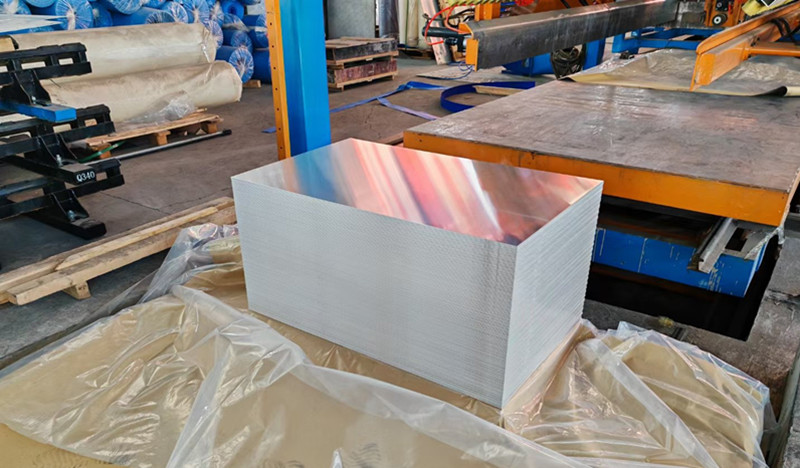

Aluminum Alloy 4343 3003 Brazing weld Sheet and Coil

Aluminum 4343/3003 brazing sheet is a clad aluminum material used for heat exchangers and other brazing applications. It consists of a 4343 clad layer (6%-15%) over a 3003 core, combining excellent corrosion resistance, thermal conductivity, and brazing performance.

This composition ensures high brazing performance, corrosion resistance, and thermal conductivity, making it ideal for automotive, HVAC, and industrial heat exchanger applications.

Chemical Composition of Alloy 4343/3003 Aluminum Brazing Sheet & Coil

Element | 4343 (Cladding Layer 6%-15% ) wt.% | 3003 (Core Material) wt.% |

Si | 6.8 – 8.2 | ≤ 0.6 |

Fe | ≤ 0.8 | ≤ 0.7 |

Cu | ≤ 0.3 | 0.05 – 0.20 |

Mn | ≤ 0.10 | 1.0 – 1.5 |

Mg | — | ≤ 0.3 |

Zn | ≤ 0.2 | ≤ 0.1 |

Ti | ≤ 0.15 | ≤ 0.1 |

Al | Balance | Balance |

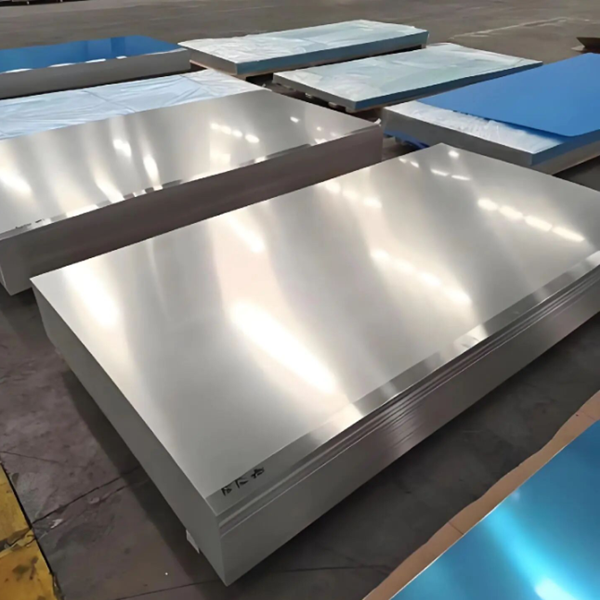

Size of Alloy 4343/3003 Aluminum Brazing Sheet & Coil

Form | Thickness (mm) | Width (mm) | Length |

Coil | 0.2 – 3.0 | 10 – 1600 | Continuous coil |

Sheet | 0.2 – 3.0 | 100 – 1600 | Custom-cut as per request |

Key Features of Alloy 4343/3003 Aluminum Brazing Sheet & Coil

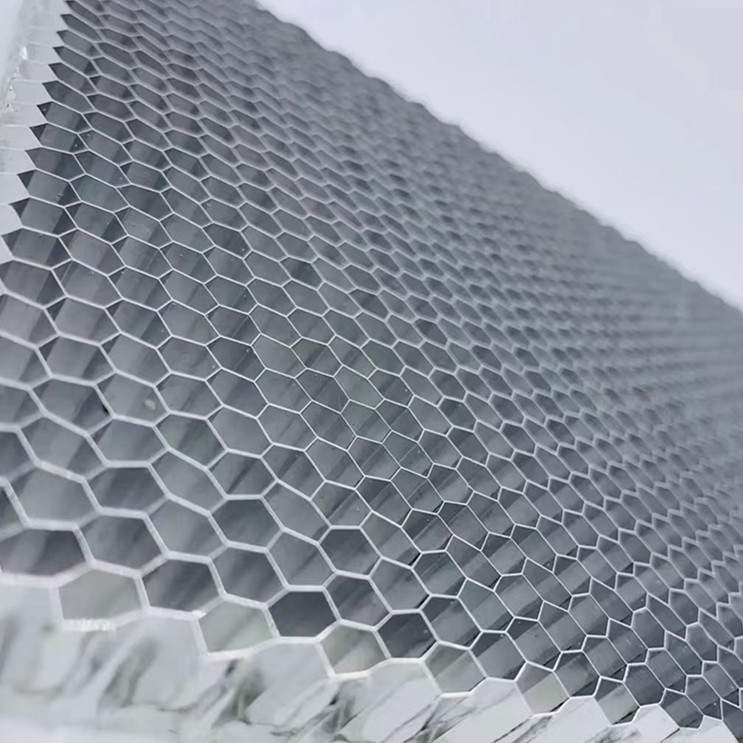

1.Excellent Brazing Performance: The 4343 clad layer provides superior filler metal properties, ensuring smooth and strong brazed joints.

2.Good Corrosion Resistance: The 3003 core enhances durability in humid or aggressive environments.

3.High Thermal Conductivity: Ideal for heat dissipation in heat exchangers.

4.Formability & Workability: Easily formed into complex shapes for radiators, condensers, and evaporators.

5.Lightweight & Durable: Suitable for automotive, HVAC, and industrial applications.

Application of Alloy 4343/3003 Aluminum Brazing Sheet & Coil

Automotive Industry

· Radiators

· Oil coolers

· Intercoolers

· Condensers & evaporators

HVAC & Refrigeration

· Air conditioning systems

· Heat exchanger fins & tubes

Industrial Applications

· Power plant cooling systems

· Electronic cooling modules