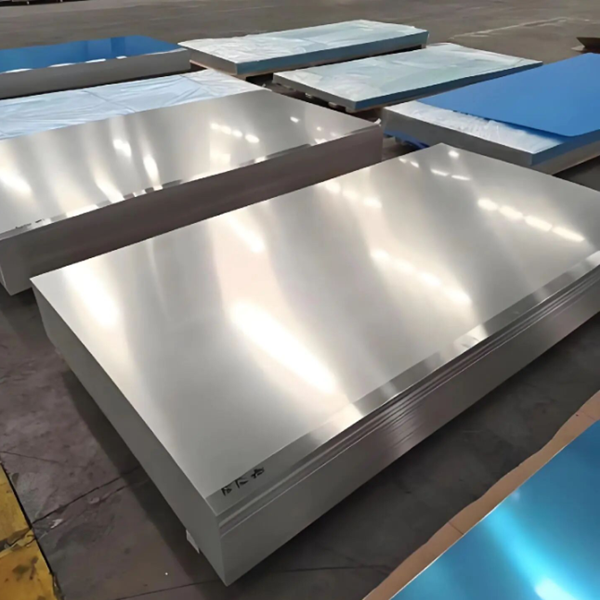

Aluminum Plate Sheet Alloys 5082 | 5754 | 5182 | 5083 | 5052

Aluminum Plate Sheet Alloys 5082/5754/5182/5083/5052,these alloys belong to the 5xxx series, which are aluminum-magnesium alloys known for their excellent corrosion resistance and high strength-to-weight ratio..

Comparative Summary of Aluminum Plate Sheet Alloys 5082/5754/5182/5083/5052

Alloy | Magnesium (%) | Strength | Common Applications |

5082 | 4.0-4.2 | Medium-High | Marine, Offshore, Pressure Vessels |

5754 | 2.6-3.0 | Medium | Marine, Trucks, Automotive |

5182 | 4 | High | Automotive (Fuel Tanks), Marine |

5083 | 4.0-4.9 | High | Marine, Shipbuilding, Military |

5052 | 2.2-2.5 | Medium | Marine, Automotive, Chemical Processing |

Size of Aluminum Plate Sheet Alloys 5082/5754/5182/5083/5052

Alloy | 5082 | 5754 | 5182 | 5083 | 5052 |

Thickness | 0.5 mm- 150 mm | 0.5 mm- 150 mm | 0.5 mm- 150 mm | 0.5 mm- 150 mm | 0.5 mm- 50 mm |

Width | 100mm-2400 mm | 100mm-2400 mm | 100mm-2400 mm | 100mm-2400 mm | 100mm-2000 mm |

Length | 1000mm-8000mm | 1000mm-8000mm | 1000mm-8000mm | 1000mm-8000mm | 1000mm-6000mm |

Surface Finish | Mill Finish, Anodized, checkered | Mill Finish, Anodized, checkered | Mill Finish, Anodized, checkered | Mill Finish, Anodized, checkered | Mill Finish, Anodized, checkered |

Heat Treatment | O,H111,H112, H116,H118,H26 | O,H111,H112 ,H116,H118,H26 | O,H111,H112 ,H116,H118,H26 | O,H111,H112 ,H116,H321 | O,H32 |

5082, 5754, 5182, 5083, and 5052 are all part of the 5xxx series of aluminum alloys, offering a balance of strength, corrosion resistance, and weldability.

These alloys are particularly suited for applications where corrosion resistance is critical, such as in marine environments, automotive, aerospace, and chemical processing industries.

The alloys vary in strength and magnesium content, with 5083 and 5182 being stronger options, while 5052 and 5754 are known for their good formability and corrosion resistance.

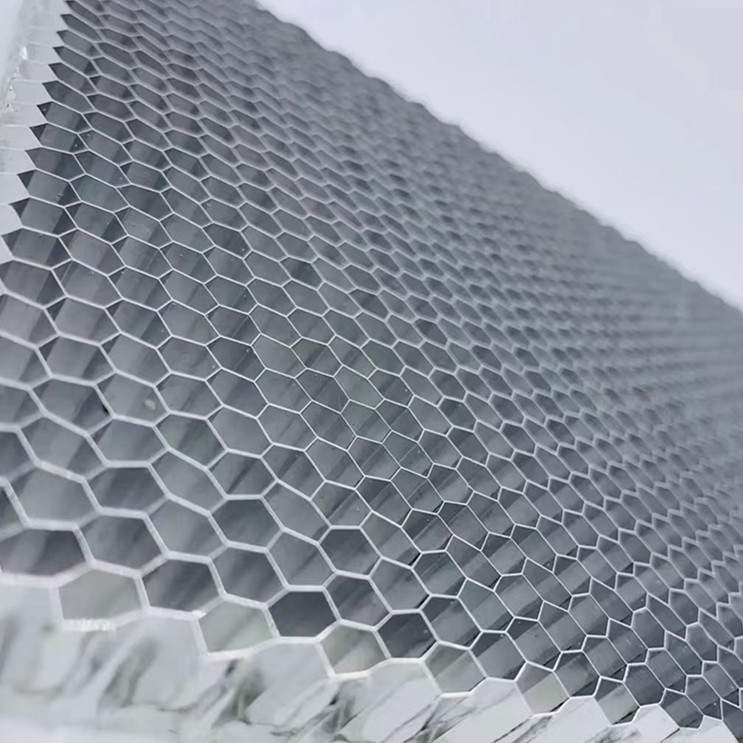

Applications of Aluminum Plate Sheet Alloys 5082/5754/5182/5083/5052

1,Typically used in marine, shipbuilding, offshore, and chemical industries.

2, Commonly used for pressure vessels, storage tanks, and heat exchangers.

3,Often used for high-strength applications where corrosion resistance is critical.