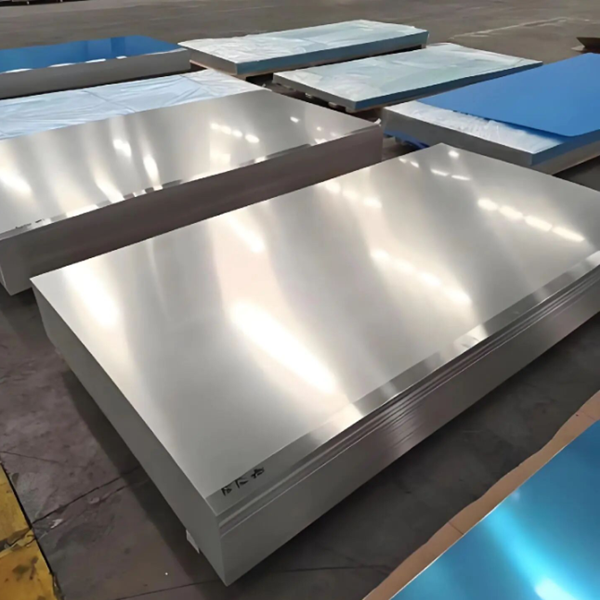

AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

The ASNA3050 aluminum aircraft plate specification corresponds to a 7175-T7351 alloy. It is produced from 6mm thickness up to 100mm thickness This aluminum alloy is designed for aerospace applications requiring high strength, excellent toughness, and resistance to stress corrosion cracking.

Chemical Composition for AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

Element | Content (%) |

Aluminum (Al) | Balance |

Zinc (Zn) | 5.7 - 6.7 |

Magnesium (Mg) | 2.0 - 2.6 |

Copper (Cu) | 1.2 - 2.0 |

Chromium (Cr) | 0.18 - 0.28 |

Iron (Fe) | ≤ 0.15 |

Silicon (Si) | ≤ 0.12 |

Titanium (Ti) | ≤ 0.06 |

Other (each) | ≤ 0.05 |

Other (total) | ≤ 0.15 |

Mechanical Properties for AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

Property | Typical Value |

Tensile Strength | ~510 MPa (74 ksi) |

Yield Strength | ~440 MPa (64 ksi) |

Elongation | ~9-12% |

Dimension of AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

Dimension

| |

Thickness | 6 mm --150 mm |

Width | 100-- 3000 mm |

Length | 100-- 6000 mm (custom lengths available) |

Key Properties of AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

High Strength: Superior tensile and yield strength, making it ideal for structural components.

Corrosion Resistance: Enhanced resistance to stress corrosion cracking due to T7351 temper.

Toughness: Excellent fracture toughness for demanding aerospace applications.

Machinability: Good, particularly in the T7351 temper.

Applications of AMS 4201 ASNA3050 Aluminum aircraft plate 7175 T7351

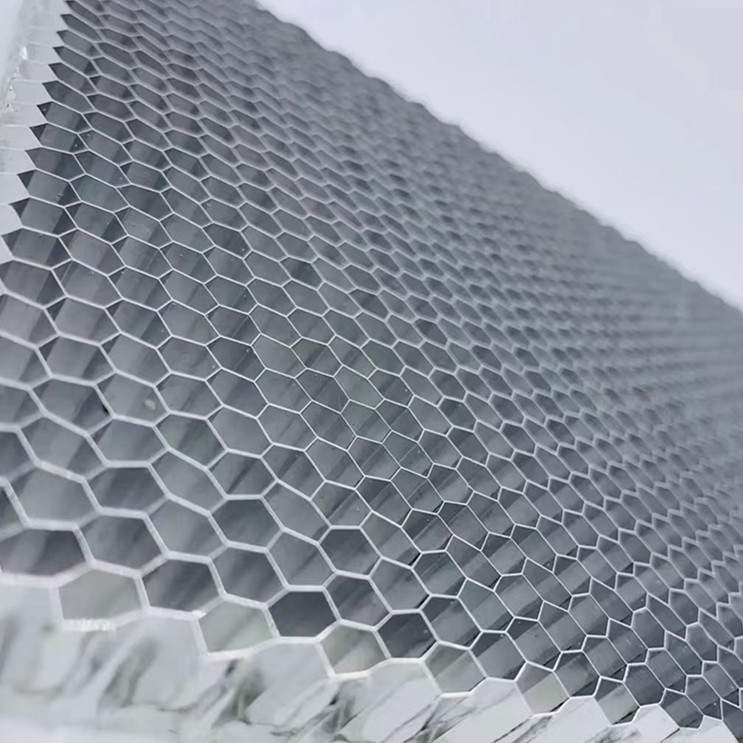

Aerospace Structural Components:

Wing spars

Fuselage frames

Landing gear assemblies

Defense:

Armored vehicle components

High-performance machinery