Anodizing Aluminum Coil Sheet Alloy 5052 5182 5252G 6061G 6063G

5052, 5182, 5252G, 6061G, and 6063G alloys are all suitable for anodizing. Anodizing is an electrochemical process that forms a durable oxide layer on the surface of aluminum alloys, significantly enhancing their corrosion resistance, hardness, and wear resistance, while also improving their appearance by adding various colors and increasing decorative effects. 5052 and 6063G are ideal for applications requiring a high-quality surface and corrosion resistance; 6061G offers good strength and is commonly used for structural components; 5252G is suitable for decorative anodizing; while 5182 has a more general anodizing effect and is suitable for general purposes.

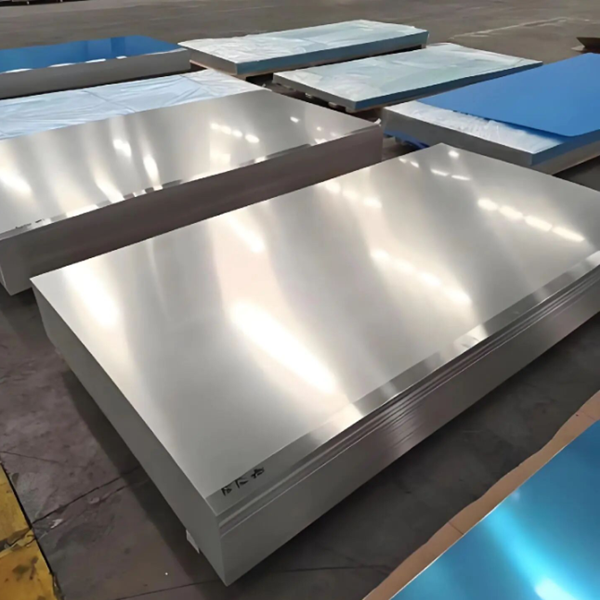

Size of 5052, 5182, 5252G, 6061G Aluminum Coil/Sheet

Products | Thickness(mm) | Width(mm) | Length(mm) |

Aluminum Hot rolled | 2.0mm--12mm | 1050mm--2900mm | coil |

Aluminum Cold rolled | 0.1mm--5.0mm | 1000mm--2650mm | coil |

Aluminum Sheet | 0.2mm--6.0mm | 1000mm--2800mm | 1000mm--12000mm |

5252G (H32/H34/H36)

Application: Suitable for anodizing, offering good corrosion resistance and a fine finish after anodization. The anodized surface of 5252G aluminum alloy results in an even, smooth layer, making it ideal for architectural applications and marine environments, where it demonstrates excellent corrosion resistance.

Properties: Good formability, weldability, and moderate strength.

Common Uses: Primarily used in architectural applications, marine equipment, and transportation where both aesthetic and corrosion resistance are crucial.

6061G (T4/T6/T651)

Application: 6061G aluminum alloy is one of the most popular alloys for anodizing, offering excellent corrosion resistance and superb machinability. After anodizing, it forms a durable oxide film that enhances its longevity, making it suitable for high-strength structural components.

Properties: High strength, good workability, and excellent anodizing response. 6061G aluminum alloy anodizing significantly improves its corrosion resistance and hardness.

Common Uses: Widely used in aerospace, automotive industries, and structural components, especially in aerospace anodized aluminum alloys and automotive parts anodized aluminum alloys.

6063G (T4/T6)

Application: Ideal for anodizing, providing excellent strength and good surface finish. 6063G aluminum alloy anodizing results in a smooth, uniform oxide film, making it an excellent choice for architectural and decorative applications.

Properties: Medium strength, good corrosion resistance, and a high-quality surface finish after anodization. The anodized effect of 6063G aluminum alloy enhances its appearance, making it a preferred choice for decorative uses.

Common Uses: Mainly used in the building industry, window frames, and extrusion profiles, especially in 6063G aluminum alloy architectural applications, where it is widely used in building facades and window frames.

5052 (H32/H34/H36)

Application: Highly suitable for anodizing, providing excellent corrosion resistance, especially in marine environments, where it effectively resists salt spray corrosion. After anodizing, 5052 aluminum alloy anodizing performs exceptionally well in salt fog resistance.

Properties: Highly resistant to corrosion, particularly in marine environments, but slightly less rigid compared to other alloys.

Common Uses: Widely used in marine applications, fuel tanks, and pressure vessels, especially in corrosive environments like ships and marine engineering equipment.

5182 (H14/H24)

Application: 5182 aluminum alloy anodizes well, offering good strength and moderate corrosion resistance, making it suitable for lighter structures and industrial uses.

Properties: Good strength and formability, but slightly less corrosion-resistant than alloys like 5052 or 6061.

Common Uses: Primarily used in automotive industries and general industrial applications, especially for automotive body panels and architectural applications of lighter components, ideal for automotive parts anodized aluminum alloys.