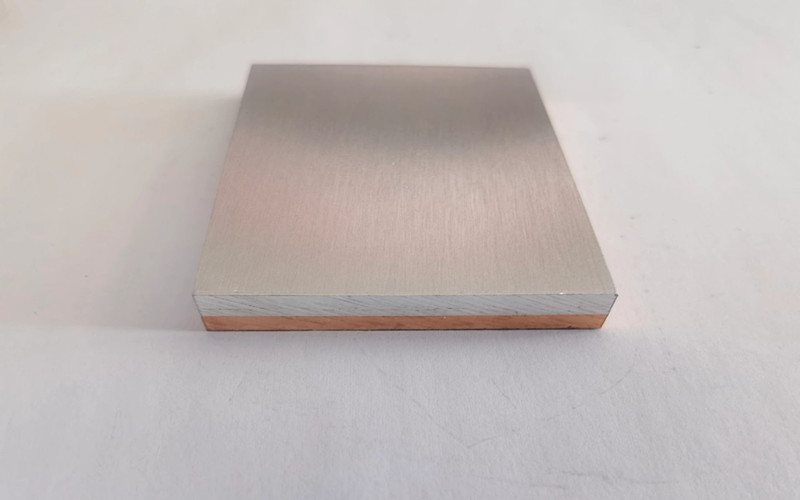

Cupal Metal Sheet Cu-Al Bimetallic

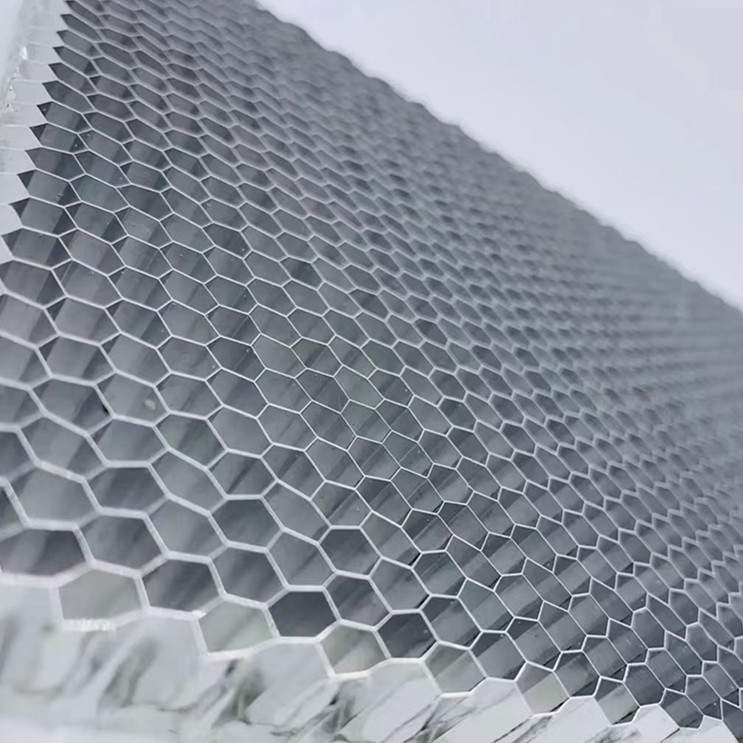

Cu-Al bimetallic sheets, also known as Cupal sheets, are composite materials made by bonding copper (Cu) and aluminum (Al) through high-strength, oxygen-free diffusion welding. This material combines the excellent electrical conductivity of copper with the lightweight and corrosion resistance of aluminum. It is widely used in power, electrical, energy, and electronics industries.

When copper and aluminum are directly connected, especially in humid or electrically active environments, electrochemical corrosion often occurs. This can lead to increased resistance, connection failure, and equipment malfunction. Cu-Al bimetallic sheets serve as an effective intermediate layer, preventing galvanic corrosion and ensuring long-term stable connections. They are a reliable solution to copper-aluminum connection challenges.

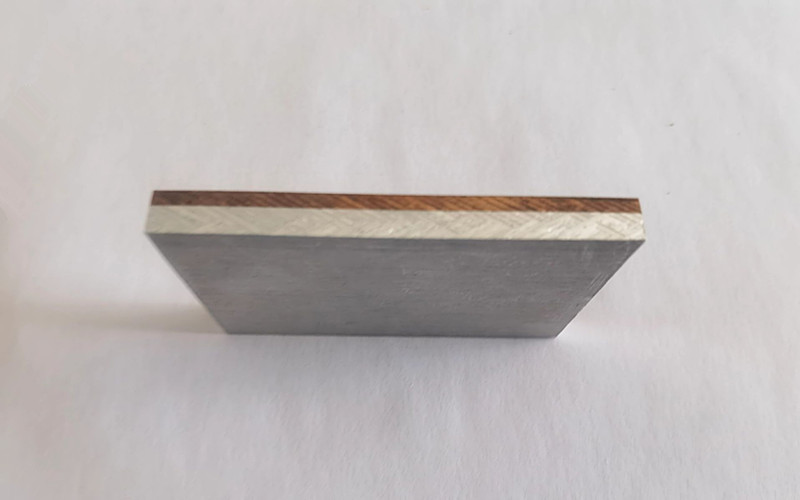

Material Composition & Structural Features

| Layer | Material | Properties |

| Aluminum Layer | EN AW-1050A (High-purity aluminum, 99.5%) | Lightweight, corrosion-resistant, good electrical conductivity |

| Copper Layer | Cu-ETP (Electrolytic Tough Pitch Copper | High electrical and thermal conductivity, good mechanical strength |

Thickness ratio: 1:1 (equal thickness for copper and aluminum layers)

Density: Approx. 5.8 g/cm³ (lower than pure copper, higher than pure aluminum)

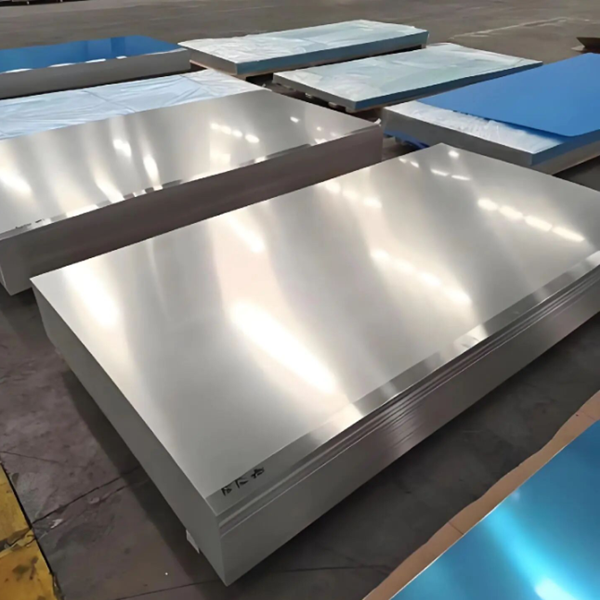

Cupal Metal Sheet Available Sizes

| Parameter | Range |

| Thickness | 0.2 mm – 6.0 mm |

| Width | 100 mm – 1000 mm |

| Length | 100 mm – 6000 mm |

Custom sizes, stamped parts, and pre-formed shapes are available upon request to meet specific industrial needs.

Why Choose Cu-Al Bimetallic Sheets?

Cupal sheets not only prevent electrochemical corrosion between copper and aluminum, but also offer the following key advantages:

High electrical and thermal conductivity – ideal for high-performance energy transfer

Lightweight – reduces total system weight compared to pure copper

Corrosion resistance – oxygen-free bonding prevents galvanic corrosion

Strong interlayer bonding – ensures long-term durability and reliability

Excellent processability – suitable for cutting, stamping, bending, and deep drawing

Consistent quality – supports continuous production for large-scale supply

These features make Cu-Al sheets a superior alternative to welding or mechanical joining in copper-aluminum interfaces.

Cupal Metal Sheet Applications

Electrical Industry

Busbars, connectors, terminals

Safe and reliable copper-to-aluminum connections

Energy Sector

Power transmission systems, transformers, substations

Reduce energy loss and improve system efficiency

Electronics

Circuit boards, grounding systems, surge protection

Mechanical & Structural Use

Washers, spacers for copper-aluminum joints

Prevent corrosion in bolted or welded structures

Get a Quote

Shenzhen Chinalco Metal offers stable and high-quality Cu-Al bimetallic sheets for busbar connectors, energy systems, and structural assemblies. Standard sizes and custom fabrication available. Contact us today to request a quote or technical support.