Aluminum welding wire TIG 7055 7075

Both 7055 and 7075 are high-strength aluminum alloys that are often used in aerospace, automotive, and other high-performance applications. When it comes to welding, the choice between 7055 and 7075 welding wire can significantly impact the quality and performance of the welds. Here’s a comparison of the two alloys in the context of TIG welding.

Aluminum welding wire 7055 7075 Standards

GB/T 10858-2008

GB/T3190-1996

AWS A5.10:1999

Comparison of 7055 vs 7075 Aluminum Welding Wire

Feature | 7055 | 7075 |

Composition | (Al): Balance (Zn): 6.0-7.0% (Mg): 2.0-2.6% (Cu): ≤1.2% (Cr): 0.18-0.25% Others: Small amounts of Titanium (Ti), Iron (Fe), Silicon (Si) | (Al): Balance (Zn): 5.1-6.1% (Mg): 2.1-2.9% (Cu): 1.2-2.0% (Cr): 0.18-0.28% Others: Small amounts of Titanium (Ti), Iron (Fe), Silicon (Si)

|

Wire Diameters | 1.2、1.6、2.0、2.4、3.0、4.0(mm) | 1.2、1.6、2.0、2.4、3.0、4.0(mm) |

Welding Applications | Aerospace, high-strength structures | Aerospace, military, high-performance vehicles |

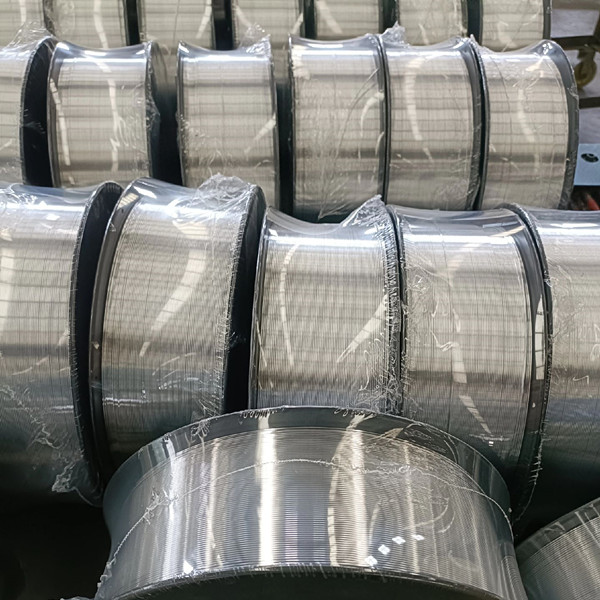

Aluminum welding wire 7055 7075 Wire Reel

* D300 (9 kg)

* D270 (7 kg)

Aluminum welding wire 7055 7075 Packaging Types

* Spool wire,

* straight bars,

* coil wire,

* bucket packaging

7055 Aluminum offers a better weldability compared to 7075, making it a more manageable choice for TIG welding. It’s still a high-strength material with good resistance to stress corrosion cracking, but it’s more forgiving when welding compared to 7075. This makes 7055 a good option for aerospace and high-performance automotive applications where strength and corrosion resistance are crucial.

7075 Aluminum, while offering superior strength, is more challenging to weld due to its susceptibility to hot cracking and high distortion. Special care is required in welding processes to minimize these issues, especially when welding thick sections or high-stress components. It is often used for aerospace and military applications where maximum strength is needed.

Applications of Aluminum welding wire 7055 7075

* Aerospace: Commonly used in aircraft frames, landing gear, high-stress aerospace components.

* Military: Applied in military-grade vehicles and equipment.

* Sports Equipment: Used for high-performance bicycle frames and recreational equipment.