4104/3003/4104 Aluminium Clad Brazing sheet

The aluminum clad welding sheet 4104/3003/4104 is a multilayer material designed for applications requiring excellent brazability, corrosion resistance, and moderate strength. It consists of a core material (3003 alloy) clad with 4104 alloy on both sides to enhance performance during welding or brazing processes.

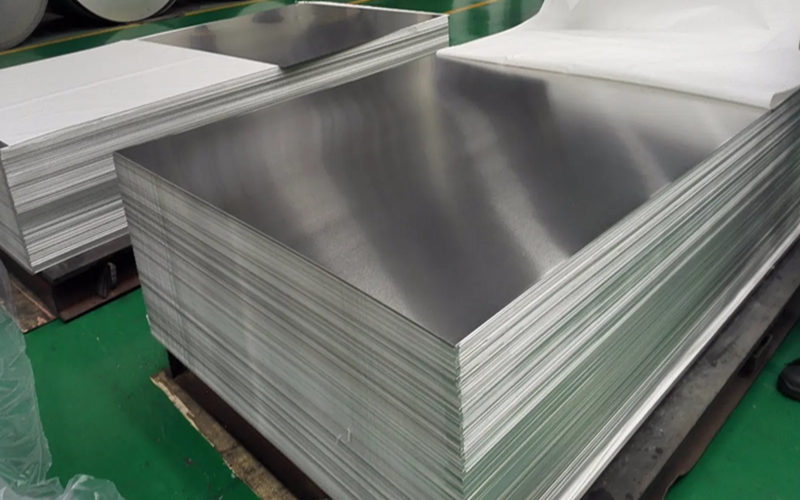

Typical Sizes for Aluminum Clad Brazing sheet 4104/3003/4104

Dimension Aluminum Clad Brazing sheet 4104/3003/4104 | |

Thickness | 0.8 mm -- 3.0 mm (clad layer included) |

Width | 100 mm -- 1500 mm |

Length | 500 mm-- 3000 mm (custom lengths available) |

Notes on Size Variations of Aluminum Clad Brazing sheet 4104/3003/4104

Clad Layer Thickness: The 4104 cladding layer typically constitutes 5% to 15% of the total thickness, depending on the application.

Custom Sizes: Custom dimensions may be produced to meet specific project requirements.

Key Features of Aluminum Clad Brazing sheet 4104/3003/4104

Brazability: The high-silicon cladding layer ensures excellent flow and bonding during brazing or welding.

Corrosion Resistance: Both the core (3003) and cladding layers (4104) provide resistance to general and localized corrosion.

Strength: The 3003 core provides moderate strength suitable for structural and thermal management applications.

Lightweight: Ideal for applications requiring a high strength-to-weight ratio.

Thermal Conductivity: Effective in heat exchange systems.

Material Structure of Aluminum Clad Brazing sheet 4104/3003/4104

Cladding Layers (Aluminum alloy 4104 )

Positioned on both the top and bottom surfaces.

Purpose: Provides excellent brazability, corrosion resistance, and a sacrificial layer to protect the core material.

Core Material (Aluminum alloy 3003)

Positioned in the center.

Purpose: Provides mechanical strength, ductility, and corrosion resistance.

Applications of Aluminum Clad Brazing sheet 4104/3003/4104

Automotive:

Heat exchangers (radiators, condensers, oil coolers).

Evaporators for air conditioning systems.

HVAC Systems:

Thermal management and heat exchanger applications.

Aerospace:

Lightweight and corrosion-resistant brazed assemblies.

Industrial:

Brazed plate heat exchangers for process industries.