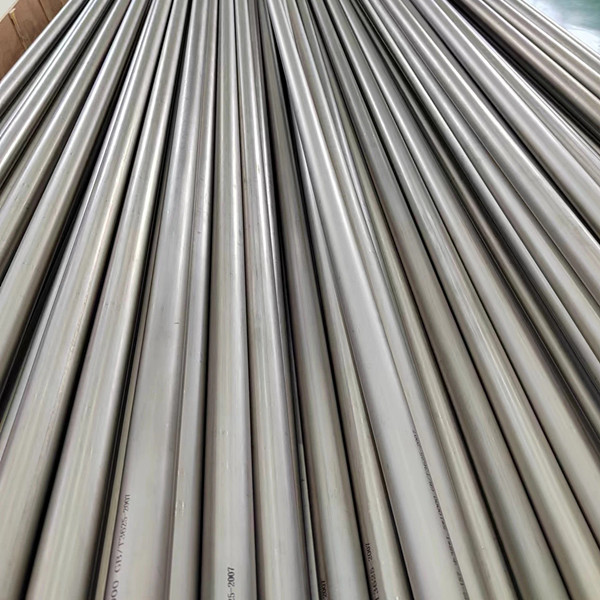

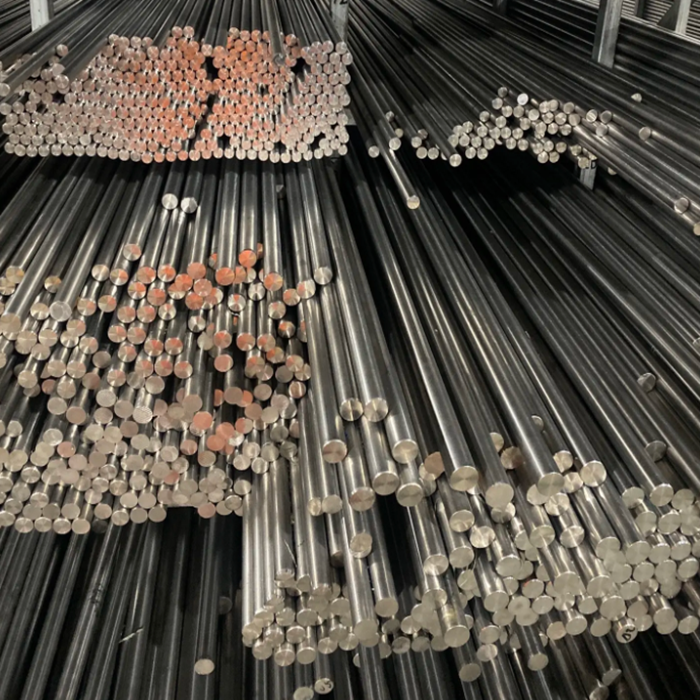

TA18 Grade9 Ti-3Al-2.5V Titanium Bar

Characteristics and Applications of TA18 Titanium Alloy

TA18 titanium alloy is an α-type titanium alloy with a nominal composition of Ti-3Al-2.5V. It was developed for applications requiring cold-worked tubing. At both room temperature and elevated temperatures, its strength is 20% to 50% higher than that of pure titanium. TA18 titanium alloy offers superior welding performance and cold-forming properties compared to the TC4 alloy. The maximum operating temperature for TA18 is approximately 315°C. Although its strength is not as high as that of the TC4 alloy, its excellent cold-working capabilities have led to widespread use.

TA18 Titanium Alloy Applications

TA18 titanium alloy are suitable for hydraulic and fuel systems in aircraft and engines. This alloy has been widely used in various military and civilian aircraft and aerospace applications due to its excellent cold-forming properties and reliability under operational conditions.

TA18 Titanium Alloy Chemical Composition

Element | Weight % |

Ti | Balance |

Al | 2.5~3.5 |

V | 2.0~3.0 |

C | 0.08 |

Fe | 0.25 |

N | 0.03 |

O | 0.15 |

H | 0.015 |

Titanium Alloy TA18 Grade 9 Ti-3Al-2.5V

Typical Mechanical Properties (Tensile Requirements)

Material | Tensile Strength, min | Yield Strength (0.2% Offset) min or range | Elongation in 4D, min % | Reduction of Area, min % | ||

Titanium Alloy Grade 9 Ti-3Al-2.5V | ksi | MPa | ksi | MPa | 15 | 25 |

90 | 620 | 70 | 483 | |||