High Purity 3N-5N5 Titanium ingot round bar

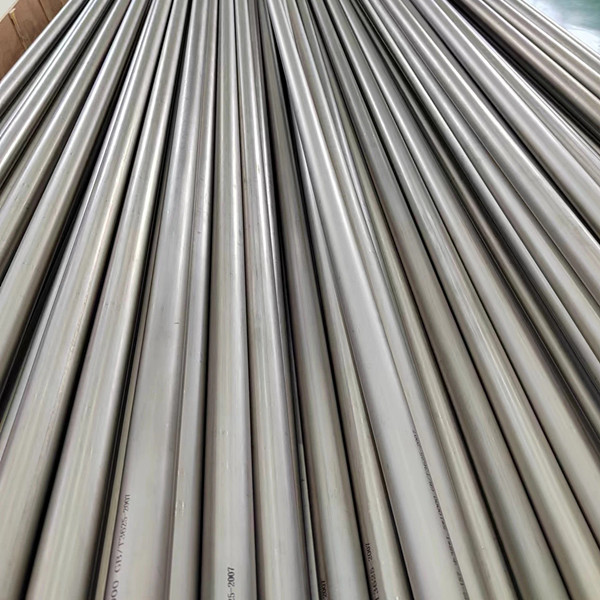

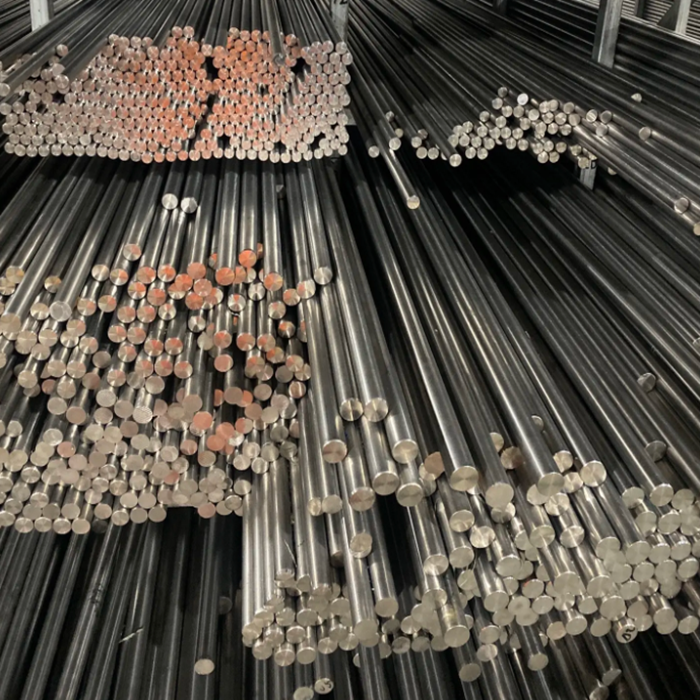

High-purity titanium bars (3N-5N5, 99.9%-99.9995%) are essential materials in the semiconductor industry, offering exceptional purity to minimize contamination and enhance yield in chip production. They feature excellent corrosion resistance for harsh chemical environments, low thermal expansion for dimensional stability, and superior thermal conductivity for effective heat management. Additionally, their non-magnetic properties prevent electromagnetic interference, crucial for precision manufacturing. With high machinability and surface quality, these bars are ideal for producing vacuum chambers, sputtering targets, and precision components, supporting processes like CVD and thin-film deposition. Environmentally friendly and recyclable, they align with sustainability goals in advanced semiconductor manufacturing.

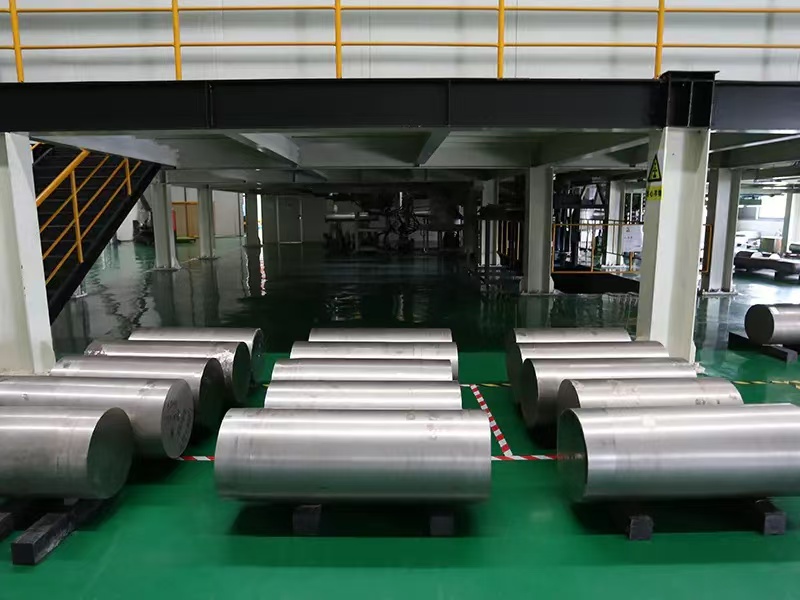

Size of High Purity Titanium Round Bar

Size : | Min.15mm, Max Diameter 800mm ; |

Weight : | Max 1500kgs; |

MOQ : | 100kgs |

Package : | Export wooden pallet |

Usage: | Semiconductor industrial |

Composition of High Purity Titanium Round Bar

Desp. | 3N | 3N5 | 4N | 4N5 | 5N | 5N5 | % [wt] | Test M. |

Ti | ≥99.9 | ≥99.95 | ≥99.99 | ≥99.995 | ≥99.999 | ≥99.9995 | ||

Ag | - | - | 1 | 0.5 | 0.01 | 0.01 | ppm [wt] | GDMS |

Al | - | 50 | 10 | 3 | 2 | 2 | ppm [wt] | GDMS |

As | - | - | 10 | 1 | 0.5 | 0.5 | ppm [wt] | GDMS |

Au | - | - | 1 | 0.5 | 0.25 | 0.25 | ppm [wt] | GDMS |

B | - | 1 | - | 0.1 | 0.05 | 0.05 | ppm [wt] | GDMS |

Be | - | - | - | 0.5 | 0.5 | 0.5 | ppm [wt] | GDMS |

Bi | - | - | - | 0.1 | 0.05 | 0.05 | ppm [wt] | GDMS |

Ca | - | - | 1 | 1 | 0.5 | 0.5 | ppm [wt] | GDMS |

Cd | - | - | - | 1 | 0.2 | 0.2 | ppm [wt] | GDMS |

Cl | 600 | 10 | 5 | 1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Co | - | - | 5 | 1 | 0.05 | 0.05 | ppm [wt] | GDMS |

Cr | - | 20 | 5 | 1 | 0.8 | 0.8 | ppm [wt] | GDMS |

Cu | - | 50 | 5 | 2 | 1 | 1 | ppm [wt] | GDMS |

F | - | - | - | 15 | 0.5 | 0.5 | ppm [wt] | GDMS |

Fe | 700 | 200 | 10 | 7 | 5 | 3 | ppm [wt] | GDMS |

Hg | - | - | - | 0.5 | 0.5 | 0.1 | ppm [wt] | GDMS |

K | - | 0.1 | 0.1 | 0.05 | 0.05 | 0.01 | ppm [wt] | GDMS |

Li | - | 0.1 | 0.1 | 0.05 | 0.05 | 0.005 | ppm [wt] | GDMS |

Mg | - | 1 | 2 | 1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Mn | - | 10 | 5 | 1 | 1 | 0.5 | ppm [wt] | GDMS |

Mo | - | - | 4 | 1 | 0.05 | 0.05 | ppm [wt] | GDMS |

Na | - | - | 0.2 | 0.03 | 0.03 | 0.03 | ppm [wt] | GDMS |

Ni | 250 | 25 | 5 | 1 | 0.5 | 0.5 | ppm [wt] | GDMS |

P | - | - | - | 1 | 0.25 | 0.01 | ppm [wt] | GDMS |

Pb | - | - | - | 1 | 0.1 | 0.01 | ppm [wt] | GDMS |

Pd | - | - | - | 0.1 | 0.1 | 0.01 | ppm [wt] | GDMS |

S | - | - | 10 | 10 | 5 | 3 | ppm [wt] | GDMS |

Sb | - | - | 7 | 0.5 | 0.5 | 0.05 | ppm [wt] | GDMS |

Si | 200 | 50 | 5 | 2 | 1 | 1 | ppm [wt] | GDMS |

Sn | - | - | 5 | 1 | 0.5 | 0.01 | ppm [wt] | GDMS |

Te | - | - | - | 0.5 | 0.5 | 0.05 | ppm [wt] | GDMS |

Th | - | 0.001 | 0.001 | 0.0005 | 0.0001 | 0.0001 | ppm [wt] | GDMS |

U | - | 0.001 | 0.001 | 0.0005 | 0.0001 | 0.0001 | ppm [wt] | GDMS |

V | - | - | - | 1 | 1 | 1 | ppm [wt] | GDMS |

W | - | - | - | 1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Zn | - | - | 5 | 1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Zr | - | - | 5 | 3 | 1 | 1 | ppm [wt] | GDMS |

Ba | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Br | - | - | - | 0.5 | 0.5 | 0.5 | ppm [wt] | GDMS |

Ce | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Cs | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Ga | - | - | - | 0.5 | 0.5 | 0.5 | ppm [wt] | GDMS |

Ge | - | - | - | 0.5 | 0.5 | 0.5 | ppm [wt] | GDMS |

Hf | - | - | - | 1 | 1 | 1 | ppm [wt] | GDMS |

I | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

In | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

La | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Pt | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Re | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Rh | - | - | - | 0.2 | 0.2 | 0.2 | ppm [wt] | GDMS |

Ru | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Sc | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Se | - | - | - | 0.5 | 0.5 | 0.5 | ppm [wt] | GDMS |

Pr | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Nd | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Sm | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Eu | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Gd | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Tb | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Dy | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Ho | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Er | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Tm | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Yb | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Lu | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Os | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Ir | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Pt | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

Tl | - | - | - | 0.1 | 0.1 | 0.1 | ppm [wt] | GDMS |

C | 200 | 150 | 50 | 30 | 30 | 30 | ppm [wt] | LECO |

H | 50 | 10 | 5 | 10 | 6 | 6 | ppm [wt] | LECO |

N | 200 | 100 | 50 | 30 | 30 | 30 | ppm [wt] | LECO |

O | 800 | 700 | 450 | 300 | 200 | 100 | ppm [wt] | LECO |