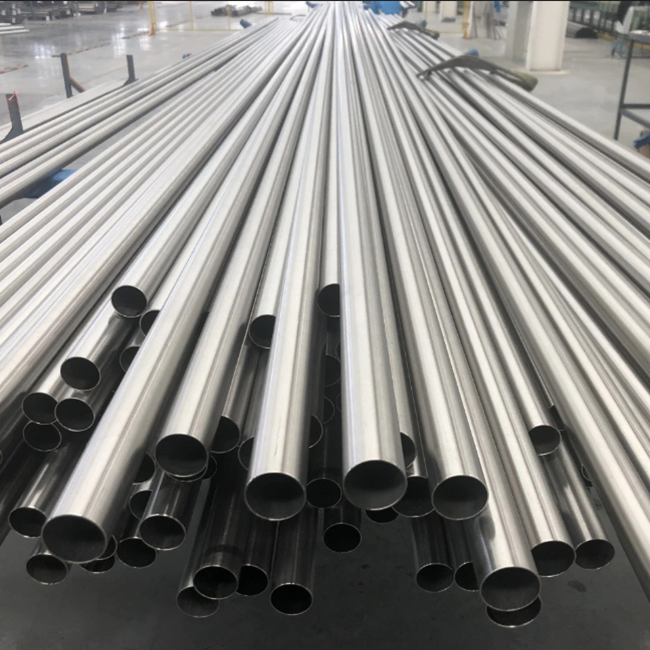

ASTM B861 Pure Titanium TA1 Grade 1 Seamless Pipe

TA1 Seamless Titanium Pipes (Commercially Pure Grade 1 Titanium) are widely used in industries where corrosion resistance, lightweight, and biocompatibility are essential.

Size for Pure Titanium TA1 Grade 1 Seamless Pipe

Titanium TA1 Grade 1 Seamless Pipe | Size |

Outer Diameter (OD) | OD :3 mm – 120mm ( larger) |

Wall Thickness (WT) | WT :0.5 mm – 10 mm (thicker) |

Length | 100mm --6000mm (custom lengths available) |

Chemical Composition of Pure Titanium TA1 Grade 1 Seamless Pipe

Element | Maximum Content (%) |

Titanium (Ti) | ~99.5 (minimum) |

Oxygen (O) | 0.18 |

Nitrogen (N) | 0.03 |

Carbon (C) | 0.08 |

Hydrogen (H) | 0.015 |

Iron (Fe) | 0.2 |

Standards of Pure Titanium TA1 Grade 1 Seamless Pipe

l ASTM B861: Standard Specification for Seamless Titanium and Titanium Alloy Pipe.

l ASTM B338: Standard Specification for Seamless Titanium Tubes for Heat Exchangers and Condensers.

l ISO 5832-2: Standard for Medical-Grade Titanium.

l DIN 17860: Standard for Titanium and Titanium Alloy Tubes.

l AMS 4902: Aerospace Material Specification for Titanium Pipes.

Mechanical Properties of Pure Titanium TA1 Grade 1 Seamless Pipe

Property | Value |

Tensile Strength | 240 MPa (minimum) |

Yield Strength | 140 MPa (minimum) |

Elongation | 24% (minimum) |

Density | 4.51 g/cm³ |

Modulus of Elasticity | 103 GPa |

Manufacturing Processes of Pure Titanium TA1 Grade 1 Seamless Pipe

Extrusion: For initial forming of the Pure Titanium TA1 Grade 1 Seamless Pipe.

Cold Rolling or Cold Drawing: To achieve desired dimensions and improve surface finish.

Heat Treatment: Annealing to enhance ductility and mechanical properties.

Surface Finishing of Pure Titanium TA1 Grade 1 Seamless Pipe

Pickling: Removes oxide layers and ensures a clean surface.

Polishing: For improved aesthetics or to meet medical-grade standards.

Sandblasting: To provide a uniform matte finish.

Why Choose Pure Titanium TA1 Grade 1 Seamless Pipe?

No Weld Seams:

Seamless tubes are formed from a solid billet of titanium, which is extruded or drawn to form the tube shape without any welded seams. This eliminates the potential for weak points associated with welds.

Improved Corrosion Resistance:

The absence of seams ensures there are no potential areas for localized corrosion, especially in harsh environments such as seawater or chemical processing.

Higher Strength:

Seamless tubes maintain uniform wall thickness and a consistent structure throughout, which can result in better strength, higher pressure tolerance, and greater resistance to fatigue.

Better Dimensional Precision:

Seamless tubes offer tighter dimensional tolerances, which is crucial for many industries where precise dimensions are required.

Ideal for High-Pressure Applications:

Due to the uniform strength and integrity, seamless tubes are ideal for applications requiring high pressure, such as in heat exchangers, reactors, and other high-stress environments.

Typical Applications of Pure Titanium TA1 Grade 1 Seamless Pipe

Chemical Industry: Corrosion-resistant piping systems for strong acids, alkalis, and salts.

Aerospace: Fuel lines, hydraulic systems, and structural components.

Marine: Seawater piping and heat exchangers.

Medical: Implants, surgical instruments, and biocompatible components.

Energy: Heat exchangers in power plants.