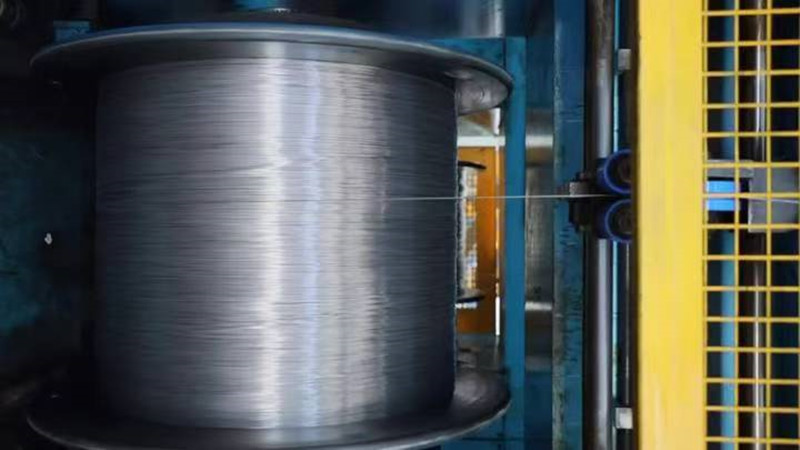

Gr9 Ti-3Al-2.5V Titanium wire

Gr9 Titanium (Ti-3Al-2.5V) offers a well-balanced set of properties, including moderate strength, good ductility, and excellent corrosion resistance. This alloy is widely used in aerospace, marine, chemical processing, and medical applications where high strength, resistance to corrosion, and lightweight properties are essential. Additionally, its good weldability and formability make it an ideal choice for manufacturing in various wire forms.

Sizes of Gr9 Ti-3Al-2.5V Titanium wire

Ti-3Al-2.5V wire (Gr9) is available in various forms, including:

l Wire Diameter: Typically ranging from 0.1 mm to 6 mm, depending on specific requirements.

l Wire Length: Available in spools, cut lengths, or custom lengths depending on application needs.

Property | Value/Description |

Alloy | Ti-3Al-2.5V (Titanium 3% Aluminum, 2.5% Vanadium) |

Composition | 3% Aluminum, 2.5% Vanadium, Balance Titanium |

Tensile Strength | 825-1,000 MPa |

Yield Strength | 780-950 MPa |

Elongation | 12-18% |

Corrosion Resistance | Excellent in marine, chemical, and industrial environments |

Applications | Aerospace, marine, chemical processing, sports equipment, medical |

Wire Sizes | Diameters : 0.1 mm -- 6 mm |

Corrosion Resistance of Gr9 Ti-3Al-2.5V Titanium wire

Gr9 Titanium (Ti-3Al-2.5V) has excellent corrosion resistance similar to other titanium alloys. It resists pitting, crevice, and stress corrosion cracking in seawater, chlorides, sulfuric acid, and other corrosive environments.

The alloy is also resistant to oxidation at elevated temperatures, which makes it suitable for applications where the material might be exposed to harsh chemical conditions or high temperatures.

Chemical Composition of Gr9 Ti-3Al-2.5V Titanium Alloy Wire

Element | Composition |

Titanium (Ti) | Balance (min 90%) |

Aluminum (Al) | 3.00% |

Vanadium (V) | 2.50% |

Iron (Fe) | 0.25% (max) |

Oxygen (O) | 0.20% (max) |

Carbon (C) | 0.08% (max) |

Hydrogen (H) | 0.015% (max) |

Nitrogen (N) | 0.03% (max) |

Applications of Gr9 Ti-3Al-2.5V Titanium Wire

· Aerospace: Gr9 titanium alloy is used in aircraft components, such as structural parts, landing gears, and airframe materials, where a combination of strength, lightweight, and corrosion resistance is essential.

· Marine: Commonly used in marine structures and components exposed to seawater and harsh marine environments due to its superior corrosion resistance.

· Chemical Processing: This alloy is used in chemical processing equipment, including heat exchangers, reactors, and valves, where excellent corrosion resistance is needed.

· Sports Equipment: Gr9 titanium wire is sometimes used in the production of high-performance bicycle frames, sports gear, and other equipment where strength and low weight are critical.

· Medical: Ti-3Al-2.5V is used in medical devices, including implants and surgical instruments, due to its biocompatibility and good mechanical properties.