Aluminum Honeycomb Panel Application

What Is an Aluminum Honeycomb Panel?

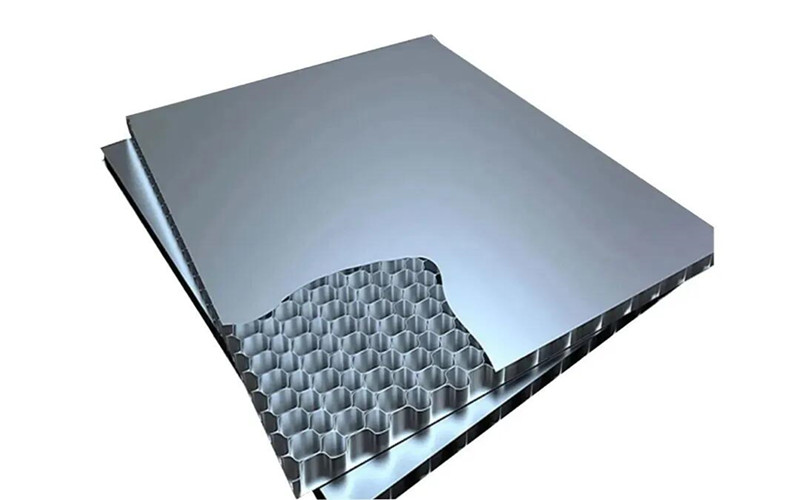

An aluminum honeycomb panel is a type of lightweight structural panel made by sandwiching an aluminum honeycomb core between two thin aluminum sheets. The core is shaped like a honeycomb — a structure inspired by nature that offers high strength with minimal material. This design allows the panel to be extremely stiff while staying incredibly light.

Depending on its purpose, the outer skins can be made of aluminum, stone veneer, high-pressure laminate (HPL), or other materials. This versatility makes it suitable for a wide range of applications in construction, transportation, and industrial design.

You might also come across terms like aluminum honeycomb wall panel, aluminum honeycomb composite panel, or aluminum honeycomb sandwich panel — these all refer to variations of the same basic concept, optimized for different uses.

How Strong Are Aluminum Honeycomb Panels?

Despite being lightweight, honeycomb aluminum panels are known for their impressive strength. The secret lies in the internal hexagonal core, which evenly spreads loads and resists bending or crushing.

Compression Strength: Excellent for bearing weight without deformation

Shear Strength: Can resist sliding forces, making it ideal for structural uses

Flexural Rigidity: Maintains flatness over large spans without sagging

Impact Resistance: Especially when paired with thicker skins or reinforced surfaces

This makes aluminum honeycomb panels perfect for environments where strong yet light materials are essential — such as aircraft interiors or high-rise building facades.

Advantages and Disadvantages of Aluminum Honeycomb Panels

Like any material, aluminum honeycomb composite panels have their advantages and limitations.

Advantages

Lightweight and easy to install

High strength-to-weight ratio

Naturally corrosion-resistant

Excellent fire performance

Fully recyclable and environmentally friendly

Good thermal and sound insulation properties

Disadvantages

Higher production cost compared to solid aluminum sheets

Risk of delamination if bonding is poorly done

May dent under heavy point loads if outer skins are thin

Despite these drawbacks, the benefits often outweigh the limitations — especially in projects where performance and weight reduction are top priorities.

Applications of Aluminum Honeycomb Panels

Thanks to their versatility and excellent mechanical properties, aluminum honeycomb sandwich panels are widely used in the following sectors:

Architecture and Building Facades

In modern construction, aluminum honeycomb wall panels are a popular choice for:

Building facades, curtain walls and cladding

Interior walls and partitions

Ceilings, columns, and elevator surrounds

Doors, countertops, and furniture panels

Architects favor these panels for their sleek appearance, flat surface, and fire resistance. They're especially useful in high-rise buildings where reducing dead load is critical. Long-tail keywords like lightweight architectural cladding and non-combustible aluminum panels often relate to these use cases.

Vehicles and Transportation

From airplanes and trains to buses and electric vehicles, honeycomb aluminum panels help reduce vehicle weight without compromising strength. Applications include:

Aircraft floors and bulkheads

Train walls and partitions

Bus ceiling panels and luggage racks

Marine deck panels and cabin walls

Using aluminum honeycomb core panels helps lower fuel consumption, improve structural stability, and meet strict weight limits. This is why they’re common in industries that prioritize energy efficiency and lightweight engineering.

Acoustic and Soundproofing Solutions

When used with perforated skins or sound-absorbing materials, aluminum honeycomb acoustic panels offer excellent noise reduction. Common applications include:

Conference rooms and theaters

Studio walls and ceilings

Machinery enclosures and control rooms

High-speed train interiors

These panels trap and dampen sound waves inside the honeycomb cells, offering a lightweight solution for acoustic comfort — especially in commercial or industrial buildings.

Conclusion

Whether you are building a high-rise, designing a luxury train interior, or upgrading a studio’s acoustics, aluminum honeycomb panels offer a reliable, durable, and efficient solution. Their unique core structure delivers exceptional performance with minimal material, aligning with modern demands for sustainability and lightweight design.

Shenzhen Chinalco Metal provides high-quality aluminum honeycomb panels, customized to your specifications. We welcome inquiries for construction, transportation, or soundproofing projects — let us help you find the best panel solution for your needs.

Contact us today to learn more or request a sample.