What Can Cold Drawn Aluminum Tube Be Used For?

Cold drawn aluminum tube is a versatile material widely used across many industries. Known for its high precision, smooth surface finish, excellent mechanical strength, and lightweight properties, it has become a reliable choice for many manufacturers. Thanks to these advantages, cold drawn aluminum tubing plays a key role in sectors like aerospace, automotive, machinery, construction, sports equipment, and medical devices.

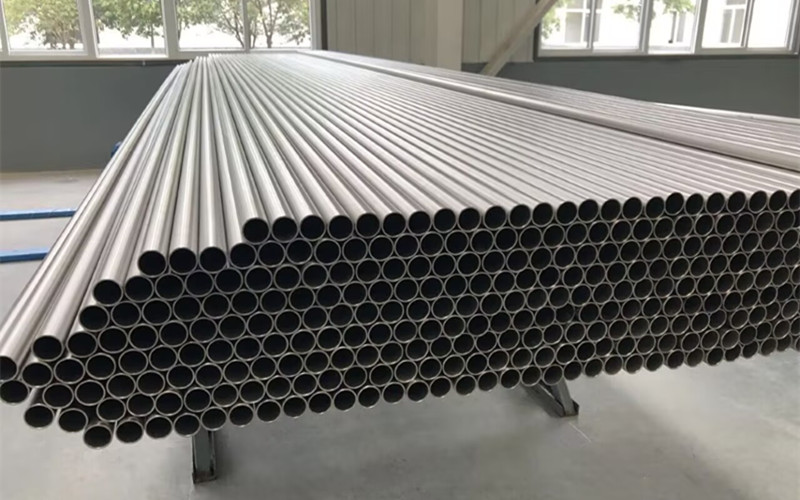

What Is Cold Drawn Aluminum Tube?

Cold drawn aluminum tube is produced by pulling an aluminum tube through a die at room temperature. This process reduces the diameter, increases the length, and greatly improves the tube’s surface quality and dimensional accuracy. Because it is performed without additional heating, the finished tube maintains a fine-grain structure and higher mechanical strength compared to hot-worked tubes.

Cold drawn tubes are especially valued for their consistent quality, lightweight nature, and ease of machining or surface treatment, making them ideal for precision engineering and demanding applications.

Applications of Cold Drawn Aluminum Tube

Aerospace Industry

In the aerospace industry, strength, precision, and weight reduction are critical. Cold drawn aluminum tubes are used in aircraft structural components, fuel systems, hydraulic systems, and support frameworks. Lightweight but strong, these tubes help improve fuel efficiency and enhance aircraft performance. Common grades used in aerospace applications include 3003, 5052, and 7075, offering a balance of formability, corrosion resistance, and high strength.

Automotive Industry

Cold drawn aluminum tubing plays a major role in automotive design and manufacturing. It is used for crash management systems, drive shafts, structural frames, and cooling system components. Its corrosion resistance and low weight help improve fuel efficiency and extend vehicle lifespan. Precision-formed aluminum tubes allow engineers to create safer, lighter, and more durable automotive systems without compromising performance.

Industrial Equipment and Machinery

In industrial settings, cold drawn aluminum tubes are essential for equipment that demands precision and durability. Applications include pneumatic cylinders, hydraulic systems, conveyor systems, and parts for industrial automation. The smooth internal and external surfaces of cold drawn tubing reduce friction and wear, improving the lifespan and reliability of machinery. Their consistent dimensions also make installation and maintenance much easier.

Construction and Architecture

Construction projects benefit from the strength, appearance, and corrosion resistance of cold drawn aluminum tubes. They are commonly used in building frameworks, curtain wall systems, handrails, window frames, and decorative structures. Thanks to their smooth surface and easy fabrication, architects and builders choose aluminum tubing when they need both functional performance and an attractive finish.

Sports and Recreation Equipment

Sports equipment manufacturers frequently use cold drawn aluminum tubing to achieve strong yet lightweight designs. Bicycles, camping gear, ski poles, and even lightweight trailers often incorporate cold drawn tubes. In particular, cyclists appreciate aluminum frames for their responsiveness, strength, and corrosion resistance, offering better performance over time compared to heavier materials.

Medical Devices

Cold drawn aluminum tubing also plays an important role in the medical field. It is used in hospital beds, wheelchairs, mobility aids, and certain surgical instruments. The smooth surface finish ensures easy cleaning and sanitation, while the material’s lightweight nature makes medical devices easier to handle and transport. Precision is critical in medical applications, and cold drawn tubes provide the reliability needed for patient safety and comfort.

Why Choose Cold Drawn Aluminum Tube?

There are several reasons why industries choose cold drawn aluminum tubing:

High dimensional accuracy for critical assemblies

Smooth surface finish suitable for cosmetic and functional needs

Superior mechanical properties for high-load applications

Lightweight design to improve energy efficiency and portability

Excellent corrosion resistance for extended service life

Whether you need precision tubing for aerospace components or strong, lightweight materials for automotive systems, cold drawn aluminum tubes provide a solution that meets high performance and reliability standards.

Conclusion

Cold drawn aluminum tubes are trusted across a wide range of industries for their precision, strength, and versatility. They enable better designs, longer product lifespans, and improved performance in fields as varied as aerospace, automotive, industrial machinery, construction, sports equipment, and healthcare.

If you are looking for a trusted aluminum supplier with a wide aluminum stock and expertise in aluminum metal processing, Shenzhen Chinalco Metal is ready to support your needs. We offer a variety of cold drawn aluminum tubing in different grades and sizes. Contact us today for more information or to request a quote!