Is 7075 Aluminum Be Clad?

7075 aluminum alloy is a high-strength aluminum alloy widely used in aerospace, automotive, marine, and other fields. It has excellent strength and hardness. Common cladding materials include 1100 series or 3003 series aluminum alloys, which have better ductility and corrosion resistance.

Although 7075-T6 aluminum alloy itself has very high strength, its corrosion resistance is relatively poor. Therefore, in some applications, cladding technology is used to improve its corrosion resistance. Cladding materials are usually purer aluminum or aluminum alloys with better corrosion resistance, such as the 1100 or 3003 series.

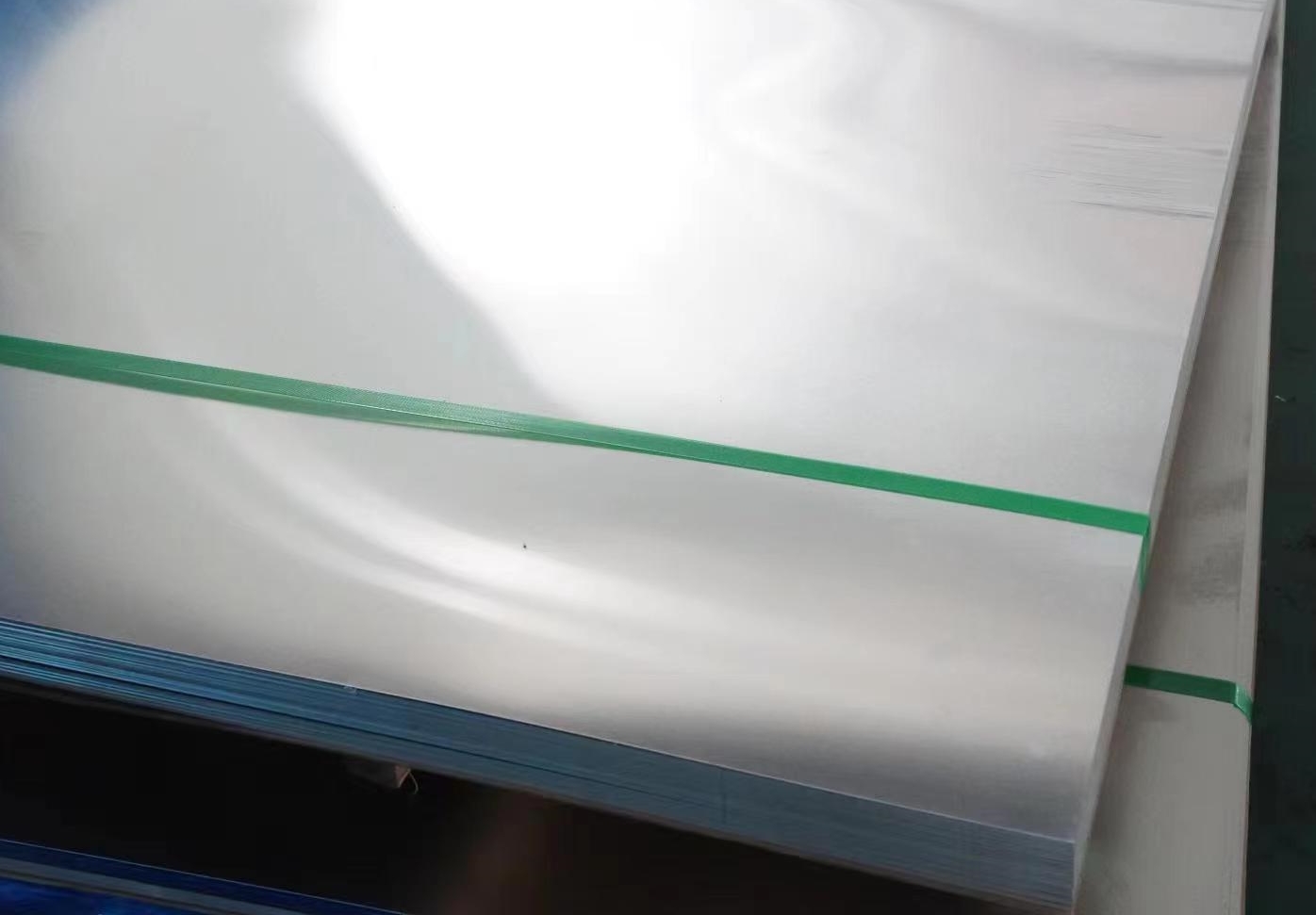

This cladding process, known as "cladding," involves covering the surface of the 7075-T6 aluminum alloy with a thin layer of corrosion-resistant aluminum. The benefits of this process include:

Improved corrosion resistance: The cladding layer provides excellent corrosion protection, preventing the 7075-T6 substrate from being damaged in corrosive environments.

Retention of substrate strength: The cladding layer is very thin and does not significantly affect the mechanical properties of the 7075-T6 aluminum alloy, thus retaining its high-strength characteristics.

Extended service life: The cladding process can significantly extend the service life of 7075-T6 aluminum alloy products, especially in harsh environments.

Therefore, although 7075-T6 itself is not suitable for use as a cladding material, cladding its surface with a layer of corrosion-resistant aluminum material is a common and effective practice.