Aluminum 6101 Thermal Conductivity and Electrical Conductivity

Thermal Conductivity, Electrical Conductivity , and Applications of Aluminum Alloy 6101

Aluminum alloy 6101 is characterized by its high electrical and thermal conductivity, making it a valuable material in modern industrial and engineering fields. It plays an indispensable role, especially in the electrical and automotive sectors. This article provides an in-depth analysis of the thermal conductivity, electrical conductivity, thermal expansion coefficient, applications in automotive heat sinks, and other uses of aluminum alloy 6101.

1. Thermal Conductivity of Aluminum Alloy 6101

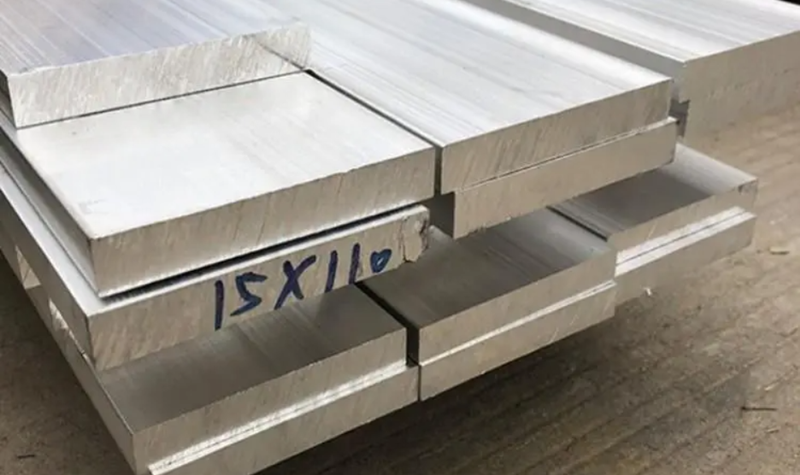

Aluminum alloy 6101 exhibits excellent thermal conductivity, typically ranging between 167 and 205 W/(m·K). While slightly lower than pure aluminum, it meets the demands of most high-thermal-conductivity scenarios. The chemical composition of 6101 is optimized to maintain good thermal performance without compromising strength. This property makes the alloy ideal for applications requiring efficient heat transfer and dissipation.

2. Electrical Conductivity of Aluminum Alloy 6101

The electrical conductivity of aluminum alloy 6101 is equally remarkable, with a conductivity rate typically reaching 52% IACS (International Annealed Copper Standard). This property makes it a critical material in the electrical sector, widely used in power transmission lines, busbars, and other efficient power systems. Compared to traditional copper materials, 6101 offers significant economic and technical advantages by combining excellent conductivity with lighter weight and lower costs.

3. Thermal Expansion Coefficient

The thermal expansion coefficient of aluminum alloy 6101 is approximately 23.6 × 10^-6 /K (within the temperature range of 20–100℃). This value indicates good stability under thermal expansion, making it compatible with other structural components, especially in applications requiring high thermal performance and mechanical integration.

4. Suitability for Heat Sinks

Thanks to its high thermal conductivity, excellent electrical conductivity, moderate thermal expansion coefficient, and low density, aluminum alloy 6101 is an ideal material for manufacturing heat sinks. Its advantages include:

Efficient Heat Dissipation: Excellent thermal conductivity allows rapid heat transfer from the source to the environment.

High Electrical Conductivity: Performs exceptionally well in scenarios requiring both thermal and electrical properties.

Good Machinability: 6101 alloy can be easily extruded and processed into complex heat sink shapes.

Lightweight Design: With a density of only 2.7 g/cm³, it is perfect for weight-sensitive applications such as automotive radiators and electronic cooling modules.

Corrosion Resistance: Anodic oxidation treatment forms a dense oxide film on the aluminum surface, further enhancing durability and appearance.

In the automotive sector, aluminum alloy 6101 is widely used in engine heat sinks and electric vehicle battery cooling systems. Its applications are expanding rapidly with the growth of the electric vehicle industry.

5. Applications in the Automotive Sector

The use of aluminum alloy 6101 in the automotive industry extends beyond heat sinks to include the following:

Electrical Conductors: Due to its high electrical conductivity, 6101 is commonly used as a conductor material in automotive electrical systems, such as busbars and cables.

Structural Components: Lightweight design is a critical goal for the automotive industry. With moderate strength and low weight, 6101 alloy is used to manufacture load-bearing components.

Battery Cooling Systems: Efficient heat dissipation is essential for electric vehicle battery modules, and 6101 meets these requirements with its superior thermal conductivity and durability.

6. Applications in Other Fields

In addition to the automotive industry, aluminum alloy 6101 has a wide range of applications in other fields:

Electrical Engineering: Widely used in power transmission lines, substations, and busbars to improve efficiency and reduce energy loss.

Electronic Heat Sinks: Frequently selected for chip cooling in computers and other high-performance electronic devices to ensure efficient heat dissipation.

Construction: With good strength and corrosion resistance, 6101 is used in window frames, roofs, and other building structures.

Aerospace: The alloy’s lightweight and high conductivity make it suitable for aerospace applications where these properties are critical.

Renewable Energy: In solar and wind energy equipment, 6101 is used for critical components such as solar brackets and wiring systems due to its conductivity and corrosion resistance.

7. Conclusion

In summary, aluminum alloy 6101’s high thermal and electrical conductivity, moderate thermal expansion coefficient, and excellent machinability make it the material of choice for heat sinks and other lightweight structural components. Its high practical value is evident across the automotive, electrical, electronic, construction, and aerospace industries. As technology continues to advance and market demands evolve, the application prospects for aluminum alloy 6101 will become even broader.