How to Cut Aluminum Plate?

How to Choose Cutting Method for Aluminum Plates

Aluminum plates are widely used materials in industries ranging from aerospace to home decor. Choosing the right cutting method during processing is crucial, as it impacts not only efficiency but also the precision and appearance of the final product. This article provides a detailed guide to cutting methods for aluminum plates of various thicknesses, with practical examples to help you make the best choice.

1. How to cut standard-thickness aluminum plates?

Standard-thickness aluminum plates typically range from 1 to 10 millimeters. Cutting such plates requires a balance between efficiency and precision. Below are some commonly used methods:

Metal Cutting Saw

A metal cutting saw equipped with a blade designed specifically for aluminum alloys is a common and efficient option.

Example: A machinery manufacturer needed to cut 8 mm aluminum plates in bulk. Using a metal cutting saw increased efficiency by 30% and produced clean cuts, reducing post-processing requirements.

Handheld Hacksaw

For thinner plates, especially in small-scale or DIY projects, manual cutting is a cost-effective and practical option. Though slower, it does not require expensive machinery.

Example: A DIY enthusiast used a handheld hacksaw to cut 2 mm aluminum plates for garden decoration frames, saving costs while ensuring smooth edges.

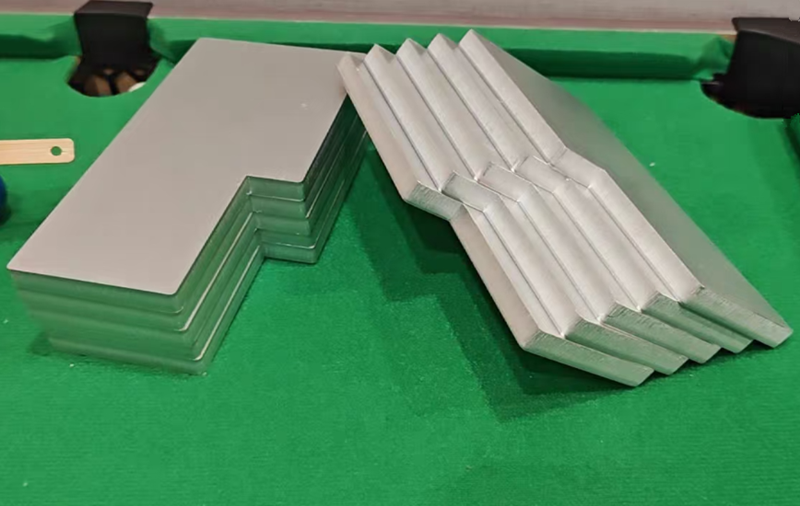

Automated Aluminum Plate Cutting Machine

Equipped with features like automatic feeding, clamping, and positioning, these machines are controlled by PLC systems for high-precision cutting.

Example: An electronics company used an automated cutting machine to process 5 mm aluminum plates, increasing batch production by 40% and achieving burr-free edges.

2. How to cut thick aluminum plates?

Thick aluminum plates (10 mm or more) require robust equipment and techniques to handle the increased cutting difficulty. Below are suitable methods for different requirements:

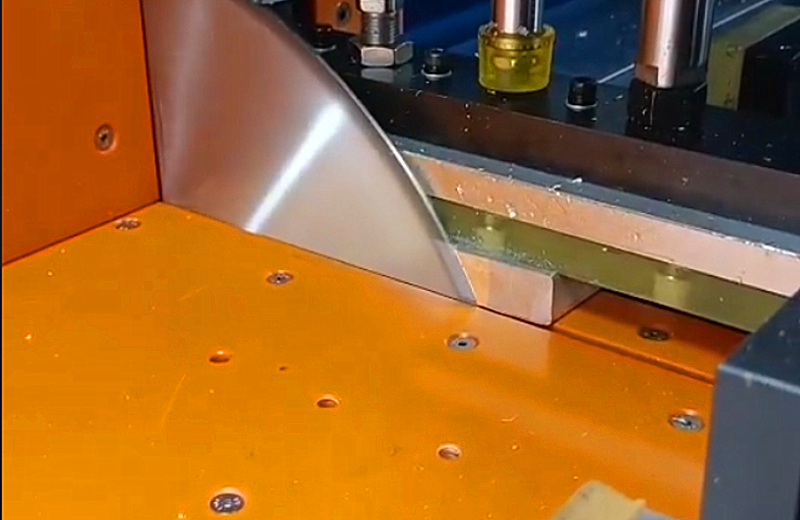

Shearing Machine

This tool provides fast, deformation-free straight cuts, making it ideal for plates over 10 mm thick.

Example: An aerospace manufacturer used a shearing machine to cut 12 mm aluminum plates for wing components, significantly reducing initial processing time.

Plasma Cutter

Plasma cutters can handle curved cuts on plates 20 mm or thicker. However, they may cause deformation and require additional post-processing.

Example: In an art project, a designer used a plasma cutter to create intricate curves on 30 mm aluminum plates, achieving unique sculptural shapes.

Wire EDM

Although slower, wire EDM (Electrical Discharge Machining) offers exceptional precision, especially for plates 30 mm or thicker.

Example: A mold manufacturer used wire EDM to cut 50 mm aluminum plates for high-precision mold components, meeting stringent tolerance requirements.

Fiber Laser Cutting Machine

Known for its smooth cuts, high speed, and accuracy, laser cutting is suitable for aluminum plates of various thicknesses.

Example: A luxury home decor brand used a fiber laser cutter to process 15 mm aluminum plates, delivering oxidation-ready surfaces without additional polishing.

3. How to choose better cutting method for aluminum plate?

Selection Based on Thickness:

| Thickness Range (mm) | Recommended Cutting Methods | Advantages |

1–5 | Hacksaw, automated cutting machine | Cost-effective, suitable for small projects |

5–10 | Metal cutting saw, automated cutter | High efficiency, automation |

10–20 | Shearing machine, laser cutter | Fast, deformation-free |

20–30 | Plasma cutter, wire EDM | Curved cutting, high precision |

30+ | Fiber laser cutter, wire EDM | High-precision, complex shapes |

Factors to Consider:

Efficiency: For batch production, prioritize automated tools like laser cutters or aluminum cutting machines.

Precision: For high-precision needs, wire EDM or laser cutters are preferred.

Cost: For small-scale or home projects, handheld hacksaws and manual tools are more economical.

4. Best way to cut aluminum plate

Different aluminum plate thicknesses and applications require tailored cutting methods:

Standard-thickness plates: Metal cutting saws or automated cutting machines are recommended for their simplicity and efficiency.

Thick plates: Shearing machines are ideal for straight cuts, while plasma cutters and wire EDM excel at curved cutting. Fiber laser cutters are suitable for high-precision requirements.

By choosing the appropriate cutting method, you can significantly enhance processing efficiency and product quality, adding value to your projects.