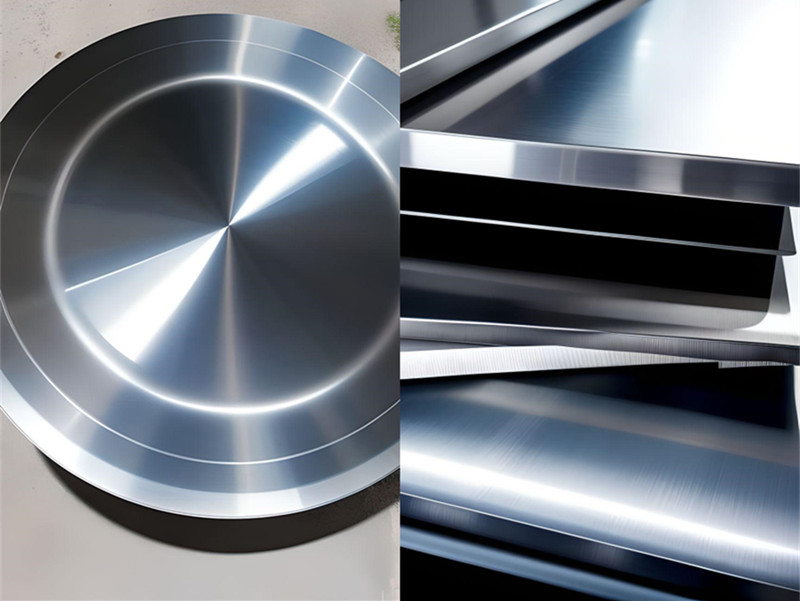

Selection Guide for Titanium and Stainless Steel: How to Choose the Right Material

In industries such as manufacturing, medical devices, and aerospace, material selection directly impacts product performance, lifespan, and application effectiveness. However, each material has its own advantages and limitations, making the decision process challenging for buyers. How can one balance weight reduction with strength? How should cost and performance be weighed against each other? Which material can ensure long-term stability in complex environments? Titanium and stainless steel are two commonly used high-performance metals, each with unique strengths and application scenarios. This article compares them in terms of material properties and typical applications to help buyers make informed decisions based on their product requirements.

1. Comparison of Material Properties

1.1 Titanium (Ti)

Titanium is a lightweight yet high-strength metal known for its exceptional properties, making it a preferred choice in high-end applications:

Lightweight and High Strength: With a density of approximately 4.5 g/cm³, titanium is about 40% lighter than stainless steel while offering comparable or even greater strength. This makes it highly advantageous in applications that require both weight reduction and structural integrity.

Excellent Corrosion Resistance: Titanium exhibits outstanding resistance to corrosion in seawater, chlorine, and acidic environments, making it ideal for harsh conditions such as chemical processing and marine engineering.

Biocompatibility: Titanium is non-toxic and highly compatible with human tissues, preventing rejection reactions. This makes it widely used in medical implants such as artificial joints and dental implants.

High-Temperature Resistance: With a melting point of 1668°C, titanium maintains its mechanical properties even at high temperatures, making it suitable for extreme heat applications.

Difficult to Process: Titanium is challenging to machine and form, requiring specialized equipment and techniques, which can limit its widespread adoption.

1.2 Stainless Steel (SS)

Stainless steel is an iron-based alloy containing chromium, nickel, and other elements, with the following characteristics:

High Strength and Hardness: With a density of approximately 7.9 g/cm³, stainless steel is heavier than titanium but offers superior strength and hardness, making it suitable for high-load applications.

Good Corrosion Resistance: The chromium content in stainless steel forms a dense chromium oxide layer, preventing further corrosion. However, in highly acidic or alkaline environments, stainless steel is less corrosion-resistant than titanium.

Limited Biocompatibility: Some stainless steels, such as medical-grade 316L stainless steel, exhibit good biocompatibility and are used in surgical instruments and medical devices. However, titanium remains the preferred choice for implants.

Heat Resistance: Stainless steel remains stable at high temperatures but does not perform as well as titanium in extreme heat conditions.

Ease of Processing: Stainless steel is relatively easy to machine, weld, and form using conventional manufacturing techniques, making it ideal for mass production.

2. Comparison of Typical Applications

2.1 Typical Applications of Titanium

Aerospace: Titanium’s lightweight and high-strength properties make it widely used in aircraft engines, fuselage structures, and rocket components, reducing overall weight and improving fuel efficiency.

Medical Devices: Due to its excellent biocompatibility, titanium is the material of choice for artificial joints, dental implants, and heart stents.

Chemical Processing Equipment: Titanium’s corrosion resistance makes it suitable for chemical reactors, heat exchangers, and piping systems.

Sports Equipment: Titanium’s strength and low weight make it ideal for high-end sports equipment such as golf clubs and bicycle frames.

2.2 Typical Applications of Stainless Steel

Architecture and Decoration: Stainless steel’s aesthetic appeal, corrosion resistance, and ease of cleaning make it widely used in structural applications, exterior cladding, and railings.

Kitchenware and Household Appliances: Stainless steel is a popular choice for kitchen tools, cookware, sinks, and appliances.

Medical Instruments: Stainless steel (such as 316L) is commonly used for surgical instruments and medical equipment.

Automotive Industry: Stainless steel is used in exhaust systems, structural components, and other automotive parts, where it withstands high temperatures and corrosive environments.

3. How to Choose the Right Material Based on Product Requirements

3.1 When to Choose Titanium

Lightweight and High Strength Needed: Titanium is ideal for aerospace, sports, and other applications requiring a strong yet lightweight material.

High Corrosion Resistance Required: Titanium is the best choice for chemical, marine, and other environments with extreme corrosion risks.

Biocompatibility Is a Priority: In medical applications, titanium is the preferred material for implants due to its excellent compatibility with human tissues.

High-Temperature Applications: Titanium maintains its mechanical properties at high temperatures, making it suitable for extreme heat environments.

3.2 When to Choose Stainless Steel

High Strength and Hardness Required: Stainless steel is widely used in construction, automotive, and industrial applications where strength and durability are key.

Moderate Corrosion Resistance Needed: In most environments, stainless steel provides sufficient corrosion resistance at a more affordable price than titanium.

Ease of Processing and Mass Production: Stainless steel is easier to machine and form, making it suitable for large-scale manufacturing and cost-effective production.

Aesthetic and Durability Considerations: Stainless steel is a popular choice for architectural, decorative, and household applications due to its sleek appearance and durability.

4. Conclusion

Titanium and stainless steel each offer distinct advantages and are suitable for different applications. Titanium’s lightweight, high strength, corrosion resistance, and biocompatibility make it the preferred material for high-end applications, although its processing difficulty limits its widespread use. On the other hand, stainless steel’s affordability, good corrosion resistance, and ease of fabrication make it a mainstream material in industrial and everyday applications.

When selecting a material, buyers should consider:

Performance Requirements: Choose the material that best meets the specific application’s strength, weight, and durability needs.

Manufacturing and Processing Needs: Consider machining complexity and production feasibility when selecting the material.

Operating Environment: Evaluate environmental factors such as corrosion risk and temperature conditions to ensure long-term reliability.

By understanding the key differences between titanium and stainless steel, buyers can make well-informed decisions tailored to their product’s needs. Whether the goal is maximum performance or a balance between practicality and cost-effectiveness, both materials provide reliable solutions for diverse industries.