What are the Ti 3Al 2.5V Titanium Alloy Properties?

1. Composition of Ti-3Al-2.5V Titanium Alloy

The Ti-3Al-2.5V titanium alloy primarily consists of titanium (Ti), aluminum (Al), and vanadium (V):

Titanium: As the base element, comprising over 90% of the alloy, titanium imparts high strength, low density, and excellent corrosion resistance.

Aluminum: At 3%, aluminum forms a strengthening phase, significantly enhancing strength and high-temperature performance.

Vanadium: At 2.5%, vanadium acts as a β-stabilizing element, improving the alloy's ductility and toughness.

2. Effects of Elements on Alloy Properties

1. Role of Aluminum

Aluminum plays a critical role in strengthening the alloy.

Benefits:

Stabilizes the α-phase structure.

Enhances high-temperature strength and oxidation resistance.

Improves machinability and surface hardness.

Considerations:

Excess aluminum content may decrease toughness and increase brittleness, necessitating precise control to maintain a balance between strength and ductility.

2. Role of Vanadium

Vanadium serves as a β-phase stabilizer.

Benefits:

Expands the β-phase temperature range, ensuring good ductility and machinability over a broad temperature range.

Improves corrosion resistance, particularly in chloride environments.

Considerations:

Excess vanadium may lead to coarse grains at high temperatures, negatively impacting mechanical properties and fatigue strength.

3. Phase Structure and Properties

The phase structure of Ti-3Al-2.5V titanium alloy comprises α-phase, β-phase, and a mixture of α+β phases:

α-Phase:

Hexagonal close-packed (HCP) structure.

Provides high strength and excellent corrosion resistance.

β-Phase:

Body-centered cubic (BCC) structure.

Offers superior ductility and plasticity.

By adjusting the aluminum and vanadium content and employing appropriate heat treatment processes, the α-β phase ratio can be optimized to enhance the alloy's overall performance.

4. Application Prospects of Ti-3Al-2.5V Titanium Alloy

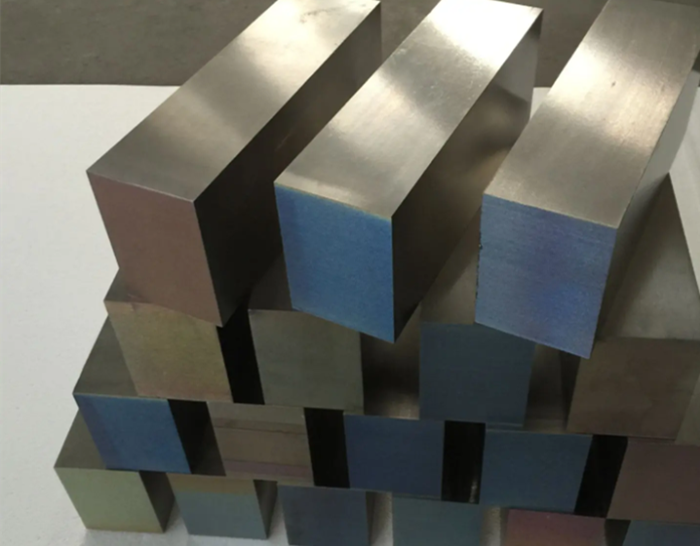

Due to its exceptional strength, toughness, and corrosion resistance, Ti-3Al-2.5V titanium alloy has broad applications across various industries:

Aerospace:

Widely used as a structural material for aircraft fuselages and engine components.

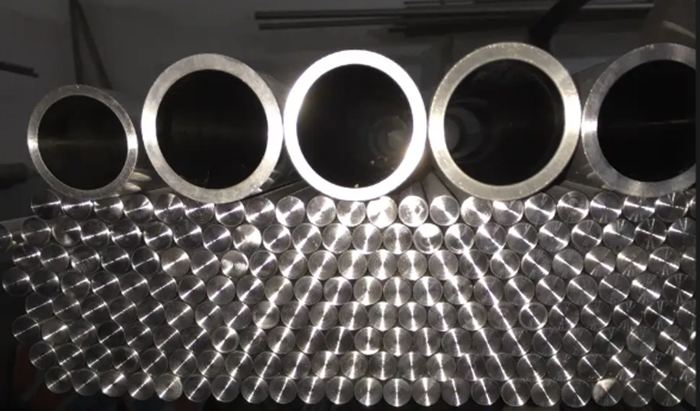

Chemical Processing:

Ideal for corrosion-resistant equipment and piping due to its resistance to harsh environments.

Medical Field:

Owing to its excellent biocompatibility, it is commonly used in implants and surgical instruments.

Ti-3Al-2.5V titanium alloy stands out as a critical material in modern engineering due to its unique chemical composition and outstanding properties. With advancements in technology and machining processes, its application areas are expected to expand further.

Future research focusing on optimizing alloy composition and developing innovative heat treatment techniques will likely enhance its performance to meet the demands of more challenging engineering applications. The continued exploration and development of Ti-3Al-2.5V titanium alloy will significantly contribute to technological progress and innovation across industries.