Which Aluminum Alloy Is Best for Brazing Heat Exchangers

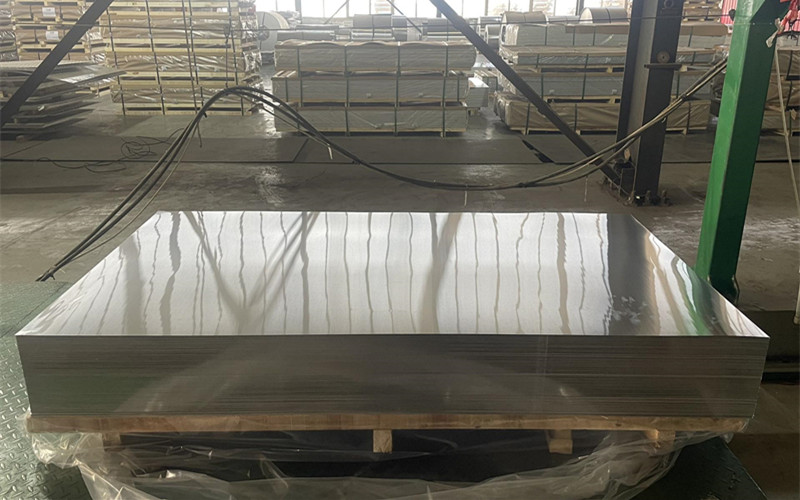

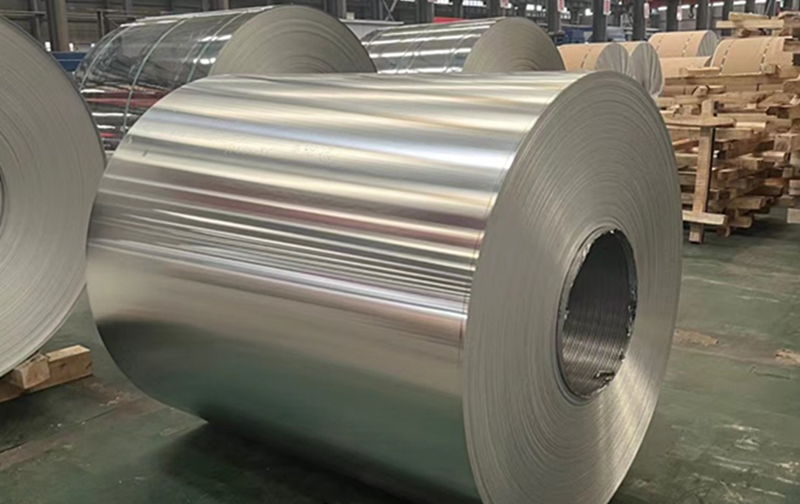

In the field of heat exchanger manufacturing, Aluminum Alloy 4343/3003 Brazing Weld Sheet & Coil is one of the most widely used materials, primarily applied in automotive radiators, condensers, evaporators, and industrial heat exchange equipment. This material consists of a 4343 aluminum alloy cladding layer and a 3003 aluminum alloy base, offering excellent thermal conductivity, corrosion resistance, and outstanding welding performance, making it ideal for high-efficiency heat exchange systems.

When purchasing aluminum brazing sheets, buyers often consider the following key questions:

How can I extend the service life of heat exchange equipment?

How can I reduce production costs while improving brazing quality?

Which type of brazing aluminum sheet is best suited for my application?

This article will explore these questions in depth, providing valuable insights and solutions to help buyers and engineers make informed material selection decisions.

Key Application Areas of 4343/3003 Brazing Aluminum Sheet & Common Questions

1. Automotive Industry: How Can Radiator and Condenser Durability Be Improved?

Cooling systems, air conditioning systems, and exhaust gas recirculation systems in vehicles rely on efficient heat exchangers to function properly. The choice of materials plays a crucial role in determining the durability and performance of these components. To ensure long-term stability, radiators and condensers must be made from materials with excellent thermal conductivity, corrosion resistance, and welding properties.

-- Why do traditional radiator materials corrode easily?

Due to constant exposure to coolant and air, standard aluminum alloys are prone to corrosion, leading to heat exchanger failure. The 4343/3003 brazing aluminum sheet features a 4343 aluminum cladding layer with high silicon content, forming a protective barrier that significantly reduces pitting and oxidation risks, thereby extending product lifespan.

--Why do welded heat exchangers develop cracks?

During welding, aluminum materials expand and contract with temperature changes, which can create cracks. The 4343 aluminum layer has a low melting point, allowing it to fill gaps evenly during brazing, resulting in a more compact and fatigue-resistant weld joint, reducing the risk of cracks.

--How can production costs for heat exchangers be reduced?

Compared to copper radiators, aluminum heat exchangers are more cost-effective and lightweight. Using 4343/3003 aluminum brazing sheets improves processing efficiency while minimizing material waste, reducing manufacturing costs by 15-30%.

2. Industrial Heat Exchange Equipment: How to Ensure Stability Under High-Temperature Conditions?

In industries such as petrochemicals, power generation, and refrigeration, heat exchangers must operate under high temperatures and pressures for extended periods. To maintain stable performance in harsh environments, these systems require materials with excellent thermal conductivity, oxidation resistance, and structural integrity. Choosing the right brazing aluminum alloy helps enhance durability and efficiency, reducing the risk of corrosion and mechanical failure.

--Why do heat exchange tubes fail due to high-temperature oxidation?

Under high-temperature conditions, metal surfaces can form oxidation layers, reducing heat transfer efficiency. The 4343/3003 aluminum brazing sheet's 4343 aluminum alloy minimizes oxidation risks and forms a stable protective layer, ensuring long-term performance in high-temperature environments.

-- How can heat exchanger efficiency be maintained despite scaling?

Over time, industrial heat exchangers may experience scaling buildup on internal surfaces, reducing heat transfer efficiency. The high thermal conductivity of 4343/3003 aluminum sheets ensures a more uniform surface temperature, reducing scale buildup and maintaining optimal heat exchange performance.

-- How can maintenance costs be lowered while extending equipment lifespan?

Traditional heat exchangers require frequent and costly maintenance, especially in chemical and energy industries. Using 4343/3003 aluminum brazing sheets reduces corrosion and oxidation-related failures, minimizing downtime and extending equipment lifespan, thereby lowering overall operating costs.

3. Home Appliance Industry: How to Optimize the Energy Efficiency of Air Conditioning and Refrigeration Systems?

When designing air conditioners, refrigerators, and commercial cooling units, manufacturers need to enhance efficiency while reducing product weight. This can be achieved by selecting lightweight materials with high thermal conductivity, such as aluminum brazing sheets. Using advanced aluminum alloys helps improve heat exchange performance, lower energy consumption, and optimize overall system design.

-- Why do traditional copper heat exchangers struggle to meet lightweight requirements?

Copper has excellent thermal conductivity but is significantly heavier than aluminum, making it unsuitable for modern lightweight appliance designs. The 4343/3003 brazing aluminum sheet is over 50% lighter than copper while maintaining excellent heat transfer capabilities, reducing overall system weight and improving energy efficiency.

-- How can home appliance heat exchangers improve cooling performance?

The heat exchanger’s thermal conductivity directly affects the cooling efficiency of air conditioners and refrigerators. The 4343/3003 aluminum sheet’s superior thermal conductivity facilitates faster heat dissipation, enhancing evaporator and condenser performance while lowering energy consumption.

-- How can product lifespan be extended?

Consumers expect home appliances to be durable, and the corrosion resistance of heat exchangers plays a crucial role. The 3003 aluminum base material has excellent corrosion resistance, ensuring stable performance even in humid environments and reducing the frequency of repairs and maintenance.

Why Choose Us as Your Aluminum Alloy Supplier?

If you are looking for a high-quality Aluminum Alloy 4343/3003 Brazing Weld Sheet & Coil supplier, we are your ideal partner.

Choose Shenzhen Chinalcometal:

--Customizable Specifications – We offer a wide range of thicknesses, widths, and alloy combinations tailored to your needs.

--Strict Quality Control – Our advanced manufacturing processes ensure stable alloy composition and excellent brazing performance.

--Sufficient Inventory & Fast Delivery – We maintain stock availability to shorten lead times and enhance production efficiency.

--Professional Technical Support – We provide expert advice on material selection and welding techniques to ensure the best results for your products.

Contact us today for a competitive quote on high-quality brazing aluminum sheets! Our team is ready to assist you with professional consultation and premium materials, helping you achieve superior heat exchange performance.