Aluminum Flat Bar For Aerospace 2014 7050

Aerospace aluminum bars

Aluminum flat bars are used in the aviation industry, with major grades including 2014, 2014A, 7050, and 2219. These aluminum bars possess excellent mechanical properties and corrosion resistance, meeting the stringent requirements of aerospace applications.

The primary characteristics of 2014 and 2014A aluminum bars are high strength and good machinability. They contain copper and silicon, making them suitable for high-load structural components such as aircraft frames, wing beams, and skins. 2014A is an improved version of 2014, offering better corrosion resistance.

7050 aluminum bars exhibit extremely high strength and excellent corrosion resistance, particularly in stress corrosion environments. They are widely used in critical aircraft structural components such as wing beams, fuselage frames, and landing gear.

7050 aluminum bars remain stable under high pressure and stress, extending the service life of aircraft.

2219 aluminum bars have excellent mechanical properties and good heat resistance, making them suitable for aircraft engine parts and structural components used in high-temperature environments. Their high strength and heat resistance ensure the reliable operation of aerospace engines.

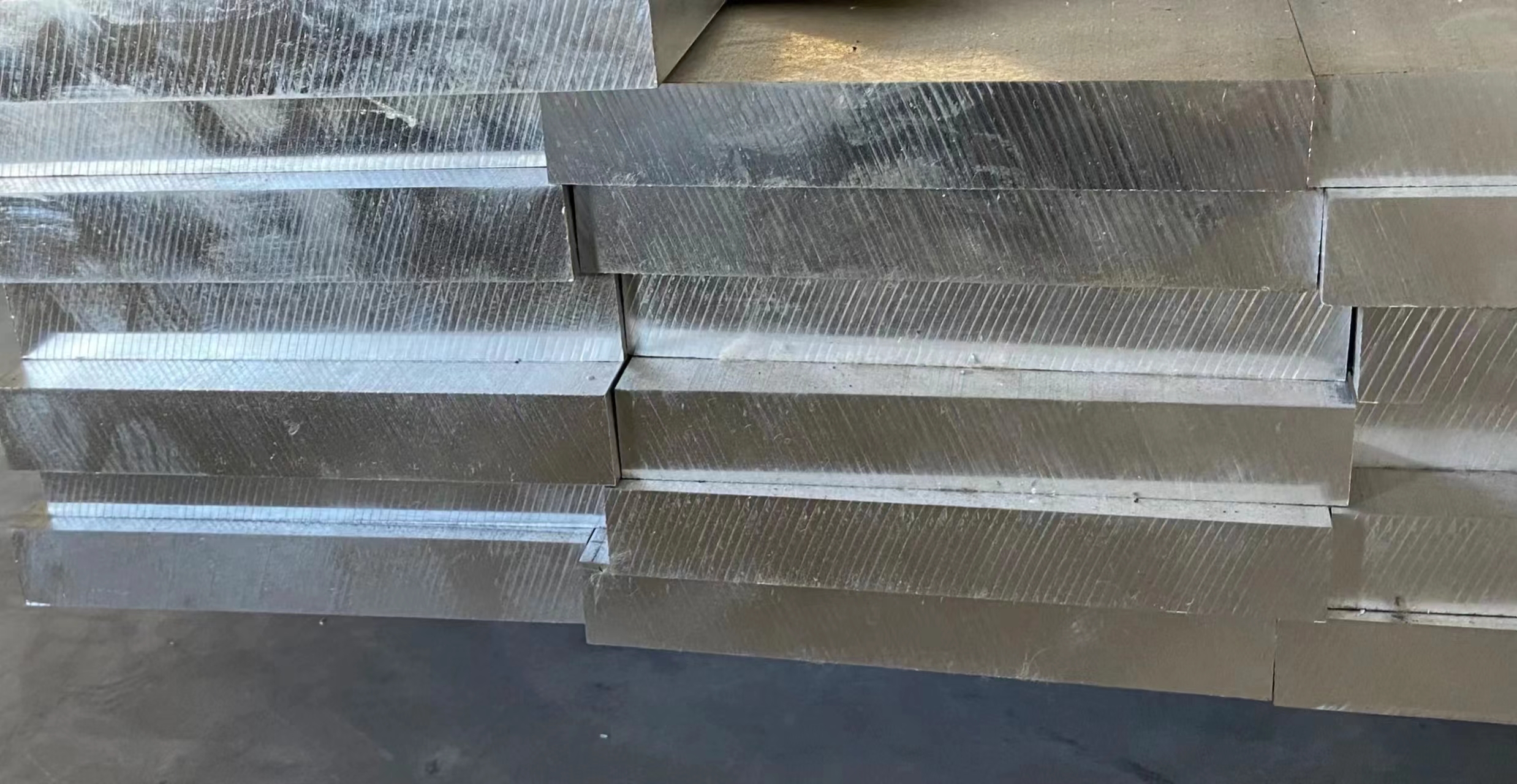

Aerospace aluminum bars are typically precision-machined to meet the needs of various components. Common size ranges include widths from 10mm to 300mm and thicknesses from 5mm to 100mm. Custom sizes are available based on specific applications.

These high-performance aluminum bars have a wide range of applications in the aviation industry. They are used to manufacture structural components, wings, fuselages, and engine parts. The lightweight and high-strength characteristics of aluminum bars improve fuel efficiency and payload capacity, ensuring flight safety and economy.