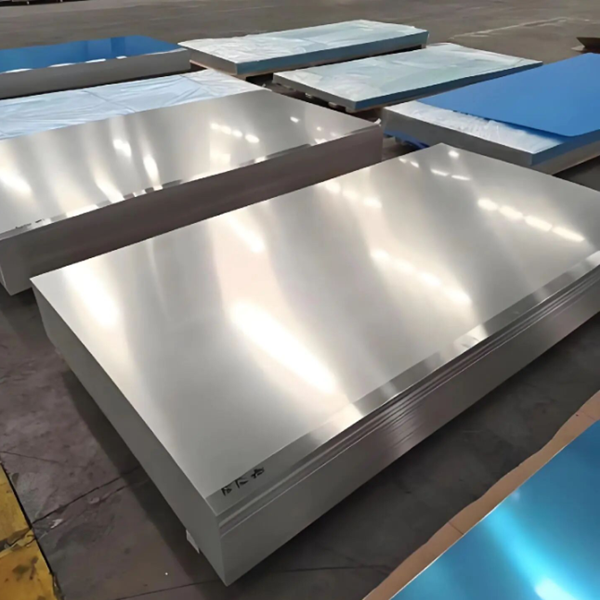

Aluminum Tread Plate Sheet Coil Alloy 1100 1060 3003 5052 5754 5083 6061 6082

- Description

What is aluminum tread plate?

Aluminum tread plate is a lightweight, durable metal sheet featuring raised patterns that enhance grip and visual appeal. Commonly known as aluminum diamond tread plate, 5 bar aluminum tread plate, or embossed aluminum tread plate, it’s widely used in flooring, trailer walls, toolboxes, fenders, stair treads, and more. We offer a full range of aluminum tread plate types and sizes, including aluminum tread plate sheet 4x8, 1/8 aluminum tread plate, and aluminum tread plate for sale in various finishes like bright aluminum tread plate and black aluminum tread plate.

Our aluminum tread plates are available in popular alloys to meet different application needs. The 3003 H22 aluminum tread plate and 4017 aluminum tread plate offer good strength and corrosion resistance, making them ideal for general flooring, toolboxes, and RV panels. For heavy-duty or marine environments, we provide 5052, 5754, and 5083 five bar aluminum tread plate, known for their high strength and saltwater resistance. For structural or high-stress use, our 6061 aluminum tread plate combines durability with machinability.

Aluminum Tread Plate Sheet Common Alloys and Sizes

Alloy | Size(mm) | Common Use |

3003 3004 3104 | Thickness:1.5-3.0mm Width:100-1500mm Length:1000-6000mm or coil | General purpose, decorative, indoor flooring |

5052 | Thickness:1.5-5.0mm Width:100-1500mm Length:1000-6000mm or coil | Marine, transport, outdoor, high-traffic areas |

5754 5083 | Thickness:1.5-6.0mm Width:100-1500mm Length:1000-6000mm or coil | Marine decks, ramps, trailers (EU preferred) |

6061 6063 6082 | Thickness:1.5-6.0mm Width:100-1500mm Length:1000-6000mm or coil | Heavy-duty flooring, structural applications |

1050 1060 1100 | Thickness:1.0-3.0mm Width:100-1500mm Length:1000-6000mm or coil | Decorative, light-duty, cladding panels |

Aluminum Tread Plate Sheet Patterns of

Pattern Type | Description |

Five Bar/5-bars | Most common; high anti-slip grip |

Diamond / One Bar | Also common in US market |

Two-Bar / Three-Bar Pattern | Contains two or three parallel raised bars instead of five |

Tear Drop / Lentil | For decorative or vehicle use |

Orange Peel | Lightweight, often decorative |

Applications of Aluminum Tread Plate Sheets and Coils

1. Marine Industry

5 bar aluminum tread plate and diamond tread aluminum plate are commonly used for ship decks, docks, and gangways. Their anti-slip surface and corrosion resistance make them ideal for harsh marine environments.

2. Automotive & Transportation

Aluminum tread plate for trailer flooring, truck beds, toolboxes, and ramps adds durability and grip. 6061 aluminum tread plate is often used in high-strength vehicle parts and steps.

3. Construction & Architecture

Used for stair treads, elevator floors, wall panels, and decorative cladding. Bright aluminum tread plate offers both style and function for modern building design.

4. Industrial & Manufacturing

Perfect for work platforms, warehouse floors, and machine covers. 3003 H22 aluminum tread plate is favored for its balance of strength and formability.

5. Household & Commercial Use

Applied in kitchen backsplashes, cold storage truck floors, and non-slip public walkways. Black aluminum tread plate adds a sleek look to utility spaces.

6. Aerospace & Defense

Lightweight yet strong, aluminum tread brite diamond plate and 6061 T6 tread plate are used for aircraft flooring, military vehicle panels, and cargo bay linings.