EN AW 5083 Cast Aluminum Mold Plate

What Is EN AW 5083 Cast Aluminum Plate?

EN AW 5083 is a cast aluminum plate from the 5000 series. It is based on an aluminum-magnesium alloy. Compared to other 5000 series cast plates like 5052 or 5754, 5083 offers higher strength and better corrosion resistance, especially in marine environments. That makes it ideal for heavy-duty parts and mold bases.

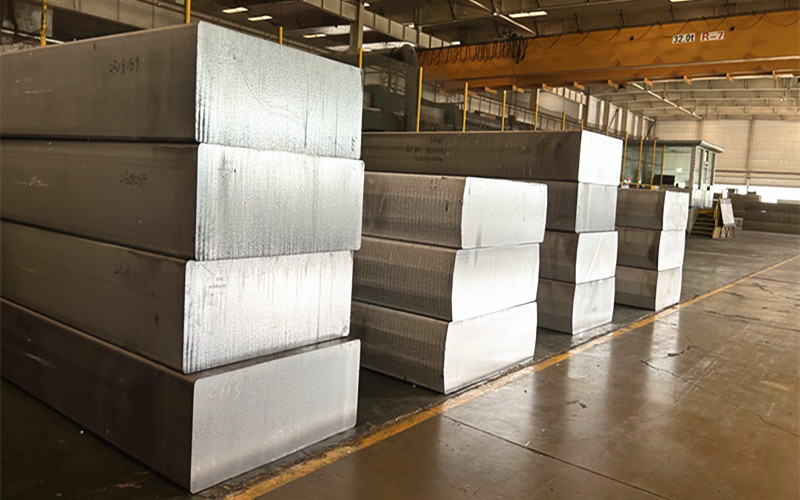

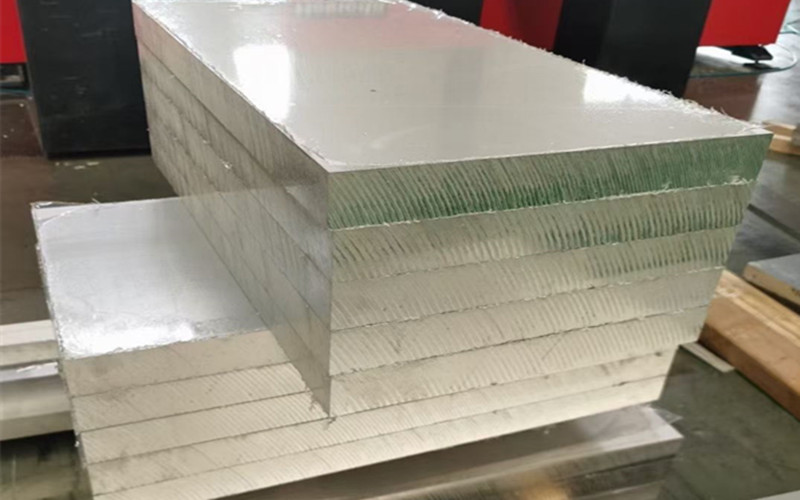

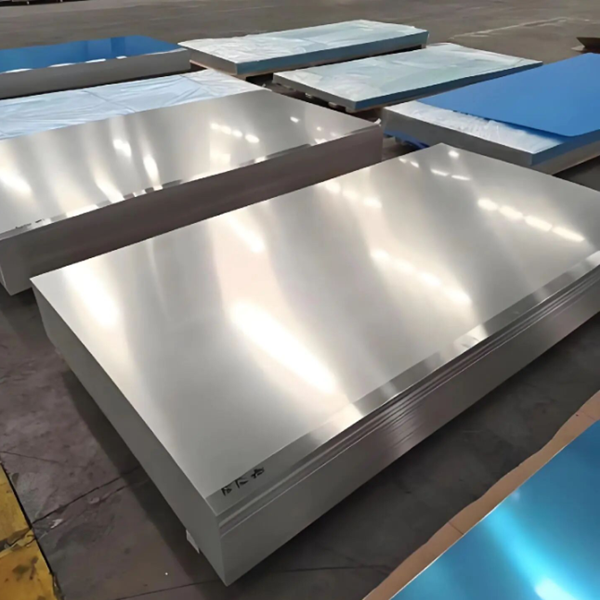

Cast 5083 plates are often used where flatness and thickness are critical. They are machined from cast aluminum blocks, not rolled. This gives them good dimensional stability and reduced internal stress. EN AW 5083 is a popular choice for shipbuilding, tooling, and structural applications.

EN AW 5083 Chemical Composition and Properties

| Element | Content |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9% |

| Manganese (Mn) | 0.4 – 1.0% |

| Chromium (Cr) | 0.05 – 0.25% |

| Iron (Fe) | ≤ 0.4% |

| Silicon (Si) | ≤ 0.4% |

| Zinc (Zn) | ≤ 0.25% |

| Copper (Cu) | ≤ 0.1% |

| Aluminum (Al) | Balance |

| Property | Value |

|---|---|

| Density | 2.66 g/cm³ |

| Yield Strength | ≥ 215 MPa |

| Tensile Strength | ≥ 290 MPa |

| Hardness | 65–75 Brinell |

| Elongation | ≥ 12% |

| Corrosion Resistance | Excellent |

| Weldability | Excellent |

EN AW 5083 aluminum plate size

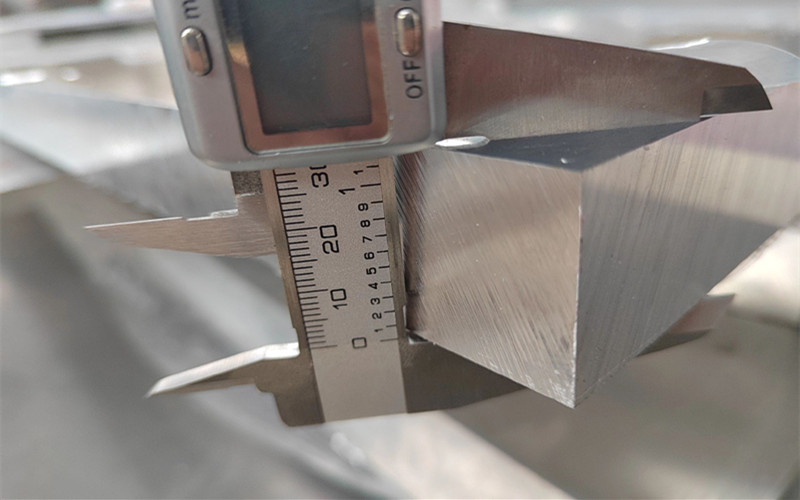

Name | Thickness | Tolerance of Thickness | Width | Length |

EN AW 5083 | 5mm-600mm | -1.0mm---+1.0mm | 30mm-2000mm | 50mm-5000mm

|

5083 Stock | 5, 10, 20, 25, 30, 35,40,50,60,70,80, 100,120,150,200, 220,260,300,350, 400,450,500,550 | -1mm-----+1mm | 1250mm*2500mm 1500mm*3000mm 1520mm*3050mm 1650mm*3660mm | |

EN AW 5083 vs MIC-6 Aluminum Plate vs K100S Aluminum Plate

1. Composition Comparison

| Material | Main Composition (%) | Alloy Series | Process |

|---|---|---|---|

| EN AW 5083 | Al + 4-4.9% Mg + 0.4-1% Mn | 5000 Series (Al-Mg) | Rolled Plate |

| MIC-6 | Al + 11-13% Si + trace Fe/Cu | Cast Al-Si Alloy | Cast + Precision Milling |

| K100S | Al + 3-4% Mg + trace Mn/Cr (similar to 5754) | 5000 Series (Al-Mg) | Rolled/Special Treatment |

2. Properties Comparison

| Property | EN AW 5083 | MIC-6 | K100S |

|---|---|---|---|

| Strength | Medium (Tensile ~270-320 MPa) | Low (cast alloy, non-heat treatable) | Medium (similar to 5754, ~200-250 MPa) |

| Corrosion Resistance | Excellent (especially seawater) | Fair (Si prone to oxidation) | Good (resists chemical corrosion) |

| Thermal Stability | Poor (high thermal expansion) | Excellent (low expansion, stress-free) | Moderate |

| Machinability | Weldable, easy to form | High-precision machining (avoid high heat) | Weldable, easy to stamp |

| Surface Quality | Requires post-treatment | Mirror-like (directly milled) | High flatness |

3. Typical Applications

| Material | Applications |

|---|---|

| EN AW 5083 | Shipbuilding, marine platforms, chemical tanks (corrosion resistance + weldability) |

| MIC-6 | Semiconductor equipment bases, optical platforms, vacuum chambers (zero distortion + high stability) |

| K100S | Medical devices, food machinery, transportation (balances corrosion resistance and machinability) |

4. Alternative Materials

| Material | Substitutes (Similar Properties) | Reason for Substitution |

|---|---|---|

| EN AW 5083 | 5052 (AlMg2.5) | Lower strength but easier to form, suitable for lightweight needs |

| MIC-6 | AlSi10Mg (for 3D printing) or A383 (AlSi12) | Both are cast Al-Si alloys with similar stability |

| K100S | EN AW 5754 (AlMg3) | Nearly identical composition and properties, internationally standardized |

FAQ about 5083 aluminum plate:

1. How is 5083 cast aluminum plate made?

It is made by casting aluminum ingots, then cutting and milling them to size. The plate is stress-relieved to improve stability.

2. Can you bend 5083 aluminum?

Yes. 5083 has good formability. But it must be done carefully, especially in thick sections.

3. What is 5083 aluminum used for?

It is used in shipbuilding, mold bases, pressure vessels, and heavy-duty parts.

4. Is 5083 aluminum a specialty metal?

No. It is a standard industrial-grade aluminum alloy, widely used in many industries.

5. What are the different tempers of 5083 aluminum plate?

5083-O – Annealed, soft, easy to form

5083-H111 – Slightly strain-hardened, used for marine parts

5083-H112 – As fabricated, for thick plate applications

5083-H116 – Special temper for excellent corrosion resistance in marine environments

5083-H32 – Hardened and partially annealed, offers good strength and formability