Marine Aluminum plate and sheet Alloy 5086 5754 5052 5083 5383 5456

Marine-grade aluminum plate is a high-performance aluminum alloy material specifically designed to withstand harsh marine environments. It primarily utilizes 5-series aluminum-magnesium alloys (such as 5083, 5086, 5754, 5052, 5383, and 5456), incorporating 3%-5% magnesium along with trace amounts of manganese and chromium to form a dense oxide film. This protective layer enables the material to effectively resist pitting, intergranular corrosion, and stress corrosion, even when exposed to prolonged seawater immersion or salt spray, extending its lifespan to more than three times that of ordinary aluminum plates.

Additionally, its specialized processing techniques (such as H116 temper heat treatment) further stabilize the internal structure, ensuring that welded joints maintain the same corrosion resistance as the base material, thereby eliminating the risk of corrosion-induced fractures common in standard aluminum plates.

These aluminum plates also offer a balanced combination of moderate strength (with tensile strength ranging from approximately 275-350 MPa) and lightweight properties (with a density only one-third that of steel). This allows them to support heavy structures like ships and offshore platforms while significantly reducing overall weight.

Certified by international classification societies (CCS, DNV, GL, ABS, BV, and LR), marine-grade aluminum plates require no additional anti-corrosion coatings and can be directly exposed to marine environments, making them essential materials for shipbuilding, seawater pipelines, and marine engineering.

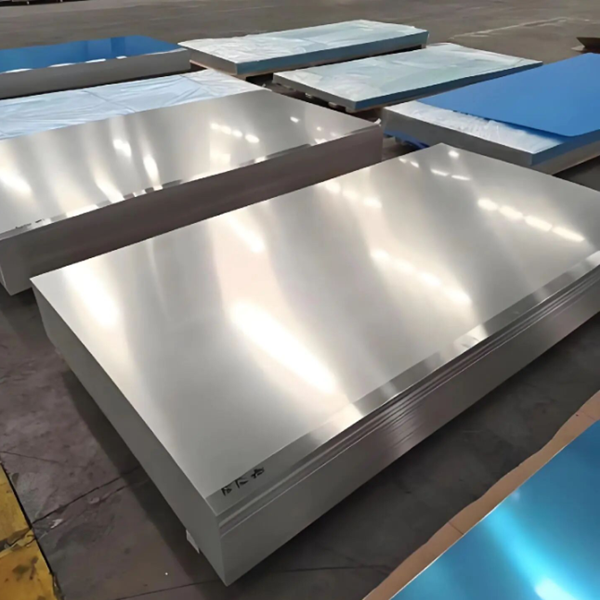

Sizes of the marine grade aluminum plate/sheet

Product | Thickness(mm) | Width(mm) | Length(mm) |

Aluminum Plate | 6mm--260mm | 800mm--4300mm | 1000mm--38000mm |

Aluminum Sheet | 2.0mm-6mm | 1000mm--2800mm | 1000mm--12000mm |

Comprehensive Guide to Marine-Grade Aluminum Alloys: 5086, 5754, 5052, 5083, 5383, 5456

Marine-grade aluminum is a vital material in the shipbuilding industry, offshore structures, and boat manufacturing, thanks to its exceptional corrosion resistance, strength, and weldability. Below is a detailed breakdown of the most commonly used marine aluminum alloys and their properties, applications, and benefits.

1. 5086 Marine-Grade Aluminum (O/H116)

Applications:

Widely used in shipbuilding, yachts, offshore platforms, and other marine structures requiring high-strength corrosion-resistant aluminum.

Key Properties:

O Temper (Annealed): Fully softened for maximum workability.

H116 Temper: High-strength alloy with excellent seawater corrosion resistance, ideal for hulls and structural components.

Benefits:

Superior saltwater corrosion resistance.

Excellent weldability, essential for marine construction.

2. 5754 Marine-Grade Aluminum (H112)

Applications:

Commonly used in boat hulls, bulkheads, decks, and marine structural components where moderate strength and high corrosion resistance are required.

Key Properties:

H112 Temper: Strain-hardened to balance strength and formability.

Benefits:

Great corrosion resistance in marine environments.

Ideal for medium-duty applications requiring a balance of strength and workability.

3. 5052 Marine-Grade Aluminum (H32/O)

Applications:

Used in boat decks, fuel tanks, marine panels, and industrial equipment requiring high durability and corrosion resistance.

Key Properties:

O Temper (Annealed): Soft and highly workable, allowing for complex shaping.

H32 Temper: Strain-hardened for increased strength while maintaining good formability.

Benefits:

Outstanding saltwater resistance.

Excellent for marine environments where moderate strength and high corrosion resistance are needed.

4. 5083 Marine-Grade Aluminum (H321/H116/H112/O)

Applications:

One of the most commonly used marine alloys for ship hulls, boat structures, offshore equipment, and defense applications.

Key Properties:

H321 Temper: Provides high strength and superior corrosion resistance.

H116 Temper: High-strength, corrosion-resistant aluminum for critical structural components like boat hulls.

H112 Temper: General-purpose alloy offering a balance between strength and formability.

O Temper (Annealed): Ideal for fabrication requiring easy forming.

Benefits:

Exceptional corrosion resistance in seawater environments.

High welding strength, making it ideal for marine engineering.

5. 5383 Marine-Grade Aluminum (H321/H116)

Applications:

Designed for high-performance marine applications, including offshore structures, boat hulls, and fishing vessels.

Key Properties:

H321/H116 Tempers: Provide superior strength and seawater corrosion resistance.

Benefits:

Higher strength compared to 5086 aluminum.

Long-lasting performance in saltwater environments.

6. 5456 Marine-Grade Aluminum (H321/H116)

Applications:

Used in large marine vessels, offshore platforms, and structural components exposed to seawater.

Key Properties:

H321/H116 Tempers: Deliver exceptional strength, corrosion resistance, and fatigue resistance.

Benefits:

Ideal for marine construction requiring high strength and durability.

Excellent weldability, ensuring structural integrity in harsh marine conditions.

As a trusted supplier of marine-grade aluminum, we are committed to providing high-quality materials that meet the rigorous demands of marine environments. If you are looking for marine-grade aluminum prices, feel free to contact us directly. Our team will provide you with competitive quotes and tailored solutions to meet your specific needs. Whether for shipbuilding, offshore platforms, or marine engineering projects, we are here to support you with the best materials and expert guidance. Reach out Shenzhen Chinalcometal today for more information!