Extruded 6061 Aluminum bar T6 T4 T651

Shenzhen Chinalco Metal supply extruded 6061 aluminum bars in a variety of shapes—including flat, round, and hexagon—and tempers such as T6, T651, and T4. Known as one of the most versatile and widely used aluminum alloys, 6061 offers an excellent balance of strength, corrosion resistance, and machinability, making it a go-to material across many industries. Let's take a closer look at the chemical composition, mechanical properties, and common applications of 6061 extruded aluminum bars to help you find the right fit for your needs.

Chemical composition of 6061 Aluminum Bar

| Element | Content (%) |

|---|---|

| Aluminum (Al) | 95.8 – 98.6 |

| Magnesium (Mg) | 0.8 – 1.2 |

| Silicon (Si) | 0.4 – 0.8 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | 0.15 – 0.4 |

| Chromium (Cr) | 0.04 – 0.35 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others | ≤ 0.15 (total) |

Mechanical Properties of 6061 Aluminum Bars (T6, T651, T4)

| Property | T4 Temper | T6 Temper | T651 Temper |

|---|---|---|---|

| Yield Strength (MPa) | ~145 | ≥ 240 | ≥ 240 |

| Ultimate Tensile Strength | ~240 MPa | ≥ 260 MPa | ≥ 260 MPa |

| Elongation (%) | 10–16% | 8–10% | 8–10% |

| Brinell Hardness | ~60 | 95 | 95 |

| Density (g/cm³) | 2.70 | 2.70 | 2.70 |

| Modulus of Elasticity (GPa) | ~68.9 | ~68.9 | ~68.9 |

T4: Naturally aged after solution heat treatment. Offers good ductility and is easy to form or bend.

T6: Artificially aged after solution heat treatment. Provides maximum strength.

T651: Similar to T6 but stress-relieved by stretching. Ideal for precision machining.

Common Shapes: Flat, Round, and Hexagon

Flat Bar

Widely used in structural frames, supports, and brackets.

Excellent for welding and machining.

Round Bar

Common in shafts, pins, rollers, and aerospace connectors.

Offers consistent strength and machinability.

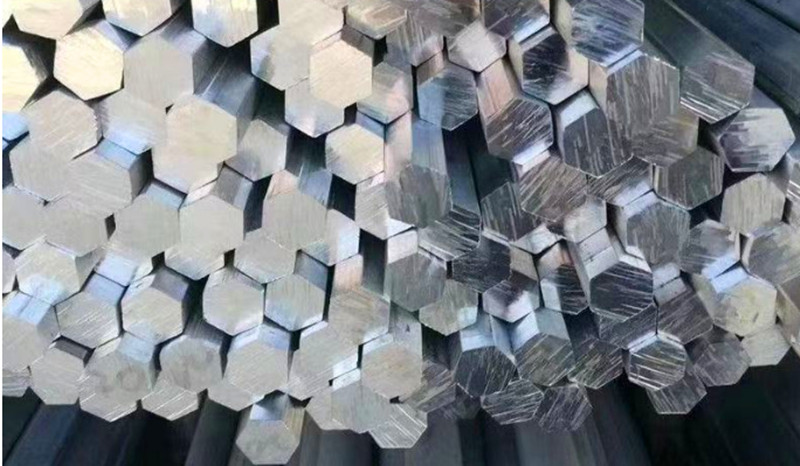

Hexagon Bar

Ideal for fasteners, fittings, and precision-machined components.

The shape improves grip and torque control in mechanical assemblies.

All shapes are available in a variety of dimensions, and the extruded surface ensures good finish quality and tight dimensional tolerances.

Specifications: ASTM B211, AMS 4115, AMS 4116, AMS 4117, AMS 4128, AMS-QQ-A-225/8 & ASTM B221, AMS4150, AMS 4160, AMS 4161, AMS-QQ-A-200/8

6061 t6 aluminum flat bar size

| Alloy | Height(mm) | Width(mm) |

| 6061 flat bar | 2,3,5,6,8,10,12,14,15,16,18, 18.5,20,25,30,35,40,45,50,55, 60,65,70,75,76,80,85,90,100, | 20,25,30,40,50,75,85,95, 100,110,120,130,140,150, 160,170,180,190,200 |

6061 t6 aluminum hexagon bar size

| 6061 hex bar flat to flat distance(mm) | H7,8,9,10,11,12,13,14,15,16,17,18,19,20, 21,22,23,24,25,26,27,28,29,30,32,35,40 |

6061 t6 aluminum round bar stock

Alloy | Temper | Dia.(mm) | Length(mm) |

6061 | T651 | φ5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20 21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36 38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53, 54,55,56,57,58,59,60,62,63,65,68, 70,75,80,85,90,95, 100,105,110,115,120,125,130,135,140,145,150,155, 160,165,170,175,180, | 2500/3000 |

6061 | T6 | φ190,195,200,205,210,215,220,230, 240,250,260,270,280,290, | 2500/3000 |

6061 | T6 | φ300,310,320,330,340 | 2500 |

6061 | H112 | φ350,360,370,380,390,400,410,420,430,440,450,460, 470,480,490,500,510,520,530,540,550,560,570,580, 590,600,610,620 | 2500 |

6061 aluminum bar applicatons:

6061 extruded aluminum bars are widely used across aerospace, automotive, marine, and construction industries thanks to their strength, lightweight nature, and corrosion resistance. In the UAV (drone) industry, 6061 T6 aluminum is especially favored for CNC machining of structural components such as frames, arms, motor mounts, gimbals, and camera brackets, providing excellent dimensional accuracy, vibration resistance, and mechanical durability.

Beyond drones, 6061 bars are extensively used in CNC machining of precision parts across industries—such as robotic joints, mounting plates, optical housings, custom brackets, heat sinks, and fixture components. Its good machinability and consistent mechanical properties make it a top choice for parts that require tight tolerances, surface finish quality, and long-term reliability.