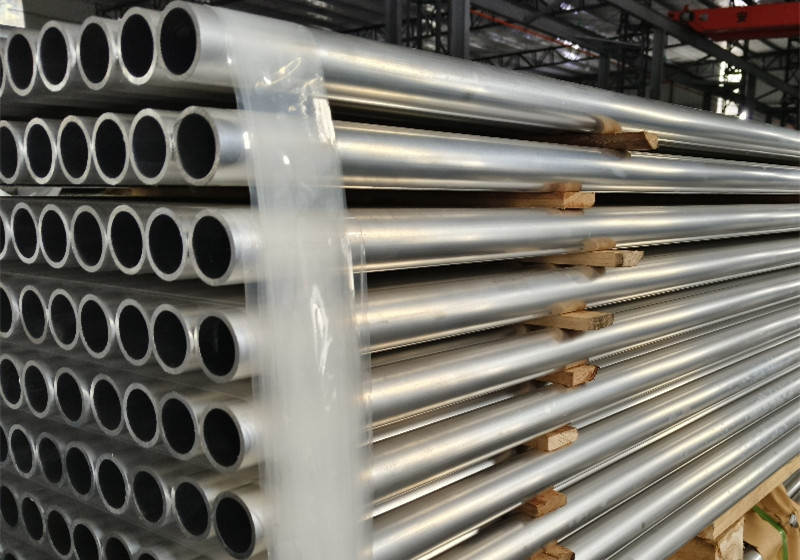

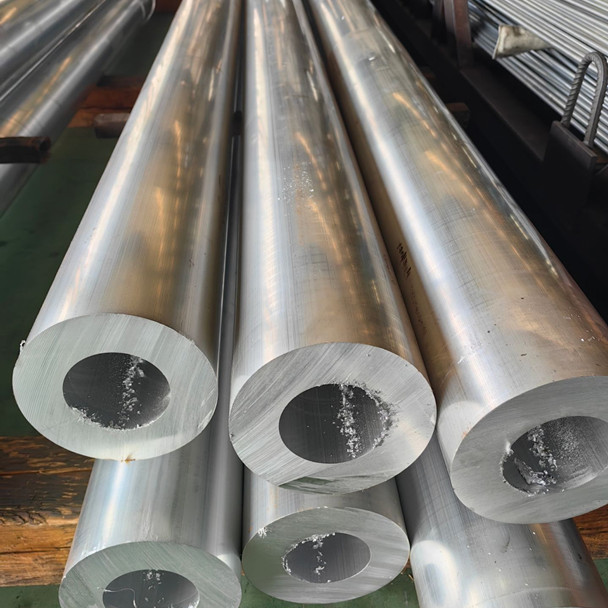

6061 T6 Aluminum extruded seamless pipe

6061 T6 aluminum seamless pipe is an aluminum alloyed with magnesium and silicon, known for its versatility. This all-purpose material offers good corrosion resistance, formability, and medium strength. It features excellent machining properties and achieves an attractive appearance after anodizing.

The 6061-T6 aluminum pipe is extruded, ensuring a seamless structure, making it suitable for both interior and exterior applications. While it performs well with most processing techniques, it is not ideal for bending or forming. Common uses include railings, docks, posts, and hinges. The pipe is lightweight and has a smooth, light grey finish.

Stock list of 6061 T6 Aluminum extruded seamless pipe

OD mm | W.T.mm | Length mm | Material |

40 | 5 | 6020 | 6061T6 |

50 | 5 | 6020 | 6061T6 |

50 | 10 | 6020 | 6061T6 |

50 | 15 | 6020 | 6061T6 |

55 | 5 | 6020 | 6061T6 |

55 | 10 | 6020 | 6061T6 |

55 | 15 | 6020 | 6061T6 |

55 | 20 | 6020 | 6061T6 |

60 | 5 | 6020 | 6061T6 |

60 | 10 | 6020 | 6061T6 |

60 | 15 | 4020 | 6061T6 |

60 | 20 | 6020 | 6061T6 |

65 | 5 | 6020 | 6061T6 |

65 | 10 | 6020 | 6061T6 |

65 | 15 | 4020 | 6061T6 |

65 | 20 | 6020 | 6061T6 |

70 | 5 | 6020 | 6061T6 |

70 | 10 | 6020 | 6061T6 |

70 | 15 | 6020 | 6061T6 |

70 | 20 | 6020 | 6061T6 |

70 | 25 | 6020 | 6061T6 |

75 | 5 | 4020 | 6061T6 |

75 | 10 | 6020 | 6061T6 |

75 | 15 | 6020 | 6061T6 |

75 | 20 | 6020 | 6061T6 |

75 | 25 | 6020 | 6061T6 |

80 | 5 | 6020 | 6061T6 |

80 | 10 | 6020 | 6061T6 |

80 | 15 | 4020 | 6061T6 |

80 | 20 | 5020 | 6061T6 |

80 | 25 | 4500 | 6061T6 |

80 | 30 | 4500 | 6061T6 |

85 | 5 | 4020 | 6061T6 |

85 | 10 | 4020 | 6061T6 |

85 | 15 | 6020 | 6061T6 |

85 | 20 | 5000 | 6061T6 |

85 | 25 | 4000 | 6061T6 |

85 | 30 | 2600 | 6061T6 |

90 | 5 | 6020 | 6061T6 |

90 | 10 | 6020 | 6061T6 |

90 | 15 | 6020 | 6061T6 |

90 | 20 | 4520 | 6061T6 |

90 | 25 | 3520 | 6061T6 |

90 | 30 | 3020 | 6061T6 |

95 | 5 | 6020 | 6061T6 |

95 | 10 | 6020 | 6061T6 |

95 | 15 | 5500 | 6061T6 |

95 | 20 | 6020 | 6061T6 |

95 | 25 | 6020 | 6061T6 |

95 | 30 | 6020 | 6061T6 |

95 | 10 | 6020 | 6061T6 |

100 | 5 | 6020 | 6061T6 |

100 | 10 | 6020 | 6061T6 |

100 | 15 | 6020 | 6061T6 |

100 | 20 | 6020 | 6061T6 |

100 | 25 | 6020 | 6061T6 |

100 | 30 | 6020 | 6061T6 |

100 | 5 | 6020 | 6061T6 |

105 | 10 | 6020 | 6061T6 |

105 | 15 | 6020 | 6061T6 |

105 | 20 | 6020 | 6061T6 |

105 | 25 | 6020 | 6061T6 |

105 | 30 | 6020 | 6061T6 |

110 | 5 | 6020 | 6061T6 |

110 | 10 | 6020 | 6061T6 |

110 | 15 | 4500 | 6061T6 |

110 | 20 | 6020 | 6061T6 |

110 | 25 | 6020 | 6061T6 |

110 | 30 | 6020 | 6061T6 |

115 | 5 | 6020 | 6061T6 |

115 | 10 | 6020 | 6061T6 |

115 | 15 | 6020 | 6061T6 |

115 | 20 | 6020 | 6061T6 |

115 | 25 | 6020 | 6061T6 |

115 | 30 | 6020 | 6061T6 |

120 | 5 | 6020 | 6061T6 |

120 | 10 | 6020 | 6061T6 |

120 | 15 | 6020 | 6061T6 |

120 | 20 | 6020 | 6061T6 |

120 | 25 | 6020 | 6061T6 |

120 | 30 | 6020 | 6061T6 |

120 | 40 | 6010 | 6061T6 |

125 | 10 | 6010 | 6061T6 |

125 | 15 | 6010 | 6061T6 |

125 | 20 | 6010 | 6061T6 |

125 | 25 | 6010 | 6061T6 |

125 | 30 | 6010 | 6061T6 |

130 | 5 | 5020 | 6061T6 |

130 | 10 | 6010 | 6061T6 |

130 | 15 | 6010 | 6061T6 |

130 | 20 | 6010 | 6061T6 |

130 | 25 | 6010 | 6061T6 |

130 | 30 | 6010 | 6061T6 |

130 | 40 | 6010 | 6061T6 |

135 | 10 | 4500 | 6061T6 |

135 | 15 | 6010 | 6061T6 |

135 | 20 | 6010 | 6061T6 |

135 | 25 | 6010 | 6061T6 |

135 | 30 | 6010 | 6061T6 |

140 | 10 | 6010 | 6061T6 |

140 | 15 | 6010 | 6061T6 |

140 | 20 | 6010 | 6061T6 |

140 | 25 | 6010 | 6061T6 |

140 | 30 | 6010 | 6061T6 |

140 | 40 | 6010 | 6061T6 |

145 | 10 | 6010 | 6061T6 |

145 | 15 | 6010 | 6061T6 |

145 | 20 | 6010 | 6061T6 |

145 | 25 | 6010 | 6061T6 |

145 | 30 | 6010 | 6061T6 |

150 | 10 | 6010 | 6061T6 |

150 | 15 | 6010 | 6061T6 |

150 | 20 | 6010 | 6061T6 |

150 | 25 | 6010 | 6061T6 |

150 | 30 | 6010 | 6061T6 |

150 | 40 | 6020 | 6061T6 |

150 | 50 | 6020 | 6061T6 |

155 | 10 | 6020 | 6061T6 |

155 | 15 | 6020 | 6061T6 |

155 | 20 | 6020 | 6061T6 |

155 | 25 | 6020 | 6061T6 |

155 | 30 | 6020 | 6061T6 |

160 | 10 | 6020 | 6061T6 |

160 | 15 | 6020 | 6061T6 |

160 | 20 | 6020 | 6061T6 |

160 | 25 | 6020 | 6061T6 |

160 | 30 | 6020 | 6061T6 |

160 | 40 | 6010 | 6061T6 |

160 | 50 | 6010 | 6061T6 |

165 | 10 | 6020 | 6061T6 |

165 | 15 | 6020 | 6061T6 |

165 | 20 | 6020 | 6061T6 |

165 | 25 | 6020 | 6061T6 |

165 | 30 | 6020 | 6061T6 |

170 | 10 | 6010 | 6061T6 |

170 | 15 | 6010 | 6061T6 |

170 | 20 | 6010 | 6061T6 |

170 | 25 | 6010 | 6061T6 |

170 | 30 | 6020 | 6061T6 |

170 | 40 | 6020 | 6061T6 |

170 | 50 | 6020 | 6061T6 |

175 | 10 | 6020 | 6061T6 |

175 | 15 | 6020 | 6061T6 |

175 | 20 | 6020 | 6061T6 |

175 | 25 | 6020 | 6061T6 |

175 | 30 | 6020 | 6061T6 |

180 | 10 | 6020 | 6061T6 |

180 | 15 | 6020 | 6061T6 |

180 | 20 | 6020 | 6061T6 |

180 | 25 | 6020 | 6061T6 |

180 | 30 | 6020 | 6061T6 |

180 | 40 | 6020 | 6061T6 |

180 | 50 | 6020 | 6061T6 |

185 | 10 | 6020 | 6061T6 |

185 | 15 | 6020 | 6061T6 |

185 | 20 | 6020 | 6061T6 |

185 | 25 | 6020 | 6061T6 |

185 | 30 | 6020 | 6061T6 |

190 | 15 | 6020 | 6061T6 |

190 | 20 | 6020 | 6061T6 |

190 | 25 | 6020 | 6061T6 |

190 | 30 | 6020 | 6061T6 |

190 | 40 | 6020 | 6061T6 |

190 | 50 | 6020 | 6061T6 |

195 | 10 | 6020 | 6061T6 |

195 | 15 | 6020 | 6061T6 |

195 | 20 | 6020 | 6061T6 |

195 | 25 | 6020 | 6061T6 |

195 | 30 | 6020 | 6061T6 |

200 | 20 | 6020 | 6061T6 |

200 | 25 | 6020 | 6061T6 |

200 | 30 | 6020 | 6061T6 |

200 | 40 | 6020 | 6061T6 |

200 | 50 | 5020 | 6061T6 |

200 | 60 | 5020 | 6061T6 |

210 | 25 | 6020 | 6061T6 |

210 | 40 | 5020 | 6061T6 |

210 | 50 | 4020 | 6061T6 |

210 | 60 | 4020 | 6061T6 |

220 | 20 | 5000 | 6061T6 |

220 | 30 | 5000 | 6061T6 |

220 | 40 | 4020 | 6061T6 |

220 | 50 | 4020 | 6061T6 |

220 | 60 | 3020 | 6061T6 |

230 | 20 | 6020 | 6061T6 |

230 | 30 | 6000 | 6061T6 |

230 | 40 | 4000 | 6061T6 |

230 | 50 | 4020 | 6061T6 |

230 | 60 | 3020 | 6061T6 |

240 | 20 | 6000 | 6061T6 |

240 | 30 | 4020 | 6061T6 |

240 | 40 | 3000 | 6061T6 |

240 | 50 | 3000 | 6061T6 |

240 | 60 | 3020 | 6061T6 |

250 | 20 | 3020 | 6061T6 |

250 | 30 | 4020 | 6061T6 |

250 | 40 | 3020 | 6061T6 |

250 | 50 | 3020 | 6061T6 |

250 | 60 | 2520 | 6061T6 |

260 | 20 | 4020 | 6061T6 |

260 | 30 | 2520 | 6061T6 |

260 | 40 | 2520 | 6061T6 |

260 | 50 | 2520 | 6061T6 |

260 | 60 | 2520 | 6061T6 |

270 | 20 | 2150 | 6061T6 |

270 | 30 | 2520 | 6061T6 |

270 | 40 | 2520 | 6061T6 |

270 | 50 | 2020 | 6061T6 |

270 | 60 | 2520 | 6061T6 |

280 | 20 | 4020 | 6061T6 |

280 | 30 | 4020 | 6061T6 |

280 | 40 | 2520 | 6061T6 |

280 | 50 | 2020 | 6061T6 |

280 | 60 | 1520 | 6061T6 |

290 | 20 | 4020 | 6061T6 |

290 | 40 | 1520 | 6061T6 |

290 | 50 | 2000 | 6061T6 |

290 | 60 | 1520 | 6061T6 |

300 | 30 | 2300 | 6061T6 |

300 | 40 | 1420 | 6061T6 |

300 | 50 | 1020 | 6061T6 |

300 | 60 | 1420 | 6061T6 |

310 | 40 | 520 | 6061T6 Forging |

310 | 50 | 520 | 6061T6 Forging |

310 | 60 | 520 | 6061T6 Forging |

320 | 40 | 520 | 6061T6 Forging |

320 | 50 | 520 | 6061T6 Forging |

320 | 60 | 520 | 6061T6 Forging |

330 | 30 | 520 | 6061T6 Forging |

330 | 40 | 520 | 6061T6 Forging |

330 | 50 | 520 | 6061T6 Forging |

330 | 60 | 520 | 6061T6 Forging |

340 | 30 | 520 | 6061T6 Forging |

340 | 40 | 520 | 6061T6 Forging |

340 | 50 | 520 | 6061T6 Forging |

340 | 60 | 520 | 6061T6 Forging |

350 | 30 | 520 | 6061T6 Forging |

350 | 40 | 520 | 6061T6 Forging |

350 | 50 | 520 | 6061T6 Forging |

350 | 60 | 520 | 6061T6 Forging |

360 | 30 | 520 | 6061T6 Forging |

360 | 40 | 520 | 6061T6 Forging |

360 | 50 | 520 | 6061T6 Forging |

360 | 60 | 520 | 6061T6 Forging |

370 | 30 | 520 | 6061T6 Forging |

370 | 40 | 520 | 6061T6 Forging |

370 | 50 | 520 | 6061T6 Forging |

370 | 60 | 520 | 6061T6 Forging |

380 | 30 | 520 | 6061T6 Forging |

380 | 40 | 1010 | 6061T6 Forging |

380 | 50 | 520 | 6061T6 Forging |

380 | 60 | 520 | 6061T6 Forging |

390 | 30 | 520 | 6061T6 Forging |

390 | 40 | 520 | 6061T6 Forging |

390 | 50 | 520 | 6061T6 Forging |

390 | 60 | 520 | 6061T6 Forging |

400 | 30 | 520 | 6061T6 Forging |

400 | 40 | 520 | 6061T6 Forging |

400 | 50 | 520 | 6061T6 Forging |

400 | 60 | 520 | 6061T6 Forging |

400 | 100 | 520 | 6061T6 Forging |

410 | 30 | 520 | 6061T6 Forging |

410 | 40 | 520 | 6061T6 Forging |

410 | 50 | 520 | 6061T6 Forging |

410 | 60 | 520 | 6061T6 Forging |

420 | 30 | 520 | 6061T6 Forging |

420 | 40 | 520 | 6061T6 Forging |

420 | 50 | 520 | 6061T6 Forging |

420 | 60 | 520 | 6061T6 Forging |

430 | 30 | 520 | 6061T6 Forging |

430 | 30 | 1000 | 6061T6 Forging |

430 | 40 | 520 | 6061T6 Forging |

430 | 50 | 520 | 6061T6 Forging |

430 | 60 | 520 | 6061T6 Forging |

440 | 30 | 520 | 6061T6 Forging |

440 | 30 | 1000 | 6061T6 Forging |

440 | 40 | 520 | 6061T6 Forging |

440 | 50 | 520 | 6061T6 Forging |

440 | 60 | 520 | 6061T6 Forging |

450 | 30 | 520 | 6061T6 Forging |

450 | 30 | 1000 | 6061T6 Forging |

450 | 40 | 520 | 6061T6 Forging |

450 | 40 | 1000 | 6061T6 Forging |

450 | 50 | 520 | 6061T6 Forging |

450 | 60 | 520 | 6061T6 Forging |

460 | 30 | 520 | 6061T6 Forging |

460 | 40 | 520 | 6061T6 Forging |

460 | 50 | 520 | 6061T6 Forging |

460 | 60 | 520 | 6061T6 Forging |

470 | 30 | 520 | 6061T6 Forging |

470 | 40 | 520 | 6061T6 Forging |

470 | 50 | 520 | 6061T6 Forging |

470 | 60 | 520 | 6061T6 Forging |

480 | 30 | 520 | 6061T6 Forging |

480 | 40 | 520 | 6061T6 Forging |

480 | 50 | 520 | 6061T6 Forging |

490 | 30 | 520 | 6061T6 Forging |

490 | 40 | 520 | 6061T6 Forging |

490 | 50 | 520 | 6061T6 Forging |

490 | 60 | 520 | 6061T6 Forging |

500 | 30 | 520 | 6061T6 Forging |

500 | 40 | 520 | 6061T6 Forging |

500 | 50 | 520 | 6061T6 Forging |

500 | 60 | 520 | 6061T6 Forging |

500 | 100 | 520 | 6061T6 Forging |

510 | 30 | 520 | 6061T6 Forging |

510 | 40 | 520 | 6061T6 Forging |

510 | 50 | 520 | 6061T6 Forging |

510 | 60 | 520 | 6061T6 Forging |

520 | 30 | 520 | 6061T6 Forging |

520 | 40 | 520 | 6061T6 Forging |

520 | 50 | 520 | 6061T6 Forging |

520 | 60 | 520 | 6061T6 Forging |

530 | 30 | 520 | 6061T6 Forging |

530 | 40 | 520 | 6061T6 Forging |

530 | 50 | 520 | 6061T6 Forging |

530 | 60 | 520 | 6061T6 Forging |

540 | 30 | 520 | 6061T6 Forging |

540 | 40 | 520 | 6061T6 Forging |

540 | 50 | 520 | 6061T6 Forging |

540 | 60 | 520 | 6061T6 Forging |

550 | 30 | 520 | 6061T6 Forging |

550 | 40 | 520 | 6061T6 Forging |

550 | 50 | 520 | 6061T6 Forging |

550 | 60 | 520 | 6061T6 Forging |

670 | 35 | 60 | 6061T6 Forging |

Standard:

ASTM B221, ASTM B241, ASTM B429, AMS-QQ-A-200/8, MIL-DTL-25995 Type A