7175 AMS 4149 and AMS 4201 Applications in Aerospace Engineering

When it comes to building strong, lightweight, and high-performance aircraft structures, material selection is critical. Among the top-performing aerospace-grade materials, 7175 aluminum alloy stands out—especially in tempers like T7351 and T73511. These heat-treated variants offer a balanced combination of strength, toughness, and corrosion resistance, making them ideal for demanding aerospace applications.

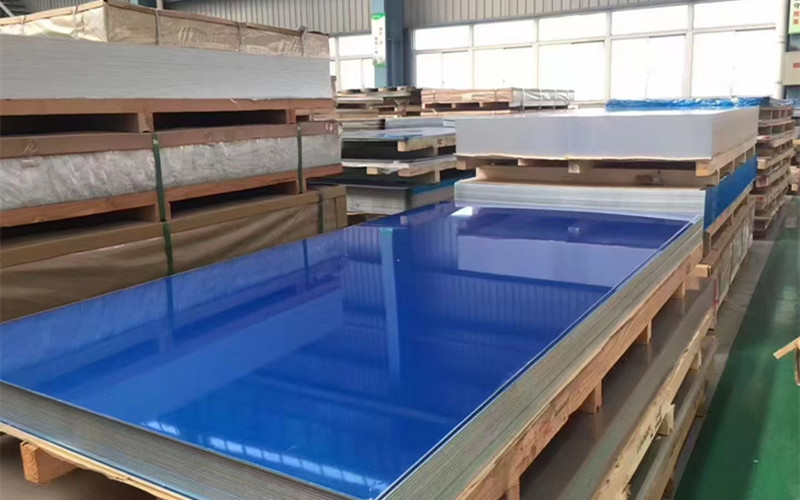

We’ll explore material characteristics of AMS 4149 for 7175 T73511 aluminum forgings and AMS 4201 / ASNA3050 for 7175 T7351 aluminum plates, to see how they are applied in aircraft systems.

What is 7175 Aluminum?

7175 aluminum is a high-strength wrought alloy developed from 7075, with optimized properties for critical aerospace use. It offers:

Excellent fatigue resistance

High yield and tensile strength

Strong stress-corrosion cracking resistance in T7351 and T73511 tempers

Good machinability and dimensional stability

These benefits make it well-suited for both forged components and machined plates in structural aircraft parts.

Applications of AMS 4149 and AMS 4201 Aluminum

7175 aluminum is not a generic metal—it’s tailored for performance in aerospace environments. Here's how different forms of 7175 aluminum are used in practice:

1. Landing Gear Components

Forged 7175 T73511 (AMS 4149) is frequently used in:

Main gear cylinders

Axles and torque arms

Drag links and trunnions

Nose gear fittings

These components endure heavy impact loads and require superior fatigue resistance, which AMS 4149 forgings deliver without adding excessive weight.

2. Aircraft Wing and Fuselage Structures

7175 T7351 plates (AMS 4201 / ASNA3050) are perfect for large machined parts such as:

Wing spars and ribs

Bulkhead reinforcement panels

Floor beams and seat track structures

Fuselage frame components

The T7351 temper ensures minimal distortion during machining, which is essential for parts with tight tolerances.

3. Engine Mounts and Pylon Structures

7175 forgings are trusted in:

Engine pylon fittings

Wing-to-engine mount brackets

Load transfer joints between fuselage and composite wings

These parts must balance weight reduction with the ability to handle high stress and vibration, making 7175 a preferred choice.

4. Rotorcraft & Helicopter Systems

Due to constant vibration and fatigue cycles, helicopters need materials with both strength and ductility. 7175 is used in:

Rotor head assemblies

Control linkages and swashplates

Tail boom fittings and braces

Cabin floor support structures

Its ability to resist cyclic loading ensures long-term reliability in rotorcraft systems.

5. Military Aircraft and UAV Components

7175 aluminum also finds widespread use in defense platforms, including:

Reinforced cockpit frames

UAV fuselage reinforcements

Weapon system support brackets

Avionics housings and radar structures

Its corrosion resistance is critical for high-humidity or salt-spray environments common in naval aviation or remote missions.

6. Aerospace MRO and Spare Part Manufacturing

Because both AMS 4149 and AMS 4201 are internationally recognized standards, they are ideal for:

Aftermarket spares

Aircraft structural repair kits

FAA-compliant replacement parts

Custom machining for upgrades and modifications

Using certified 7175 aluminum ensures airworthiness and long-term traceability in repair and overhaul operations.

Material Standards Of 7175 Aluminum

| Standard | Material Type | Temper | Typical Use Cases |

|---|---|---|---|

| AMS 4149 | Forged Aluminum Alloy | T73511 | Landing gear, pylons, rotor hubs |

| AMS 4201 | Rolled Aluminum Plate | T7351 | Spars, ribs, bulkheads, fuselage panels |

| ASNA3050 | European equivalent | T7351 | Airbus and EASA-compliant aircraft structures |

Aerospace Aluminum 7175 Advantages:

Weight reduction without compromising safety

Compatibility with CNC machining and tight tolerances

Good anodizing response for corrosion protection

Proven performance in both commercial and military aircraft

Whether you're designing a new wing structure, replacing a worn landing gear component, or maintaining a military aircraft, AMS 4149 forgings and AMS 4201 / ASNA3050 plates made from 7175 aluminum offer the reliability, strength, and durability aerospace professionals need.

At Shenzhen Chinalco Metal, we offer stable supply, custom machining, and material traceability for all your 7175 aluminum needs. If you’re looking for certified aluminum forgings or plates for aerospace use, feel free to leave us a message or request a quote today.