What Are Applications of High Frequency Aluminum Welded Tubes?

Aluminum welded tubes are essential components in heat exchange and cooling systems across multiple industries,Thanks to their lightweight, superior heat transfer, and durability, aluminum welded tubes are widely used in heat exchange and cooling systems across industries such as automotive, HVAC, construction, aerospace, and marine engineering. These tubes, made with high-frequency welding technology, offer outstanding heat dissipation, durability, and resistance to high pressure and extreme temperatures. From HVAC systems and power plants to mining equipment and aircraft cooling, aluminum welded tubes provide efficient thermal management solutions. Their ability to withstand corrosive environments, high operating pressures, and mechanical stress makes them the preferred choice for modern engineering applications. In this article, we’ll explore their key applications, material specifications, and advantages in different industries.

Manifold Tube Size Range

Composite Types: Single-layer & Double-layer

Cladding Layers:

· Materials: 4045, 4343, 7072 (Anti-corrosion layer)

· Optional: Zinc coating for enhanced corrosion resistance

Temper: H14

Cladding Ratio: 10 ± 2%

Core Layer:

· Materials: 3003, 3305

Outer Diameter: 9mm – 61mm

Wall Thickness: 1mm – 3.0mm

Manufacturing Process: High-Frequency Welding

1. Condensers

Condensers play a crucial role in heat exchange systems, efficiently converting refrigerant vapor into liquid by dissipating heat. They are widely used in commercial and industrial refrigeration to enhance cooling efficiency, as well as in HVAC systems, where they help air conditioners release indoor heat. In thermal power plants, condensers are essential for converting steam back into water to optimize energy use. Aluminum welded tubes are the preferred choice for these applications due to their excellent heat dissipation, ensuring efficient condensation, and corrosion resistance, which allows for long-term performance in humid and high-moisture environments.

2. Oil Coolers

Oil coolers are essential components in engines and hydraulic systems, efficiently dissipating heat from lubricating oil and transmission fluid to maintain optimal performance. In automotive engines, they help regulate oil temperature, preventing overheating and ensuring smooth operation. Industrial machinery relies on oil coolers to keep hydraulic systems running efficiently by cooling high-temperature oil, while in aerospace and marine applications, they are crucial for proper lubrication in aircraft and ship engines. Aluminum welded tubes are widely used in oil coolers due to their lightweight construction, which reduces overall system weight, high thermal conductivity for efficient heat transfer, and exceptional durability under high-pressure and high-temperature conditions, making them ideal for demanding environments.

3. Automotive Radiators (Including New Energy Vehicles - NEVs)

Radiators are vital components in automotive cooling systems, designed to dissipate excess engine heat and maintain optimal operating temperatures. In traditional combustion engine vehicles, they prevent overheating, ensuring engine efficiency and longevity. For electric and hybrid vehicles (NEVs), radiators play a key role in cooling battery packs and power electronics, helping to enhance performance and extend driving range. Aluminum welded tubes are the preferred choice for radiators due to their high thermal conductivity, which improves cooling efficiency, their lightweight design, which boosts fuel efficiency, and their corrosion resistance, ensuring durability against coolants and harsh environmental conditions.

4. Household Air Conditioners

Air conditioning systems rely on efficient heat transfer to maintain a comfortable indoor environment by moving heat from indoor air to an outdoor condenser unit. Split air conditioners use heat exchangers in both indoor and outdoor units to regulate temperature, while central air conditioning systems provide large-scale cooling for homes and offices. Even portable and window AC units depend on effective heat dissipation to ensure optimal performance. Aluminum welded tubes are widely used in these systems due to their high thermal efficiency, enabling faster cooling, their lower material cost compared to copper, and their lightweight yet durable design, which helps reduce overall system weight without compromising performance.

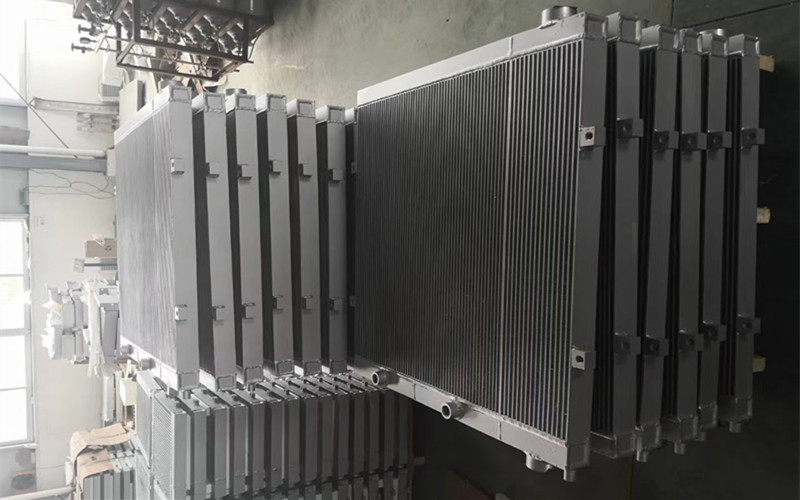

5. Construction Machinery

Heavy-duty machinery relies on efficient cooling systems to maintain optimal performance and prevent overheating during demanding operations. In excavators and loaders, hydraulic cooling systems and radiators help regulate engine and hydraulic fluid temperatures, ensuring smooth operation. Cranes and bulldozers depend on effective heat dissipation to protect mechanical components, while mining equipment requires robust heat management solutions to withstand extreme working conditions. Aluminum welded tubes are ideal for these applications due to their high strength-to-weight ratio, which enhances durability under heavy loads, their exceptional corrosion resistance for extended service life in harsh environments, and their ability to withstand high-pressure conditions, making them a reliable choice for hydraulic systems.