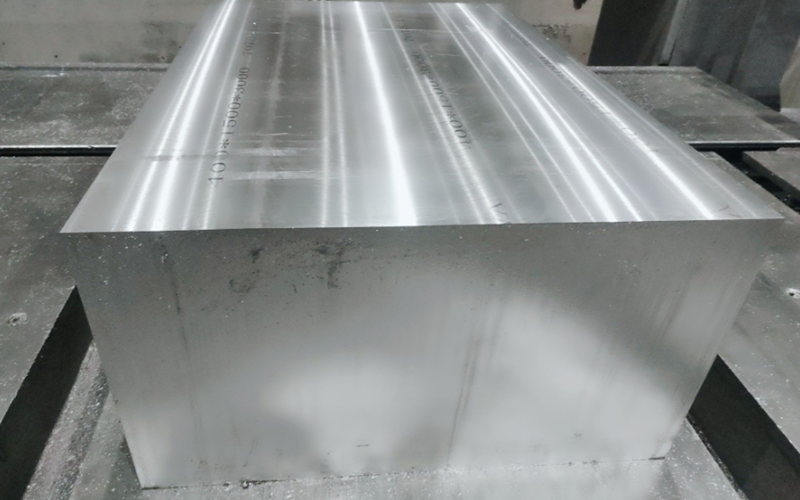

Aluminum 7050 T7451 Plate per AMS4050 Application in Aerospace and Aviation

Aluminum 7050 T7451 plate, certified under AMS 4050, is a high-performance material engineered for demanding aerospace and aviation applications. Known for its excellent strength in thicker sections, superior resistance to stress corrosion cracking, and dependable toughness, it is a preferred choice for structural components where reliability under stress is paramount. This article breaks down everything you need to know about aluminum 7050-T7451 plate per AMS 4050—from specifications to applications and performance comparisons.

What is 7050 T7451?

7050 is a heat-treatable aluminum alloy developed specifically for aerospace use. The T7451 temper indicates it has undergone solution heat treatment, stress relieving by stretching, and artificial aging. This results in a balanced combination of strength, toughness, and corrosion resistance.

Key Characteristics of 7050 T7451 Aluminum Plate:

High Strength in Large Cross-Sections – Better mechanical properties than 7075 in thicker gauges.

Superior SCC (Stress Corrosion Cracking) Resistance – Particularly critical for components exposed to moisture and stress.

Excellent Fatigue Resistance – Essential for flight-critical and load-bearing applications.

Good Machinability – Suitable for precision parts and high-performance machining.

7050-T7451 aluminum is especially suited for components where structural integrity cannot be compromised. It combines lightweight advantages with exceptional mechanical strength, making it an ideal solution for modern aircraft design.

What is AMS 4050 Equivalent To?

AMS 4050 is a material specification by SAE International that governs 7050-T7451 aluminum plate. While there is no direct "equivalent" in commercial standards, AMS 4050 ensures rigorous quality control, mechanical property standards, and ultrasonic inspection protocols required for aerospace use.

AMS 4050 compliance means the material is inspected and certified for aerospace-grade structural applications, particularly where performance in thick sections and resistance to environmental stress are mission-critical.

What is 7050 Grade Aluminum?

7050 aluminum is a high-strength, zinc-based alloy. It is a step above 7075 in performance, particularly when thickness and corrosion resistance are concerns.

Typical Composition of 7050 Aluminum:

Zinc (Zn): 5.7–6.7%

Magnesium (Mg): 1.9–2.6%

Copper (Cu): 2.0–2.6%

Others: Fe, Si, Mn, Cr, Ti (trace)

7050’s heat-treatable nature and chemical composition make it perfect for structural parts exposed to variable loading and harsh operational environments.

7050 T7451 AMS 4050 Properties

7050 T7451 Hardness

The Brinell hardness of aluminum 7050-T7451 is typically around 150 HB, which reflects its high strength and resistance to surface wear. This makes it suitable for aerospace applications involving friction and load.

7050 T7451 Density

The density of 7050-T7451 aluminum is approximately 2.83 g/cm³, slightly higher than 7075. However, its improved corrosion resistance and fatigue strength more than compensate for the small increase in weight, especially in critical components like fuselage frames and wing spars.

AMS 4050 Ultrasonic Inspection

Ultrasonic inspection is a standard requirement under AMS 4050. Each plate must be tested to detect internal discontinuities, such as voids or inclusions. This ensures the material’s reliability in high-stress aerospace structures.

Ultrasonic testing under AMS 4050 standards guarantees a level of quality and consistency that general-purpose aluminum grades cannot match.

Aerospace and Aviation Applications of 7050-T7451 Aluminum Plate

1. Aircraft Structural Components

7050 T7451 is widely used in wing spars, wing ribs, fuselage bulkheads, and lower wing skins—especially in military and commercial aircraft where thickness and strength are critical. The alloy's resistance to stress corrosion makes it reliable in environments with high humidity and cyclic loading.

2. Landing Gear Components

The landing gear endures tremendous stress during takeoff and landing. 7050-T7451’s fatigue strength and high yield strength make it ideal for forged or machined landing gear parts. The alloy supports the design of lighter yet stronger components, enhancing fuel efficiency without sacrificing durability.

3. Jet Engine and Pylon Mounts

In jet engines and their supporting structures (pylons), aluminum 7050 T7451 is valued for its ability to withstand cyclic stresses. It ensures long-term performance without crack propagation, vital for engine mounts and thrust structures.

4. Spacecraft and Satellite Structures

7050 T7451 is used in satellite panels and spacecraft frames, where weight savings and structural rigidity are crucial. The alloy’s low density and dimensional stability under thermal cycling make it well-suited for space environments.

5. Military Aircraft

Military jets like fighter aircraft require materials that withstand extreme G-forces and operational loads. 7050-T7451 is often used for its exceptional performance in thick sections and resistance to SCC, making it a go-to alloy for tactical aircraft and unmanned aerial vehicles (UAVs).

Comparison: 7050-T7451 vs. 7075-T651 vs. 7475-T7351

| Property | 7050-T7451 (AMS 4050) | 7075-T651 | 7475-T7351 |

|---|---|---|---|

| Ultimate Tensile Strength | 83 ksi (572 MPa) | 83 ksi (572 MPa) | 78 ksi (538 MPa) |

| Yield Strength | 73 ksi (503 MPa) | 73 ksi (503 MPa) | 69 ksi (476 MPa) |

| Elongation | 10–12% | 9–11% | 13–15% |

| Fatigue Strength | Excellent | Very Good | Good |

| SCC Resistance | Superior | Moderate | Superior |

| Fracture Toughness | High (~40–45 MPa√m) | Moderate | Very High (~55 MPa√m) |

| Density | 2.83 g/cm³ | 2.81 g/cm³ | 2.81 g/cm³ |

| Machinability | Good | Excellent | Good |

| Weldability | Poor | Poor | Poor |

| Common Use | Thick aerospace parts | General aircraft | Fracture-critical parts |

This comparison highlights that while all three alloys are strong candidates, 7050-T7451 per AMS 4050 stands out for thick structural aerospace components, offering a rare combination of strength, toughness, and corrosion resistance.

Shenzhen Chinalco Metal supplies certified aluminum 7050 T7451 plates compliant with AMS 4050 standards. Our materials are suitable for aerospace OEMs, MROs, and advanced machining centers. For pricing, datasheets, or consultation, feel free to contact us or leave a message. Let’s help you achieve lightweight strength without compromise.