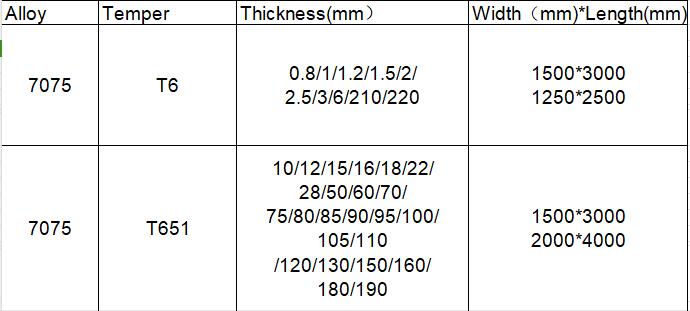

7075 T651 Aluminum Aircraft Plate T6 Temper

7075 T651 and T6 aluminum plates are highly valued in the aerospace industry for their exceptional strength, fatigue resistance, and machinability. These properties make them ideal for a wide range of aerospace applications, including aircraft fuselage and wings, fasteners, landing gear components, structural parts, helicopter rotor blades, and engine parts. The advanced tempering processes further enhance the alloy's performance, ensuring the safety, reliability, and efficiency of aerospace structures and components.

7075 Alloy Properties

1. Composition:7075 aluminum alloy typically consists of the following elements:

Aluminum (Al): 87.1-91.4%

Zinc (Zn): 5.6-6.1%

Magnesium (Mg): 2.1-2.5%

Copper (Cu): 1.2-1.6%

Chromium (Cr): 0.18-0.28%

2. Strength and Durability:7075 aluminum alloy is renowned for its high strength, comparable to some steels, and excellent fatigue resistance. These properties are crucial for aerospace applications where materials are subjected to high stresses and cyclic loads.

3. Corrosion Resistance:While 7075 aluminum alloy has good corrosion resistance, especially in the T651 and T66 tempers, it is often coated or treated to enhance its corrosion protection, making it suitable for harsh aerospace environments.

4. Machinability:7075 aluminum alloy exhibits excellent machinability, making it easy to work with using various machining processes. This property is essential for creating precise and complex aerospace components.