What is the difference between 6101 and 6063 aluminum?

As typical representatives of 6 series aluminum alloys, 6061, 6063 and 6101 aluminum alloys have wide application value in the industrial field. This article will conduct a systematic technical analysis of these three alloys from four aspects: material properties, application fields, product forms and selection recommendations. First, we will compare their chemical composition and mechanical properties in detail; secondly, we will explain their main application scenarios; then, we will introduce common product processing forms; finally, based on actual engineering needs, we will provide professional selection guidance recommendations.

Chemical Composition Comparison (wt%)

| Element/Alloy | 6061 | 6063 | 6101 |

|---|---|---|---|

| Si | 0.4-0.8 | 0.2-0.6 | 0.3-0.7 |

| Fe | ≤0.7 | ≤0.35 | ≤0.5 |

| Cu | 0.15-0.4 | ≤0.1 | ≤0.05 |

| Mn | ≤0.15 | ≤0.1 | ≤0.03 |

| Mg | 0.8-1.2 | 0.45-0.9 | 0.35-0.8 |

| Cr | 0.04-0.35 | ≤0.1 | - |

| Zn | ≤0.25 | ≤0.1 | ≤0.1 |

| Ti | ≤0.15 | ≤0.1 | - |

| Al | Balance | Balance | Balance |

Key Differences:

6061: Higher copper (Cu) and chromium (Cr) content → Better strengthening effect

6101: Ultra-low copper (≤0.05%) → Superior electrical conductivity

6063: Lower magnesium (Mg) content → Optimized for extrusion

6061 T6, 6063 T5 and 6101 T6 Aluminum Properties

| Property/Alloy | 6061 | 6063 | 6101 | Key Differences |

|---|---|---|---|---|

| Density (g/cm³) | 2.70 | 2.70 | 2.70 | Identical density |

| Tensile Strength (MPa) | 290-310 | 190-240 | 150-180 | 6061 > 6063 > 6101 |

| Yield Strength (MPa) | 240-270 | 170-210 | 120-150 | 6061 has highest load capacity |

| Elongation (%) | 8-12 | 10-12 | 15-20 | 6101 offers best ductility |

| Hardness (Brinell) | 95-100 | 60-75 | 50-60 | 6061 is most wear-resistant |

| Load Capacity Ratio | 100% (Ref) | ~70-80% | ~50-60% | 6061 withstands greater weight at same dimensions |

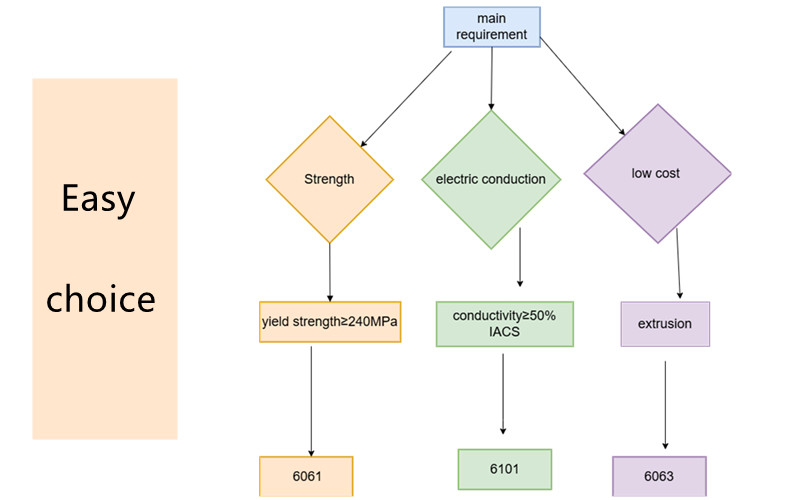

How to choose the suitable material easily?

Applications

6061 aluminum:

As an aviation-grade structural material, 6061 has become the main alloy in the industrial field due to its excellent comprehensive mechanical properties. This material is strengthened by Mg2Si phase, and the tensile strength can reach 310MPa in the T6 state. It is widely used in high-stress scenarios such as aircraft parts and automated mechanical frames. Its welding performance is relatively poor, and 4043 welding wire must be used in combination with pulse welding process.

A representative product of electrical aluminum, 6101 has a conductivity of more than 55% IACS by strictly controlling the Fe and Si impurity content. This alloy is mainly used in conductive parts such as power busbars and transformer windings. Its strength is only 50% of 6061, but its corrosion resistance is better than that of conventional industrial aluminum alloys. Special annealing process can further improve its conductivity.

6063 Aluminum:The standard choice of architectural aluminum profiles, 6063 is known for its excellent extrusion forming performance. After online quenching, this alloy can obtain a good surface finish and excellent anodizing effect. Typical applications include civil products such as doors, windows, curtain walls, and radiators. Although its strength is not as good as 6061, it fully meets the requirements of building specifications

Forms of 6101 6063 6061 aluminum

Shenzhen Chinalco Metal supply 6101, 6061, 6063 in forms of aluminum bus bar, aluminum plate/sheet, aluminum tube, aluminum round bar.