What powder is used in 3D printing?

Unveiling 3D Printing Powder Materials: Exploring Diverse Printing Possibilities

Powder materials, as an essential medium for 3D printing, play a critical role in determining the quality and performance of the final product. The type and properties of these powders directly influence the outcome of the printing process.

Plastic Powders: The Entry-Level Choice for 3D Printing

Plastic powders, such as polylactic acid (PLA) and acrylonitrile-butadiene-styrene (ABS), are popular choices for beginners due to their low cost and ease of use. PLA powder, derived from renewable resources, is non-toxic and odorless during printing, making it an environmentally friendly option. ABS powder, on the other hand, offers higher strength and heat resistance, making it suitable for creating complex models and functional parts.

Ceramic Powders: Crafting Exquisite Artworks and High-Performance Components

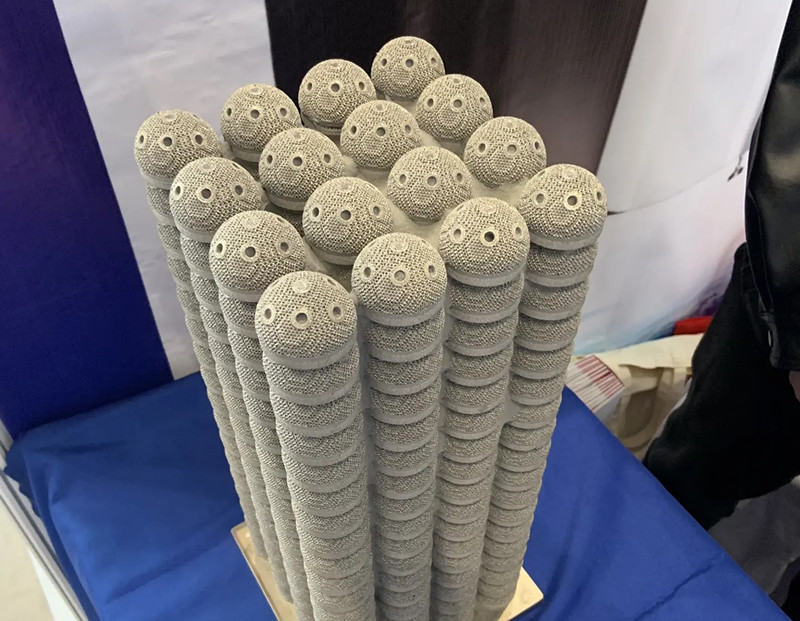

Ceramic powders have gained prominence in the 3D printing field due to their high hardness, excellent wear resistance, and biocompatibility. Whether used to produce intricate artworks or high-performance components for medical devices and aerospace applications, ceramic powders deliver outstanding results. By carefully controlling printing parameters, smooth surfaces and intricate details can be achieved in ceramic products.

Metal Powders: Ushering in a New Era of Industrial Manufacturing

Metal powders come in various types, including titanium, nickel, stainless steel, and aluminum. Each type has unique characteristics suitable for different applications. For instance, titanium powder, known for its high strength, low density, and biocompatibility, is widely used in medical devices and aerospace components. Nickel powder, with its excellent high-temperature resistance and corrosion resistance, is commonly applied in gas turbine blades and high-temperature alloy parts.

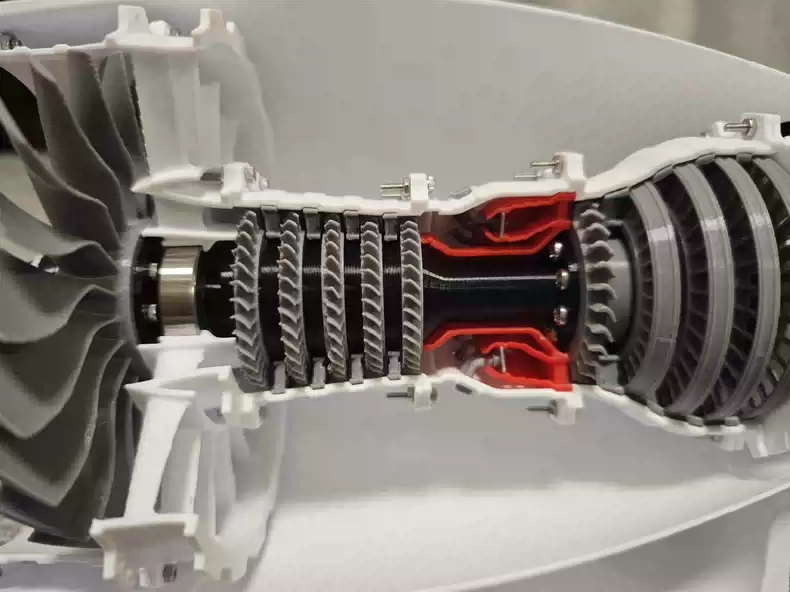

In the aerospace sector, 3D printing has become indispensable. Using metal powders, lightweight and high-strength engine components and aircraft structures can be manufactured. This reduces aircraft weight, improves fuel efficiency, shortens manufacturing cycles, and lowers production costs. For example, an aerospace company successfully 3D-printed a new type of engine blade using nickel-based alloy powder, providing superior high-temperature and fatigue resistance, significantly enhancing engine efficiency and reliability.

In the automotive industry, 3D printing shows immense potential. Metal powder 3D printing can be utilized for prototype design and mass production of automotive parts. The technology enables the rapid manufacturing of complex components, reducing development costs and shortening R&D cycles. For instance, an automotive company successfully produced a new engine cylinder head using aluminum alloy powder, achieving excellent heat dissipation and strength, thereby improving overall engine performance.

In the medical field, metal powder 3D printing has demonstrated remarkable capabilities. With its excellent biocompatibility and mechanical properties, metal powders are used to manufacture various medical devices and implants. For example, titanium powder enables the production of personalized artificial joints and dental implants tailored to patients' needs, providing better fit and comfort, and improving treatment outcomes. Additionally, 3D printing can be applied to surgical instruments and medical device components, enhancing manufacturing efficiency and precision.

Beyond these industries, metal powder 3D printing has broad application prospects in mold making, energy equipment, and more. As 3D printing technology continues to evolve, metal powder 3D printing is expected to make even greater contributions across a wider range of fields.

Conclusion

As an indispensable material in 3D printing technology, metal powder holds immense potential for innovation and transformation across industries. By understanding the properties of different metal powders and their application scenarios, we can better leverage 3D printing technology to drive innovation and progress in various sectors.