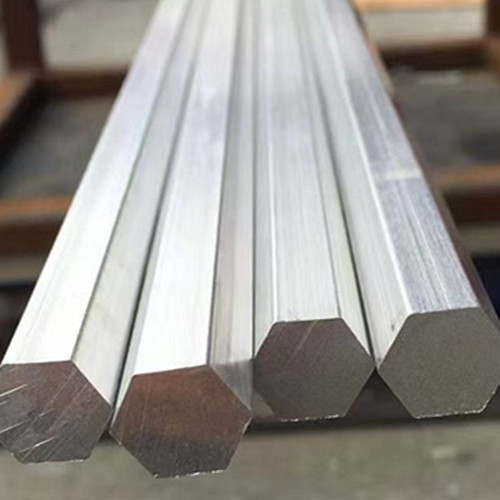

7075-T73 forged Aluminum AMS 4126 Stock

AMS 4126 7075-T73 forged aluminum alloy is a high-strength, corrosion-resistant aerospace-grade material widely used in applications where exceptional strength, fatigue resistance, and long-term durability are critical—such as in the aerospace, automotive, defense, and high-performance industrial sectors.

This material is based on 7075 aluminum alloy, a high-strength alloy primarily composed of zinc. It offers excellent mechanical properties and is well-known for its performance under stress. AMS 4126 is the corresponding Aerospace Material Specification, which defines the chemical composition, mechanical properties, processing forms, and quality control standards for this forged aluminum alloy.

AMS 4126 is supplied in the form of forgings, including die forgings, hand forgings, and forging stock, allowing for customized processing to meet specific engineering needs.

The heat treatment condition is T73, an overaged temper specifically designed to enhance the material’s resistance to stress corrosion cracking, making it more reliable in harsh environments while maintaining high strength.

In summary, AMS 4126 7075-T73 forged aluminum is a premium material that offers an ideal balance of high strength, excellent fatigue performance, and superior corrosion resistance, making it well-suited for critical structural components and demanding service conditions.

Mechanical Properties of 7075-T73 forged Aluminum AMS 4126

| Temper | Tensile Ultimate MPA | Yield Strength MPA | Elongation % | Hardness Brinell |

| T73 | 448 | 379 | 8-10 | 140-150 |

Key Features & Advantages of AMS 4126 7075-T73 Forged Aluminum

1. High Strength-to-Weight Ratio

Ultimate tensile strength: 65 ksi (448 MPa)

Yield strength: 55 ksi (379 MPa)

Low density: 2.81 g/cm³, providing excellent weight savings

Ideal for lightweight, high-load applications

2. Superior Stress Corrosion Resistance

T73 temper significantly enhances corrosion resistance

Excellent for marine, aerospace, and industrial environments

Provides better SCC (stress corrosion cracking) resistance than T6-treated 7075

3. Excellent Fatigue Strength & Durability

Fatigue strength: 23 ksi (159 MPa)

Withstands cyclic loading and vibration

Maintains structural integrity under high mechanical stress

Perfect for aircraft and automotive components

4. Precision Forging Capability

Available in:

Die forgings

Hand forgings

Forging stock

Enables tight tolerances and near-net shape production

Reduces machining costs and enhances grain structure for superior mechanical performance

5. Good Machinability & Surface Finish

Easier to machine than many other high-strength aluminum alloys

Capable of achieving smooth surface finishes

Recommended to use oil-based lubricants for optimal machining results

6. Versatile & Wide-Ranging Applications

AMS 4126 7075-T73 forged aluminum is widely utilized in aerospace, defense, automotive, and heavy industry sectors. It is particularly well-suited for structural and load-bearing components such as landing gear parts, aircraft bulkheads, military vehicle frames, and high-performance automotive components. In addition to transportation and defense, the alloy is also used in the manufacturing of high-pressure vessels, marine equipment, and large-scale structural frameworks—anywhere that requires a blend of high strength, fatigue resistance, and superior corrosion protection.

Application of AMS 4126 7075-T73 Forged Aluminum

AMS 4126 7075-T73 forged aluminum is a premium choice for applications demanding a combination of high strength, lightweight design, and exceptional corrosion resistance. It is widely used across aerospace, defense, automotive, and industrial sectors.

In aerospace and defense, this forged aluminum alloy is ideal for structural components such as landing gear, fuselage frames, wing spars, and engine mounts, where both load-bearing strength and weight reduction are critical. It's also used in missile parts, armored vehicle structures, and aircraft weapon mounts, thanks to its fatigue strength and SCC resistance.

In automotive and motorsport, AMS 4126 supports high-performance needs in racing engine parts, suspension systems, chassis components, and brake assemblies, where low weight and high durability directly impact speed and efficiency.

In industrial and marine environments, it’s perfect for high-load machine parts, hydraulic pressure vessels, and corrosion-resistant marine components. It ensures structural strength with reduced weight, making it ideal for both stationary and mobile systems.

This material is engineered for demanding conditions—whether in the sky, on the track, or in the factory. It's a proven solution for long-term performance and structural reliability.

How to find the right solution for your application?

At Shenzhen Chinalco Metal, we supply high-quality 7075 forged aluminum products with stable inventory and support for customized forgings based on your drawings. Whether you need aerospace-grade components or high-performance automotive parts, our team is ready to help.

👉 contact Shenzhen Chinalco Metal to discuss your requirements today.