AMS4186 Aerospace Aluminum Extruded Bar 7075 T6 T6511

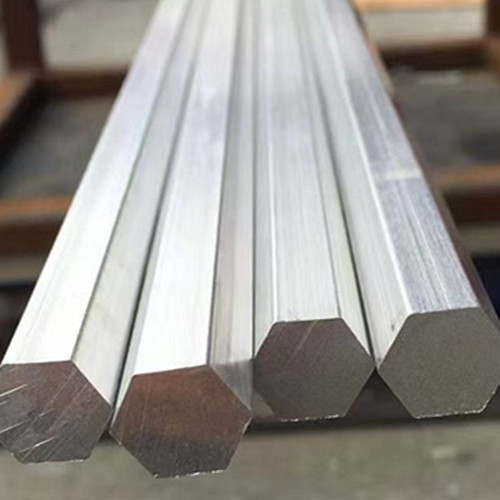

Aerospace Aluminum extruded bar 7075 T6 T6511

Aluminum 7075 has good fatigue strength and average machinability. It is not weld able and has less corrosion resistance than other aluminum alloys. The mechanical properties depend on the temper of the material. Commonly used in the bicycle industry, aircraft structures. We stock 7075-T6,7075-T651, 7075-T6511, 7075-T7351, and 7075-T76511.

Available shapes: Flats, squares and rounds

Tempers: T6, T651, T73, T7351

Standards: ASTM B211, AMS 4122, AMS 4123, AMS 4124, AMS4186, AMS-QQ-A-225/9, ASTM B221, AMS 4154, AMS 4166, AMS 4167, AMS-QQ-A-200/11

Stock list

EXTRUDED ROUND BAR | Diameter | Length |

7075 T6 T6511 | 5mm | 2500mm/3000mm |

7075 T6 T6511 | 10mm | 2500mm/3000mm |

7075 T6 T6511 | 30mm | 2500mm/3000mm |

7075 T6 T6511 | 40mm | 2500mm/3000mm |

7075 T6 T6511 | 50mm | 2500mm/3000mm |

7075 T6 T6511 | 60mm | 2500mm/3000mm |

7075 T6 T6511 | 70mm | 2500mm/3000mm |

7075 T6 T6511 | 80mm | 2500mm/3000mm |

7075 T6 T6511 | 90mm | 2500mm/3000mm |

7075 T6 T6511 | 100mm | 2500mm/3000mm |

7075 T6 T6511 | 120mm | 2500mm/3000mm |

7075 T6 T6511 | 140mm | 2500mm/3000mm |

7075 T6 T6511 | 160mm | 2500mm/3000mm |

7075 T6 T6511 | 180mm | 2500mm/3000mm |

7075 T6 | 200mm | 2500mm/3000mm |

7075 T6 | 230mm | 2500mm/3000mm |

7075 T6 | 250mm | 2500mm/3000mm |

7075 T6 | 280mm | 2500mm/3000mm |

7075 T6 | 300mm | 2500mm/3000mm |

7075 T6 | 400mm | 2500mm |

7075 T6 | 500mm | 2500mm |

7075 T6 | 580mm | 2500mm |

Aluminum extruded bar 7075 T6 T6511Applications:

Aircraft Structural Parts

Extrusions

Shop Fittings

Tools