AMS 4152 Aluminum extruded rod bar 2024 T3 T4

Aluminum alloy 2024 is widely recognized as the “aircraft alloy” and is commonly used in machining rods. This alloy is highly sought after for cold heading and roll threading applications due to its exceptional strength and fatigue resistance. It is particularly useful in parts where a high strength-to-weight ratio is required. Machinability is excellent, whether in the heat-treated or annealed condition. The alloy is prominently featured in aircraft structural components, truck wheels, medical instruments, and screw machine products. Our inventory includes 2024-T3,T351, 2024-T3511, and 2024-T4 variants.

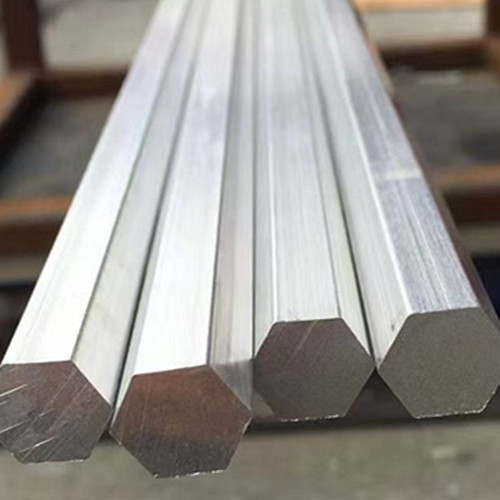

Available shapes: Flats, squares and rounds

Tempers: T351, T3511 & T4

Specifications: ASTM B211, AMS 4120, AMS 4339, AMS-QQ-A-225/6, ASTM B221, AMS 4152, AMS 4164, AMS 4165, AMS-QQ-A-200/3

Stock list

EXTRUDED ROUND BAR | Diameter | Length |

2024 T3 T4 | 5/6/7/8/9mm | 2500mm/3000mm |

2024 T3 T4 | 10/11/12/13/14/15mm | 2500mm/3000mm |

2024 T3 T4 | 16/17/18/19/20mm | 2500mm/3000mm |

2024 T3 T4 | 21/22/23/24/25mm | 2500mm/3000mm |

2024 T3 T4 | 26/27/28/29/30mm | 2500mm/3000mm |

2024 T3 T4 | 31/32/33/34/35mm | 2500mm/3000mm |

2024 T3 T4 | 36/38/39/40mm | 2500mm/3000mm |

2024 T3 T4 | 42/45/46/48/50mm | 2500mm/3000mm |

2024 T3 T4 | 52/55/57/58/60mm | 2500mm/3000mm |

2024 T3 T4 | 62/65/70/75mm | 2500mm/3000mm |

2024 T3 T4 | 80/85mm | 2500mm/3000mm |

2024 T3 T4 | 90/95mm | 2500mm/3000mm |

2024 T3 T4 | 100/105/110/115mm | 2500mm/3000mm |

2024 T3 T4 | 120/125/130/135mm | 2500mm/3000mm |

2024 T3 T4 | 140/145/150/155mm | 2500mm/3000mm |

2024 T3 T4 | 160165/170/175mm | 2500mm/3000mm |

2024 T3 T4 | 180/185mm | 2500mm/3000mm |

2024 T3 T4 | 190/200mm | 2500mm/3000mm |

2024 T3 T4 | 210/220/230mm | 2500mm/3000mm |

2024 T3 T4 | 240/250260mm | 2500mm/3000mm |

2024 T3 T4 | 270/280/290mm | 2500mm/3000mm |

2024 T3 T4 | 300/310/320/330/340mm | 2500mm/3000mm |

2024 T3 T4 | 350/360/370/380/390/400mm | 2500mm |

2024 T3 T4 | 410/420/450/460/500mm | 2500mm |

2024 T3 T4 | 560mm | 2500mm |

Aluminum extruded rod bar 2024 T3 T4 Applications:

aircraft structural components,

truck wheels,

medical instruments,

ascrew machine products