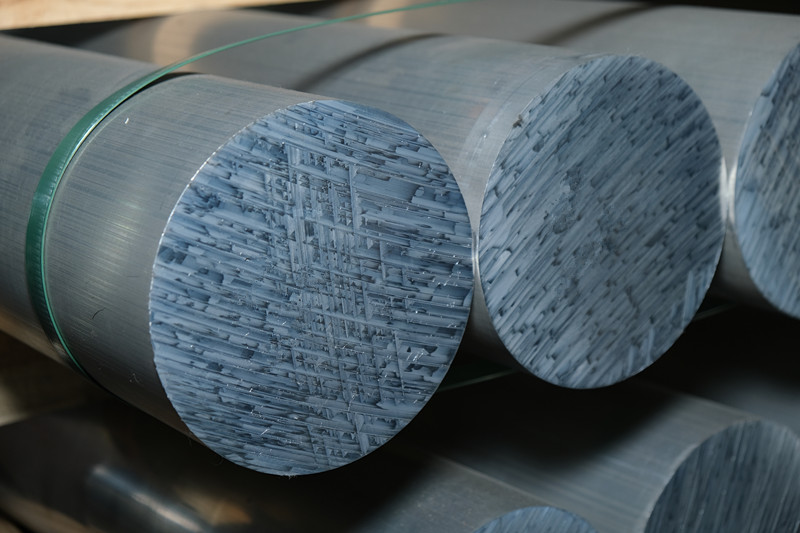

Cold Drawn Finished 7075 T6 T6511 Aluminum aerospace round bar

What is Cold-drawn 7075 aluminum rods?

Cold-drawn 7075 aluminum rods are aluminum products made using the cold drawing process. 7075 aluminum alloy, known for its excellent strength, corrosion resistance, and good machinability, is widely used in aerospace, military, and other fields. After undergoing the cold drawing process, the 7075 aluminum rods show significantly improved dimensional accuracy and surface finish, while their physical and mechanical properties are enhanced. This process ensures high precision and superior surface quality, making these rods particularly suitable for applications requiring high strength and precise dimensions.

Available shapes: Flats, squares and rounds

Tempers: T6, T651, T73, T7351

Specifications: ASTM B211, AMS 4122, AMS 4123, AMS 4124, AMS4186, AMS-QQ-A-225/9, ASTM B221, AMS 4154, AMS 4166, AMS 4167, AMS-QQ-A-200/11

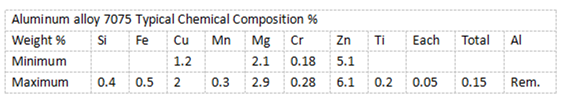

Chemical Composition

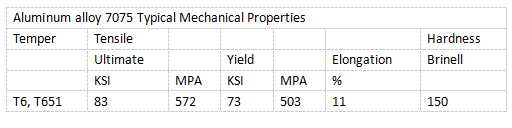

Mechanical Properties

Stock list of Cold Drawn 7075 T6 T6511 Aluminum aerospace round bar

Alloy | Temper | Dia.(mm) | Length(mm) |

7075 | T6 | 2.5 | 2500/3000 |

7075 | T6 | φ3 | 2500/3000 |

7075 | T6 | 3.5 | 2500/3000 |

7075 | T6 | φ4 | 2500/3000 |

7075 | T6 | 4.5 | 2500/3000 |

7075 | T6 | φ5 | 2500/3000 |

7075 | T6 | 5.5 | 2500/3000 |

7075 | T6 | φ6 | 2500/3000 |

7075 | T6 | 6.5 | 2500/3000 |

7075 | T6 | φ7 | 2500/3000 |

7075 | T6 | 7.5 | 2500/3000 |

7075 | T6 | φ8 | 2500/3000 |

7075 | T6 | 8.5 | 2500/3000 |

7075 | T6 | φ9 | 2500/3000 |

7075 | T6 | φ10 | 2500/3000 |

7075 | T6 | φ11 | 2500/3000 |

7075 | T6 | φ12 | 2500/3000 |

7075 | T6 | φ13 | 2500/3000 |

7075 | T6 | φ14 | 2500/3000 |

7075 | T6 | φ15 | 2500/3000 |

7075 | T6 | φ16 | 2500/3000 |

7075 | T6 | φ17 | 2500/3000 |

7075 | T6 | φ18 | 2500/3000 |

7075 | T6 | φ19 | 2500/3000 |

7075 | T6 | φ20 | 2500/3000 |

7075 | T6 | φ21 | 2500/3000 |

7075 | T6 | φ22 | 2500/3000 |

7075 | T6 | φ23 | 2500/3000 |

7075 | T6 | φ24 | 2500/3000 |

7075 | T6 | φ25 | 2500/3000 |

7075 | T6 | φ26 | 2500/3000 |

7075 | T6 | φ27 | 2500/3000 |

7075 | T6 | φ28 | 2500/3000 |

7075 | T6 | φ29 | 2500/3000 |

7075 | T6 | φ30 | 2500/3000 |

Applications:

Aerospace Industry

7075 cold-drawn rods are widely used in the aerospace sector due to their excellent strength-to-weight ratio, high tensile strength, and resistance to fatigue. These rods are used to manufacture critical components like aircraft fuselage frames, wing structures, landing gears, and other high-stress components. The high precision achieved through cold drawing ensures tight tolerances, making them ideal for components that require exact dimensions and high reliability.Military and Defense Applications

In the military and defense industries, 7075 aluminum cold-drawn rods are essential for making lightweight, high-strength parts for weapons, armor, and military vehicles. Due to their superior strength and corrosion resistance, they are used in components such as gun barrels, tactical vehicle parts, and structural components of military aircraft. Their ability to withstand harsh environments while maintaining structural integrity is crucial in these demanding applications.Sports Equipment

The combination of high strength, durability, and light weight makes 7075 cold-drawn rods ideal for manufacturing high-performance sports equipment. They are used to produce parts such as bicycle frames, ski poles, golf club shafts, and other precision components in outdoor sports. The rods’ excellent surface finish also contributes to the aesthetic and functional qualities of sports equipment.Precision Engineering & Manufacturing

7075 cold-drawn rods are also employed in precision engineering applications, such as tooling, automotive parts, and custom machinery components. The high dimensional accuracy, smooth surface, and enhanced mechanical properties make them suitable for producing intricate parts that require fine tolerances and high mechanical performance, such as fasteners, shafts, and connectors in the automotive and industrial sectors.