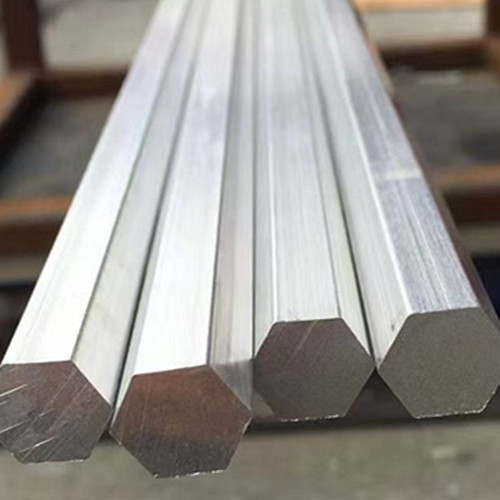

Cold Finished Drawn Aluminum rod bar 6063 T6

Aluminium Alloy 6063 (UNS A96063) is an aluminum alloy recognized for its excellent extrudability and high-quality surface finish. Often referred to as an architectural alloy, it is ideal for standard architectural shapes, custom solids, and heatsinks. Additionally, its good electrical conductivity makes it suitable for use in electrical applications, particularly in T5, T52, and T6 tempers.

This alloy offers high corrosion resistance and superior finishing characteristics. It has average machinability and is suitable for both hot and cold forming. Due to its conductivity, 6063 is also utilized in electrical substations. It is commonly employed in the manufacture of pipe railings, furniture, windows, stair rails, and similar applications.

Stock list of Cold finished (drawn) Aluminum rod bar 6063 T6

Available shapes: Flats, squares and rounds

Tempers: T6, T651, T6511

Specifications: ASTM B221, AMS 4156, AMS QQ-A-200/9

Alloy | Temper | Dia.(mm) | Length(mm) |

6063 | T6 | φ5 | 2500/3000 |

6063 | T6 | 5.5 | 2500/3000 |

6063 | T6 | φ6 | 2500/3000 |

6063 | T6 | 6.5 | 2500/3000 |

6063 | T6 | φ7 | 2500/3000 |

6063 | T6 | 7.5 | 2500/3000 |

6063 | T6 | φ8 | 2500/3000 |

6063 | T6 | 8.5 | 2500/3000 |

6063 | T6 | φ9 | 2500/3000 |

6063 | T6 | φ10 | 2500/3000 |

6063 | T6 | 10.5 | 2500/3000 |

6063 | T6 | φ11 | 2500/3000 |

6063 | T6 | 11.5 | 2500/3000 |

6063 | T6 | φ12 | 2500/3000 |

6063 | T6 | 12.5 | 2500/3000 |

6063 | T6 | φ13 | 2500/3000 |

6063 | T6 | 13.5 | 2500/3000 |

6063 | T6 | φ14 | 2500/3000 |

6063 | T6 | φ15 | 2500/3000 |

6063 | T6 | 15.5 | 2500/3000 |

6063 | T6 | φ16 | 2500/3000 |

6063 | T6 | φ17 | 2500/3000 |

6063 | T6 | φ18 | 2500/3000 |

6063 | T6 | φ19 | 2500/3000 |

6063 | T6 | φ20 | 2500/3000 |

6063 | T6 | φ21 | 2500/3000 |

6063 | T6 | φ22 | 2500/3000 |

6063 | T6 | φ23 | 2500/3000 |

6063 | T6 | φ24 | 2500/3000 |

6063 | T6 | φ25 | 2500/3000 |

6063 | T6 | φ26 | 2500/3000 |

6063 | T6 | φ27 | 2500/3000 |

6063 | T6 | φ28 | 2500/3000 |

6063 | T6 | φ29 | 2500/3000 |

6063 | T6 | φ30 | 2500/3000 |