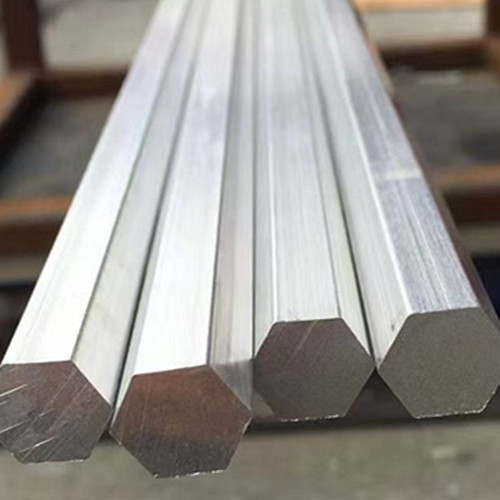

DTD 5014A 2618 T6 Aluminum extruded bar

What is DTD 5014A Material?

Aluminium Alloy 2618, also known as DTD 5014A, is a high-performance aluminum alloy specifically designed for demanding environments. Its primary components include copper and magnesium, giving it exceptional strength and good machinability. Compared to regular aluminum alloys, 2618 maintains stable performance even under high temperatures, making it a popular choice in industries that require materials to withstand extreme conditions.

In aerospace and defense, this alloy is commonly used to manufacture critical components like aircraft engine pistons and rotating parts. Aircraft parts endure extreme temperature changes and immense pressure, especially during high-speed or long-duration flights. Thanks to its heat resistance and excellent fatigue strength, 2618 alloy is ideal for ensuring reliability in these applications.

Beyond aerospace, 2618 is also favored in high-performance motorsports. In racing engines, it’s often used to produce pistons and other parts that endure extreme heat and pressure, ensuring stability even in intense competition.

Additionally, 2618 alloy offers moderate resistance to atmospheric corrosion, meaning it’s less likely to rust or oxidize over time, reducing maintenance costs. In summary, Aluminium Alloy 2618 (DTD 5014A) is a reliable, durable, and high-performing material, perfectly suited for applications requiring high temperature and pressure resistance over prolonged periods.

Are 2618 Aluminum Alloy and DTD 5014A the Same Material?

Yes, Aluminium Alloy 2618 and DTD 5014A refer to the same material, but they represent different naming conventions:

2618 is an international designation based on the alloy’s composition and performance characteristics.

DTD 5014A is a British "Defence Standard" code, used in aerospace and defense to signify that the material meets specific military or aviation standards.

In simple terms, 2618 is the generic name, while DTD 5014A indicates compliance with a particular standard. When sourcing this material, either name refers to the same high-performance aluminum alloy.

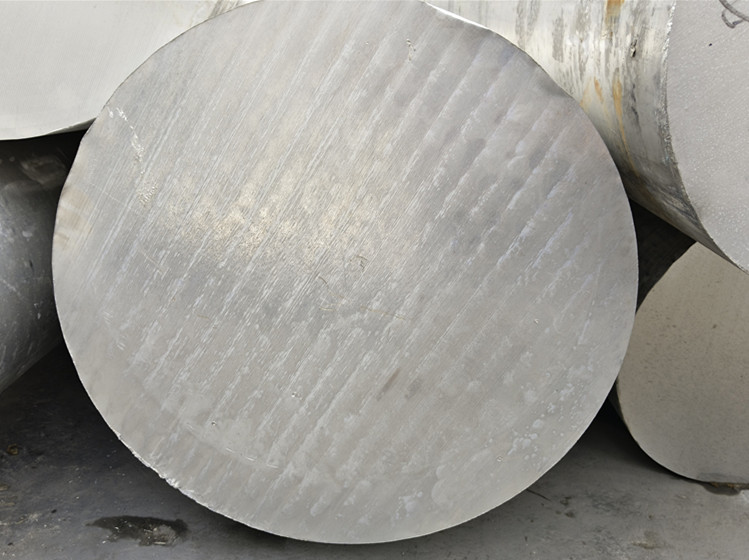

Stock list of DTD 5014 A 2618 T6 Aluminum bar

Alloy | Temper | Dia.(mm) | Length(mm) |

2618 | T6 | Φ20 | 2500/3000 |

2618 | T6 | Φ25 | 2500/3000 |

2618 | T6 | Φ30 | 2500/3000 |

2618 | T6 | Φ35 | 2500/3000 |

2618 | T6 | Φ40 | 2500/3000 |

2618 | T6 | Φ45 | 2500/3000 |

2618 | T6 | Φ50 | 2500/3000 |

2618 | T6 | Φ55 | 2500/3000 |

2618 | T6 | Φ60 | 2500/3000 |

2618 | T6 | Φ65 | 2500/3000 |

2618 | T6 | Φ70 | 2500/3000 |

2618 | T6 | Φ75 | 2500/3000 |

2618 | T6 | Φ80 | 2500/3000 |

2618 | T6 | Φ85 | 2500/3000 |

2618 | T6 | Φ90 | 2500/3000 |

2618 | T6 | Φ95 | 2500/3000 |

2618 | T6 | Φ100 | 2500/3000 |

2618 | T6 | Φ110 | 2500/3000 |

2618 | T6 | Φ115 | 2500/3000 |

2618 | T6 | Φ120 | 2500/3000 |

2618 | T6 | Φ130 | 2500/3000 |

2618 | T6 | Φ140 | 2500/3000 |

2618 | T6 | Φ145 | 2500/3000 |

2618 | T6 | Φ150 | 2500/3000 |

2618 | T6 | Φ160 | 2500/3000 |

2618 | T6 | Φ170 | 2500/3000 |

2618 | T6 | Φ180 | 2500/3000 |

2618 | T6 | Φ190 | 2500/3000 |

2618 | T6 | Φ200 | 2500/3000 |

2618 | T6 | Φ210 | 2500/3000 |

2618 | T6 | Φ220 | 2500/3000 |

2618 | T6 | Φ230 | 2500/3000 |

2618 | T6 | Φ240 | 2500/3000 |

2618 | T6 | Φ250 | 2500/3000 |

2618 | T6 | Φ260 | 2500/3000 |

2618 | T6 | Φ270 | 2500/3000 |

2618 | T6 | Φ280 | 2500/3000 |

2618 | T6 | Φ290 | 2500/3000 |

2618 | T1 | Φ300 | 2500/3000 |

2618 | T1 | Φ310 | 2500/3000 |

2618 | T1 | Φ320 | 2500/3000 |

2618 | T1 | Φ330 | 2500/3000 |

Application of DTD5014 A 2618 T6 Aluminum bar

In the aerospace industry, aluminum bar DTD 5014A 2618 T6 is also the leading material for racing piston production and widely used for a variety of high-temperature service applications.

Racing engine components

Chassis components

Aerospace components

Defence applications