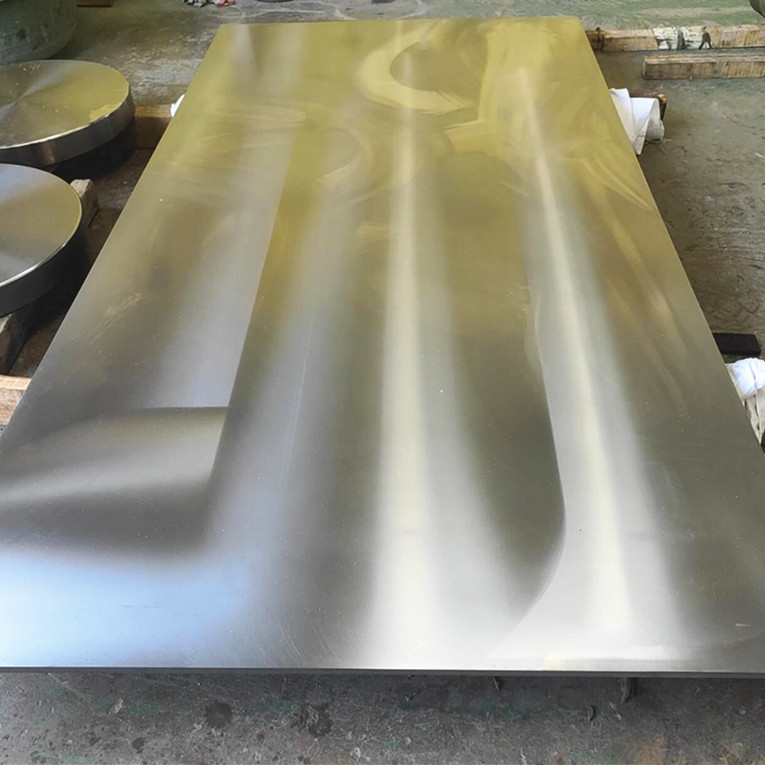

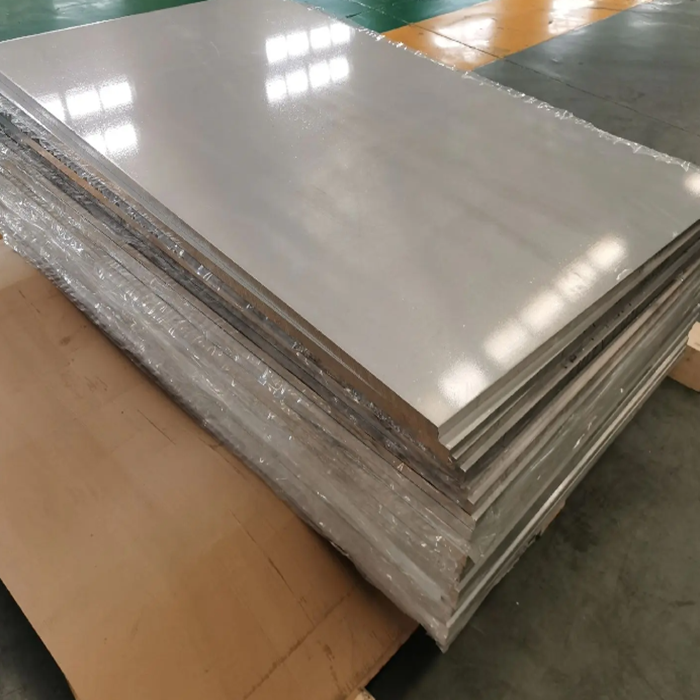

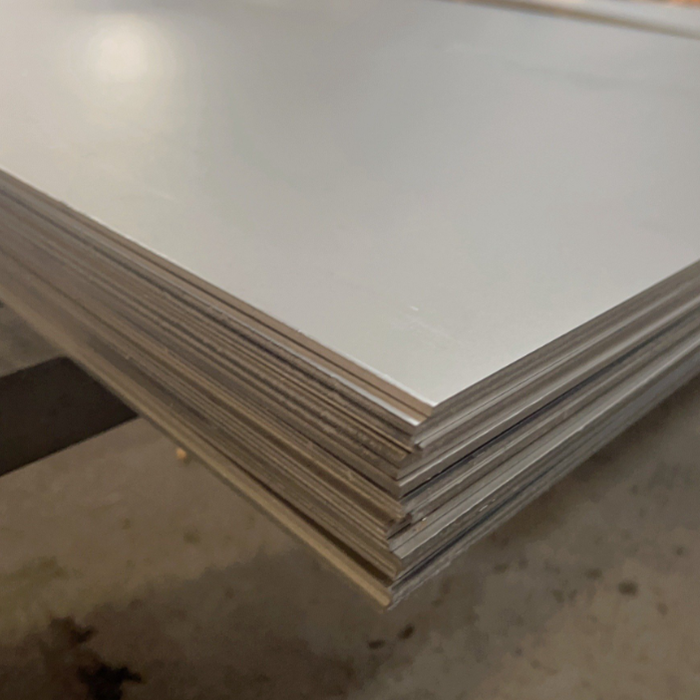

Gr1 Gr3 Gr9 Titanium Plate Hot and Cold Rolled

Titanium plates, particularly Grades 1, 3, and 9, are renowned for their unique combination of high strength, low weight, and exceptional corrosion resistance. Available in both hot-rolled and cold-rolled forms, these titanium plates cater to a wide range of industrial applications. Below is a detailed introduction to Gr1, Gr3, and Gr9 titanium plates, highlighting their properties and specific applications.

Titanium Grade 1 (Gr1) Plates

Properties:

Purity: Titanium Grade 1 is the most ductile and softest titanium alloy, with a purity of about 99.5% titanium.

Corrosion Resistance: Exceptional resistance to corrosion in a variety of environments, including seawater and industrial chemicals.

Formability: Excellent formability and weldability, making it easy to work with for various fabrication processes.

Low Strength: While Gr1 has the lowest strength among titanium grades, it is favored for its flexibility and toughness.

Applications:

Chemical Processing: Equipment and piping systems handling corrosive substances.

Marine Applications: Shipbuilding and offshore structures exposed to seawater.

Medical Industry: Surgical implants and devices due to its biocompatibility.

Desalination Plants: Components in evaporators and condensers.

Titanium Grade 3 (Gr3) Plates

Properties:

Moderate Strength: Higher strength than Gr1, but still maintains good ductility and formability.

Corrosion Resistance: Strong resistance to corrosion in oxidizing and mildly reducing environments.

Weldability: Good weldability, suitable for various joining processes.

Applications:

Aerospace Industry: Airframe components that require a balance of strength and weight savings.

Industrial Applications: Parts and equipment exposed to corrosive environments.

Heat Exchangers: Efficient and durable heat exchangers in power plants and chemical processing facilities.

Titanium Grade 9 (Gr9) Plates

Properties:

High Strength-to-Weight Ratio: Combines excellent strength with lightweight characteristics, often referred to as Ti-3Al-2.5V.

Corrosion Resistance: Superior resistance to corrosion, especially in high-stress environments.

High Formability: Good formability, making it suitable for complex shapes and structures.

Weldability: Excellent weldability, ensuring strong and reliable joints.

Applications:

Aerospace Components: Tubing, structural components, and other high-stress parts in aircraft and spacecraft.

Sports Equipment: High-performance sports gear such as bicycle frames and golf club shafts.

Automotive Industry: High-end exhaust systems and performance parts.

Medical Devices: Surgical instruments and implants requiring high strength and low weight.

Manufacturing Processes

Hot Rolled Titanium Plates:

Process: Involves rolling the titanium at high temperatures, typically above the metal’s recrystallization temperature.

Benefits: Produces plates with refined grain structures, enhancing mechanical properties and surface finish.

Applications: Suitable for applications requiring thicker plates and where surface finish is less critical.

Cold Rolled Titanium Plates:

Process: Involves rolling the titanium at room temperature, below its recrystallization temperature.

Benefits: Results in plates with a smoother surface finish, improved dimensional accuracy, and increased strength due to work hardening.

Applications: Ideal for applications needing thinner plates, superior surface finish, and tighter tolerances.