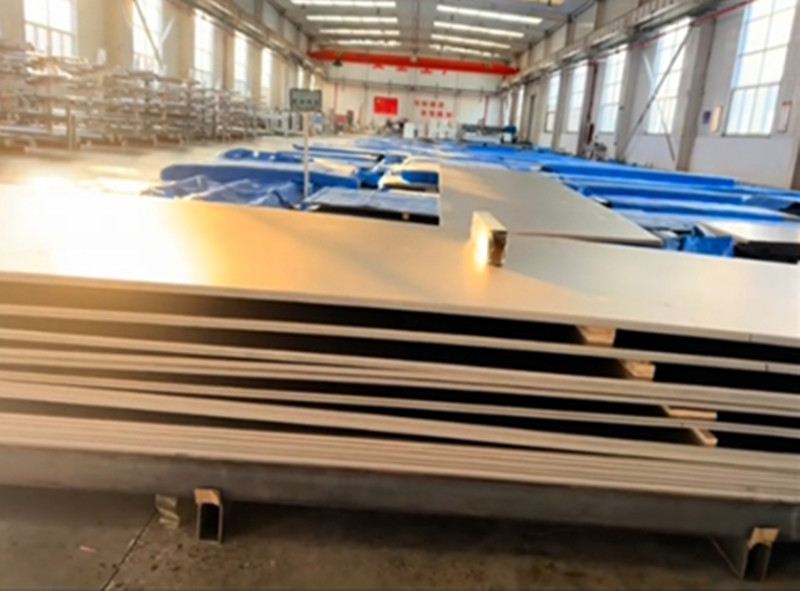

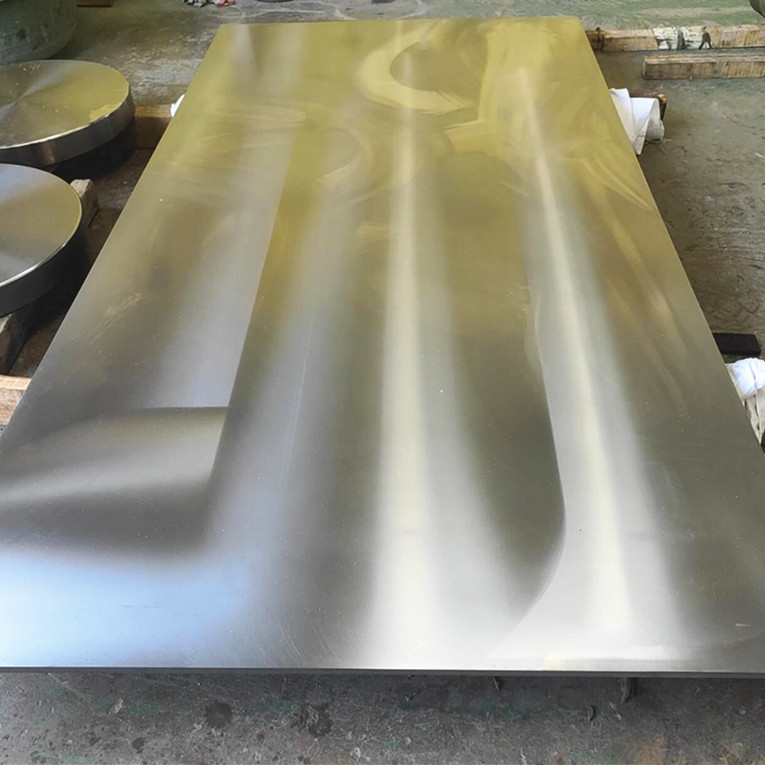

AMS 4902 Aerospace Pure Titanium TA1 Grade1 Plate Sheet

Titanium TA1 Grade 1 is the softest and most ductile of all commercially pure (CP) titanium grades. Titanium Grade 1 plates are widely used in industries such as aerospace, marine, chemical processing, medical, and renewable energy.

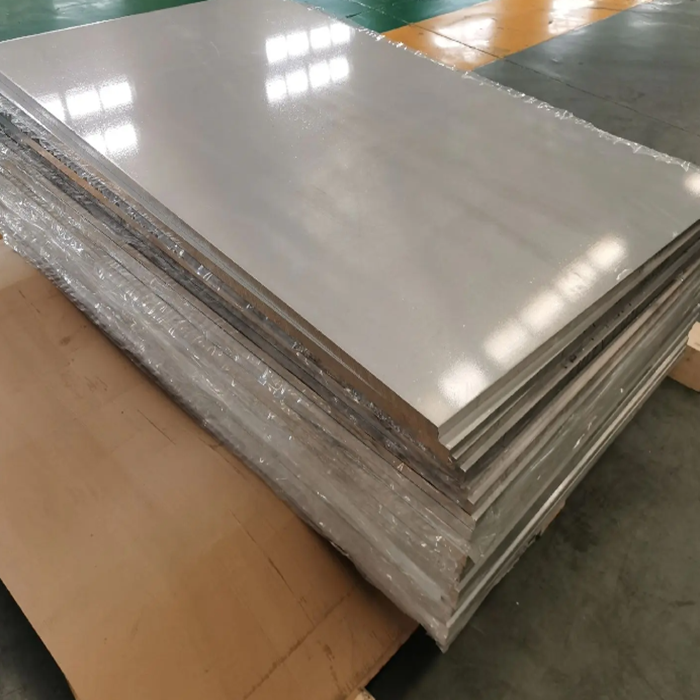

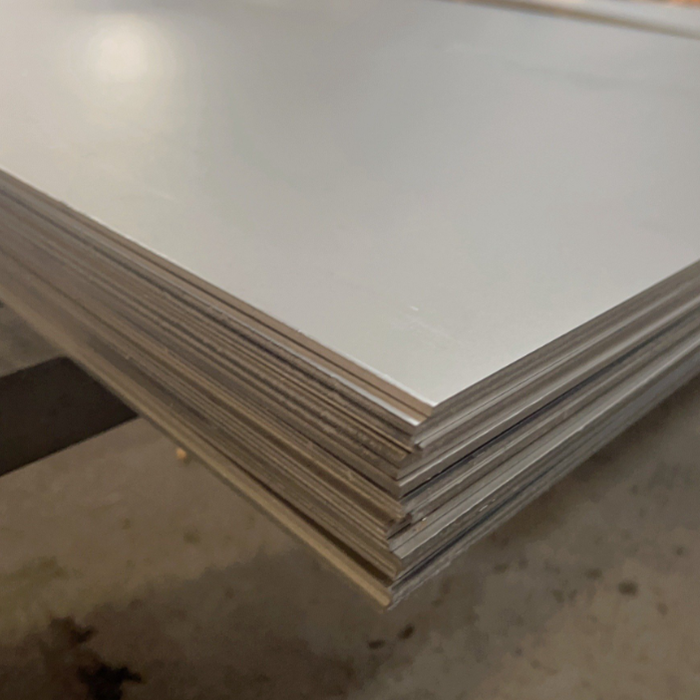

Standard Dimensions for Titanium TA1 Grade 1 Plates and Sheets

Category | Dimension Range |

Thickness | Plates: 6 mm to 100 mm or more |

Sheets: 0.5 mm to 6 mm | |

Width | 1000 mm (39.37 inches) |

1220 mm (48.03 inches) | |

1500 mm (59.05 inches) | |

2000 mm (78.74 inches) | |

Length | 2000 mm (78.74 inches) |

2440 mm (96.06 inches) | |

3000 mm (118.11 inches) | |

4000 mm (157.48 inches) |

Chemical Composition of Titanium TA1 Grade 1

Element | Maximum Content (%) |

Titanium (Ti) | ~99.5 (minimum) |

Oxygen (O) | 0.18 |

Nitrogen (N) | 0.03 |

Carbon (C) | 0.08 |

Hydrogen (H) | 0.015 |

Iron (Fe) | 0.2 |

Key Points About the Composition

1.High Titanium Content (~99.5%)

l Ensures excellent corrosion resistance, biocompatibility, and low density.

l Provides good mechanical strength relative to its weight.

2.Low Impurity Levels

l Strict limits on oxygen, nitrogen, hydrogen, and carbon to maintain ductility, toughness, and weldability.

l Excessive impurities could lead to brittleness and reduced performance.

3.Iron as a Trace Element

l Small amounts of iron (Fe) enhance the strength without significantly compromising corrosion resistance.

Standards Defining Composition

The chemical composition of Titanium TA1 Grade 1 is standardized under international specifications, including:

l ASTM B265: Standard for titanium plates, sheets, and strips.

l AMS 4902: Aerospace material specification.

l ISO 5832-2: Standards for biomedical applications.

Mechanical Properties of Titanium TA1 Grade 1

Property | Value |

Tensile Strength | 240 MPa (minimum) |

Yield Strength | 170 MPa (minimum) |

Elongation | 24% (minimum) |

Density | 4.51 g/cm³ |

Melting Point | ~1660°C |

Why Choose Titanium Grade 1 Plate?

Titanium Grade 1 plates are ideal for applications requiring:

l Superior corrosion resistance.

l High ductility for forming and fabrication.

l Lightweight material with good mechanical properties.

l Long-lasting performance in harsh environments.

Typical Applications of Titanium TA1 Grade 1 Plate

Aerospace

Manufacturing heat shields, airframes, and other lightweight, corrosion-resistant components.

Marine Engineering

Used for shipbuilding, desalination systems, and offshore structures due to its resistance to seawater corrosion.

Chemical Processing

Fabrication of heat exchangers, reaction vessels, and piping systems in industries dealing with aggressive chemicals.

Medical Field

Used in surgical implants, prosthetics, and medical equipment thanks to its biocompatibility.

Renewable Energy

Incorporated in solar panels, wind turbines, and geothermal systems due to its resistance to harsh environmental conditions.

Architecture

Used in decorative and structural components, benefiting from its corrosion resistance and unique aesthetic appearance.