TC4 Gr5 Ti6Al4V Titanium Plate Sheet Aerospace

What is TC4 Titanium?

TC4 alloy is a medium-strength α-β two-phase titanium alloy containing 6% α-stabilizing element AI and 4% β-stabilizing element V. The alloy has excellent overall properties and has gained the widest application in the aviation and aerospace industries. The alloy has a long working temperature of up to 400°C.

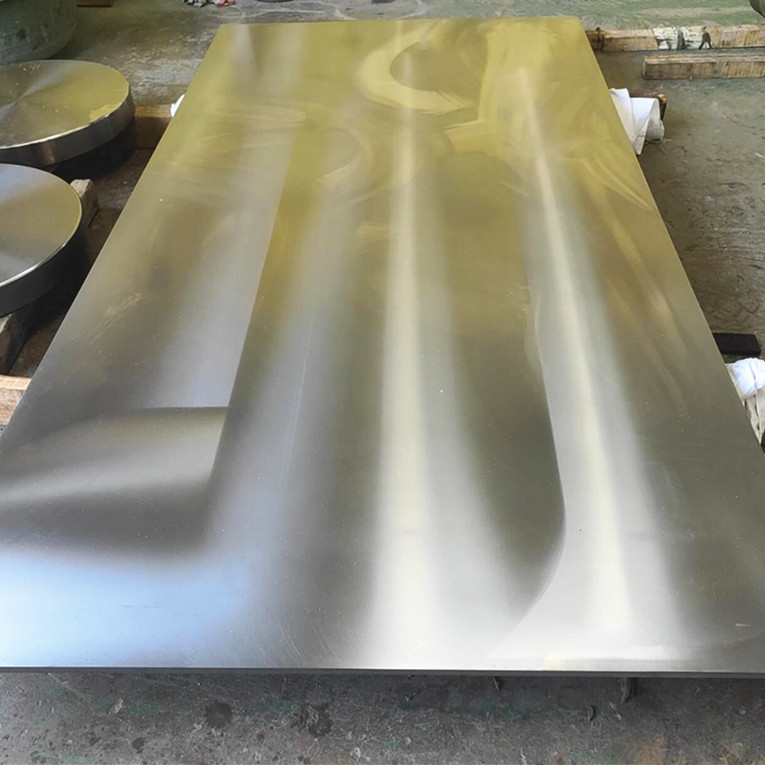

In the aerospace industry, it is mainly used in the manufacture of engine fan and compressor disks and blades, as well as important load-bearing components such as beams, joints and spacer frames in the structure of aircraft. The main semi-finished products of TC4 titanium alloy are bars, forgings, thick plates, thin plates, profiles and wires. The alloy is mainly used in the annealed condition, but can also be strengthened to some extent by solid solution aging, however, the hardened section generally does not exceed 25mm. The alloy has good process plasticity and superplasticity, and is suitable for a variety of pressure machining and forming. The alloy can also be welded and machined in various ways.

TC4 Titanium Alloy Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (σb) / MPa | ≥ 895 |

| Specified Residual Elongation Stress (σ0.2) / MPa | ≥ 825 |

| Elongation (δ) / % | ≥ 10 |

| Section Shrinkage (ψ) / % | ≥ 25 |

TC4 Titanium Alloy Chemical Composition

| Element | Content (%) |

|---|---|

| Titanium (Ti) | Balance |

| Iron (Fe) | ≤ 0.30 |

| Carbon (C) | ≤ 0.10 |

| Nitrogen (N) | ≤ 0.05 |

| Hydrogen (H) | ≤ 0.015 |

| Oxygen (O) | ≤ 0.20 |

| Aluminum (Al) | 5.5 - 6.8 |

| Vanadium (V) | 3.5 - 4.5 |

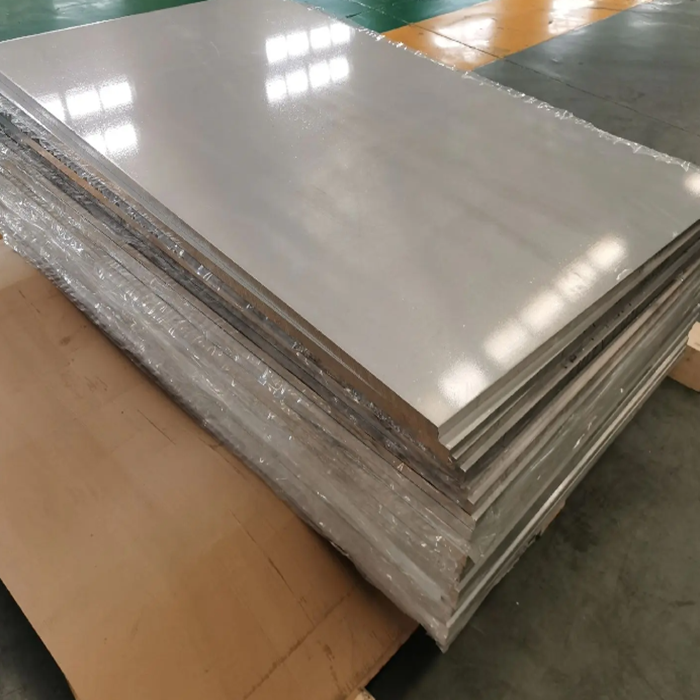

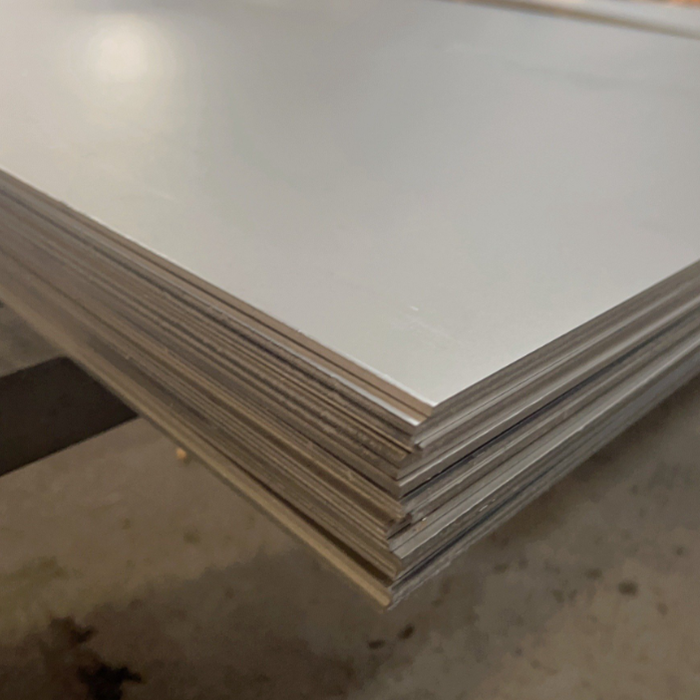

Hot rolled plate: thickness 4---100mm, standard: GB/T3621-2007

Cold rolled sheet: thickness 0.5---4mm, standard: GB/T26723-2001