5052 vs 6061 vs 3003 Aluminum: Which One Is Better for Your Project?

When choosing aluminum alloys, people often struggle to decide between 3003, 5052, and 6061. At first glance, these alloys may seem similar, but each has distinct strengths and limitations. Picking the wrong one can result in higher costs, reduced performance, or manufacturing difficulties. This article provides a practical comparison of their properties and applications to help you select the right alloy for your project.

1. 6061 vs 5052 vs 3003 aluminum Chemical Composition

| Alloy | Mg (%) | Si (%) | Mn (%) | Cu (%) | Cr (%) | Fe (%) | Others |

|---|---|---|---|---|---|---|---|

| 6061 | 0.8–1.2 | 0.4–0.8 | ≤0.15 | 0.15–0.40 | 0.04–0.35 | ≤0.7 | Balance Al |

| 5052 | 2.2–2.8 | ≤0.25 | ≤0.10 | ≤0.10 | 0.15–0.35 | ≤0.4 | Balance Al |

| 3003 | ≤0.05 | ≤0.60 | 1.0–1.5 | 0.05–0.20 | — | ≤0.7 | Balance Al |

2. 5052 vs 6061 vs 3003 aluminum Mechanical & Physical Properties

| Property | 6061 | 5052 | 3003 |

|---|---|---|---|

| Temper | T6 | H32 / H34 | H14 / H112 |

| Yield Strength (MPa) | ~275 | ~193 | ~145 |

| Ultimate Tensile Strength (MPa) | ~310 | ~228 | ~200 |

| Modulus of Elasticity (GPa) | 68.9 | 70 | 69 |

| Thermal Conductivity (W/m·K) | 167 | 138 | 160 |

| Melting Point (°C) | 582–652 | 607–650 | 643–654 |

| Electrical Resistivity (µΩ·cm) | 4.0 | 4.9 | 3.0 |

| Brinell Hardness (HB) | ~95 | ~60 | ~50 |

| Machinability | Good (~50%) | Fair (~30%) | Poor (~20%) |

| Density (g/cm³) | 2.70 | 2.68 | 2.73 |

3. 5052 aluminum vs 6061 vs 3003 Corrosion Resistance

| Alloy | Corrosion Resistance Rating | Notes |

|---|---|---|

| 6061 | Good | General corrosion resistance; slightly reduced by copper content. Suitable for outdoor and structural applications. |

| 5052 | Excellent | Excellent resistance in marine and chemical environments; ideal for ship, tank, and fuel system use. |

| 3003 | Very Good | Resists atmospheric and chemical corrosion; not suitable for prolonged seawater exposure. |

4. Al 5052 vs 6061 vs 3003 Welding Performance

| Alloy | Weldability | Typical Methods | Remarks |

|---|---|---|---|

| 6061 | Good | MIG, TIG | Weldable by all methods; post-weld heat treatment may be needed to restore strength. |

| 5052 | Excellent | MIG, TIG, Resistance Welding | Excellent weldability, low cracking tendency; common in sheet and marine fabrication. |

| 3003 | Excellent | MIG, TIG | Very good weldability and formability; used in heat exchangers and tanks. |

5. Application comparison

5052 aluminum is ideal for:

Marine parts (boat hulls, tanks, bulkheads)

Electrical enclosures and cabinets

Architectural panels and curved surfaces

Components requiring high corrosion resistance

5052 featured products: 5052 aluminum tread plate, 5052 anodized sheet coil

6061 aluminum is ideal for:

Structural frames and supports

Automotive and aerospace parts

CNC-machined components

Bicycle frames and performance applications

6061 featured products: 6061 high precision super flat plate, 6061 hexagon bar

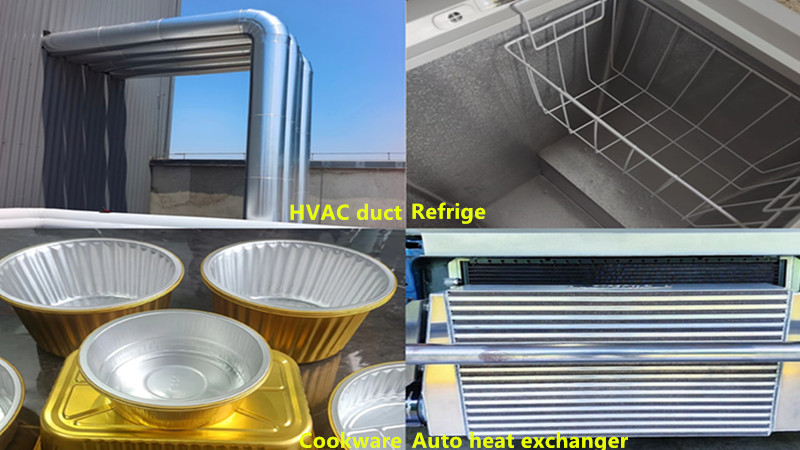

3003 Aluminum is ideal for:

Roofing sheets

Siding panels

Decorative sheets

Cookware & utensils

Chemical storage tanks

HVAC ducts & covers

Traffic signs

Insulation jacketing

3003 featured products: 3003 stucco embossed sheet, 3003 aluminum tread plate

4. Frequently asked questions (FAQ)

Can 5052 and 6061 be welded together?

Technically yes, but it’s not recommended. The different compositions can lead to weak joints, cracking, or galvanic corrosion. If necessary, use filler alloy 5356 and consult a welding specialist.

What is the difference between 5052 and 6061 aluminum?

5052 offers superior corrosion resistance and forming ability. 6061 delivers greater strength and machining performance. Your choice depends on your specific project needs.

Which one is better for anodizing?

5052 usually delivers a brighter, more uniform anodized finish with fewer defects.

Is 6061 aluminum stronger than 5052?

Yes. 6061-T6 is stronger than 5052-H32, both in tensile and yield strength.

Which is better for marine use?

5052 is the preferred material due to its excellent saltwater corrosion resistance.

Which is more corrosion-resistant, 5052 or 3003 aluminum?

If you plan to use aluminum outdoors, near the sea, or in a humid environment, 5052 will last longer. That's because it contains magnesium, which gives it stronger resistance to seawater and salt spray. 3003 can also resist rust, but it's more suitable for regular indoor use, like roofing sheets or decorative panels. In coastal areas, 5052 is the safer choice for long-term durability.

Which is stronger, 5052 or 3003 aluminum?

When it comes to strength, 5052 clearly has the advantage. It is harder and more resistant to pressure or impact, making it ideal for car bodies, truck boxes, or boat structures. 3003, on the other hand, is softer and better for things like cookware or roofing sheets where extreme strength is not required. Simply put: choose 5052 for durability, and 3003 for lighter everyday needs.

Can you bend 5052 or 3003 aluminum?

3003 aluminum is more flexible and easier to form. It’s great for embossing, punching, or stretching, which is why you often see it used for aluminum pans, tread plates, or roofing panels. 5052 can also be welded and bent, but its higher hardness makes it less convenient for complex shaping. In short, 3003 is better for products that need detailed designs, while 5052 suits parts that must be stronger.

5052 vs 3003 aluminum cost

In general, 5052 is slightly more expensive than 3003. For everyday household use, such as kitchenware or indoor decoration, 3003 is already affordable and practical. But if you need aluminum for harsher conditions—outdoor structures, vehicles, or coastal equipment—spending a bit more on 5052 is worth it, since its superior corrosion resistance and strength mean a longer lifespan.