Aluminum Temper Meaning and Chart

When selecting aluminum materials, you often encounter designations like T6, O, or H14.

These designations are known as Tempers, which describe the mechanical and physical condition of the material after processing or heat treatment.

Understanding tempers helps you choose the right material for your application and avoid performance failures during use.

What Is Aluminum Temper?

Aluminum Temper refers to the condition of aluminum alloys after they have been strengthened through heat treatment, cold working, or a combination of processes.

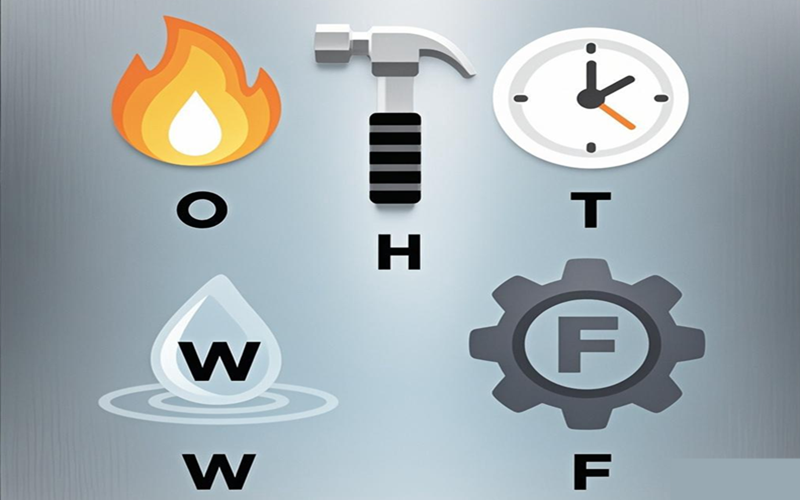

Tempers are usually represented by a letter (F, O, H, W, T) followed by one or more numbers. For example:

T6: Solution heat-treated and artificially aged

H14: Strain hardened to half hard

O: Fully annealed for maximum softness

Each temper defines specific mechanical properties and is suitable for different applications.

Full Aluminum Temper Chart

| Temper | Category | Description |

|---|---|---|

| F | As-Fabricated | No special control over thermal or strain-hardening conditions |

| O | Annealed | Fully annealed to obtain maximum softness and ductility |

| H1X | Strain Hardened Only | Cold worked to increase strength without thermal treatment |

| H11 | Slightly strain hardened (about 10%) | |

| H12 | Strain hardened to about 25% strength | |

| H14 | Strain hardened to about 50% strength | |

| H16 | Strain hardened to about 75% strength | |

| H18 | Full hard (maximum strain hardening) | |

| H2X | Strain Hardened and Partially Annealed | |

| H22 | 25% strain hardened and partially annealed | |

| H24 | 50% strain hardened and partially annealed | |

| H26 | 75% strain hardened and partially annealed | |

| H3X | Strain Hardened and Stabilized | For magnesium-containing alloys |

| H32 | 25% strain hardened and stabilized | |

| H34 | 50% strain hardened and stabilized | |

| H36 | 75% strain hardened and stabilized | |

| W | Solution Heat-Treated | Solution treated, aging naturally over time (unstable temper) |

| T1 | Cooled from elevated-temperature shaping process and artificially aged | |

| T2 | Cooled from elevated-temperature shaping process, then cold worked | |

| T3 | Solution heat-treated, cold worked, and naturally aged | 2024-T3 |

| T351 | Solution heat-treated, cold worked, stress-relieved, and naturally aged | |

| T4 | Solution heat-treated and naturally aged to a substantially stable condition | |

| T42 | Annealed, then solution treated and naturally aged | |

| T5 | Cooled from elevated-temperature shaping process and artificially aged | |

| T51 | Cooled from elevated-temperature shaping process, stress-relieved, and artificially aged | |

| T52 | Special cooling from elevated temperature, then artificially aged | |

| T6 | Solution heat-treated and artificially aged for maximum strength | 7075-T6、6061-T6 |

| T651 | Solution heat-treated, stress-relieved by stretching, and artificially aged | |

| T7 | Solution heat-treated and overaged for stability and corrosion resistance | |

| T73 | Special overaging for improved corrosion resistance | 7075-T73 |

| T7351 | Overaged and stress-relieved | |

| T76 | Moderately overaged | |

| T79 | Severely overaged for maximum corrosion resistance | |

| TX51 | Stress-relieved (stretching), such as T351, T651 series |

Common Applications of Different Aluminum Tempers

| Application Field | Recommended Tempers | Why |

|---|---|---|

| Aerospace structural components | T6, T651, T73, T7351 | High strength and corrosion resistance |

| Automotive parts | T4, T6 | Good formability and weldability |

| Molds and tooling | T6, T651 | High strength, dimensional stability |

| Building facades and panels | H14, H24, O | Good formability, attractive surfaces |

| Marine and offshore applications | H32, H116 | Excellent corrosion resistance |

| Pressure vessels and hydraulic parts | O, H112 | High ductility, pressure resistance |

Conclusion

Understanding different Aluminum Tempers enables you to select the right material for maximum performance, durability, and manufacturing success.

If you are looking for a reliable aluminum material supplier, Shenzhen Chinalco Metal offers a wide range of tempers such as T6, T651, O, and H14, available in stock or customized. Feel free to contact us for more information!