Titanium vs Aluminum vs Steel: Weight, Strength, and Best Applications

Selecting the right material is a hard thing, because the metals with different material properties but similar applications sometimes. Titanium, aluminum and steel are all widely used, how to pick the right and economical material for your production, let's analyze these three metals today, from the weight, density, strength and applications etc. Hope this artical useful for you.

Titanium vs aluminum performance comparison

| Comparison Dimension | Titanium (Ti) | Aluminum (Al) |

|---|---|---|

| Composition | Mainly Ti, with trace elements such as O, Ni, N, Fe, C, H | Mainly Al, often alloyed with Zr, Zn, Cr, Si, Mg, Ti, Mn, Fe, Cu |

| Density | 4500 kg/m³, about 2/3 heavier than aluminum but lighter than steel | 2712 kg/m³, significantly lighter, strong advantage in weight reduction |

| Strength | Tensile strength 230–1400 MPa, yield strength 170–480 MPa, excellent in high-strength alloys | Tensile strength 90 MPa (pure Al), up to 690 MPa for heat-treated alloys; yield strength 200–600 MPa |

| Shear Strength | ~40–45 MPa | 85–435 MPa, some aluminum alloys outperform titanium |

| Hardness | Generally harder, better wear resistance | Some high-strength alloys (e.g., 7075-T6) can match or exceed certain titanium alloys |

| Thermal Conductivity | 17 W/m·K, better for thermal insulation | 210 W/m·K, excellent heat transfer, widely used in radiators and heat exchangers |

| Electrical Conductivity | 3.1% IACS (relative to copper), poor conductor | 64% IACS, widely used for wires, cables, and conductors |

| Melting Point | 1650–1670 °C, high-temperature resistant metal | 660 °C, low melting point, easy casting, but poor at high temperatures |

| Corrosion Resistance | Excellent, resistant to acids, alkalis, seawater, chlorides, long service life | Relies on oxide film, good in normal environments but vulnerable in saltwater or acidic/alkaline conditions |

| Machinability | Difficult to machine, requires high cutting force, tools wear quickly, higher cost | Easy to machine, lower cutting resistance, longer tool life, lower cost |

| Formability | Relatively poor, low ductility, prone to springback during forming | Excellent, suitable for stamping, drawing, forging, and casting |

| Cost | High raw material and processing cost | Low cost, suitable for mass production |

| Typical Applications | Aerospace, deep-sea equipment, medical implants, high-temperature components | Automotive, construction, electronics, packaging, heat exchangers, electrical conductors |

Aluminum vs Steel Performance Comparison

| Comparison Dimension | Aluminum (Al) | Steel (Fe-based) |

|---|---|---|

| Composition | Mainly Al, often alloyed with Mg, Si, Cu, Zn, Mn, Ti, Cr | Mainly Fe, alloyed with C, Mn, Cr, Ni, Mo, etc. |

| Density | 2712 kg/m³, lightweight, ideal for weight reduction | 7850 kg/m³, much heavier, less suitable for lightweight applications |

| Strength | Tensile strength 90–690 MPa (heat-treated alloys), yield 200–600 MPa | Tensile strength 400–1200 MPa (depending on grade), yield 250–1000 MPa, generally stronger than aluminum |

| Shear Strength | 85–435 MPa, varies with alloy | 200–700 MPa, generally higher than aluminum |

| Hardness | Moderate; some high-strength alloys (e.g., 7075-T6) can match steel | Generally higher, good wear resistance |

| Thermal Conductivity | 210 W/m·K, excellent heat transfer | 40–60 W/m·K, much lower than aluminum |

| Electrical Conductivity | ~64% IACS, good conductor | Very low, poor conductor |

| Melting Point | 660 °C, low, easy casting | 1370–1530 °C, high, suitable for high-temperature applications |

| Corrosion Resistance | Forms protective oxide layer, generally good | Susceptible to rust; stainless steel grades are corrosion-resistant |

| Machinability | Excellent, low cutting resistance, easy forming | Good to moderate; some high-strength steels are harder to machine |

| Formability | Excellent, suitable for stamping, drawing, forging, casting | Moderate; low-carbon steels are formable, high-carbon steels less so |

| Cost | Low, suitable for large-scale production | Moderate to high, depending on grade |

| Typical Applications | Automotive panels, aerospace components, packaging, heat exchangers, electronics | Construction, machinery, automotive frames, pipelines, tools |

Aluminum vs titanium vs stainless steel weight quick comparison:

Aluminum: ~2.7 g/cm³, very light, ideal for weight-sensitive applications.

Titanium: ~4.5 g/cm³, about 1.7 times heavier than aluminum but much lighter than steel.

Stainless Steel: ~7.9–8.0 g/cm³, the heaviest of the three, almost 3 times heavier than aluminum.

In short: Aluminum < Titanium < Stainless Steel in weight.

And want to calculate the exact weight of different forms of metal, we have the metal weight calculation

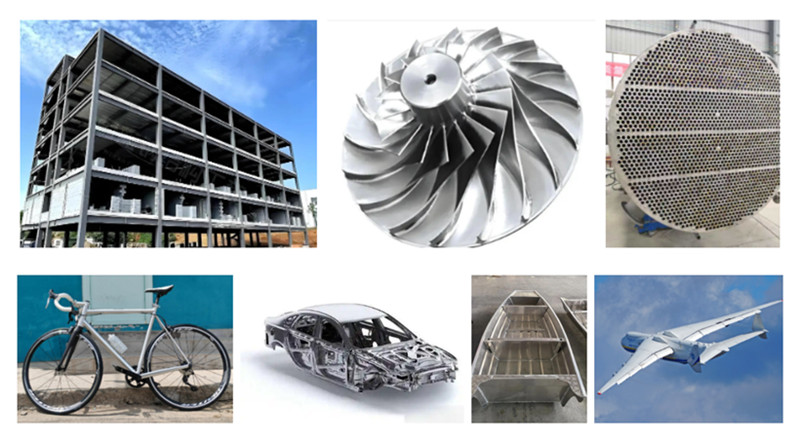

Aluminum vs titanium vs steel common uses

1,Aluminum is used for applications where light weight, corrosion resistance, and good machinability are important. Aluminum is commonly used for aerospace structures, automotive body panels, packaging such as cans and foil, heat exchangers, electronics housings, and building facades.

2,Titanium is used for applications requiring high strength, low weight, excellent corrosion resistance, or biocompatibility. Titanium is commonly used for aircraft and spacecraft components, medical implants such as joint replacements and dental implants, deep-sea equipment, and high-performance sporting goods.

3,Steel is used for applications that demand high strength, durability, and cost-effectiveness. Steel is commonly used for construction elements such as beams and rebar, automotive frames, pipelines, machinery, tools, kitchenware, chemical processing equipment, and medical instruments (stainless steel).

Popular Aluminum Alloys

6061 Aluminum Alloy – Offers an excellent balance of strength, corrosion resistance, and weldability, widely used in transportation and structural applications.

7075 Aluminum Alloy – A high-strength alloy known for superior fatigue resistance, ideal for aerospace and high-performance equipment.

5052 Aluminum Alloy – Noted for outstanding corrosion resistance and formability, commonly used in marine and sheet metal applications.

Popular Titanium Alloys

Ti-6Al-4V (Grade 5) – The most widely used titanium alloy, combining high strength, low weight, and excellent corrosion resistance.

Grade 2 (Commercially Pure Titanium) – Offers good ductility and excellent corrosion resistance, ideal for chemical and marine industries.

Ti-3Al-2.5V (Grade 9) – Provides a balance of strength, formability, and weldability, suitable for aerospace tubing and sports equipment.

FAQ

1. Is titanium lighter than aluminum?

Many assume titanium is lighter than aluminum, but the reality is more nuanced. Density determines a material’s weight, and here’s how these metals compare:

Aluminum Alloy (6061): Density ~2.7 g/cm³

Titanium Alloy (TC4/Grade 5): Density ~4.5 g/cm³

Titanium is about 67% heavier than aluminum by volume. However, weight efficiency is not determined by density alone. Titanium has a much higher specific strength (strength-to-weight ratio), meaning it can be used in thinner sections while maintaining the same structural integrity as aluminum. This makes it an excellent choice in applications where strength and weight efficiency are both critical.

2. Is titanium stronger than aluminum?

Yes, titanium is stronger than aluminum, but the choice between the two depends on the application. Titanium has a much higher tensile strength, ranging from 230 MPa for pure titanium up to 1400 MPa for advanced alloys, while even the strongest aluminum alloys (like 7075-T6) reach around 690 MPa. This means titanium can handle greater loads and stresses without deforming, making it ideal for aerospace, medical implants, and other demanding uses. However, aluminum is lighter, cheaper, and easier to machine, so in industries where cost, weight savings, and large-scale production matter more than maximum strength, aluminum is often preferred.

3. Is steel stronger than aluminum

Yes, steel is generally stronger than aluminum, especially in terms of tensile and yield strength. Most structural steels can easily exceed 400–1000 MPa in strength, while even the strongest aluminum alloys, such as 7075-T6, top out around 600–700 MPa. This means steel can withstand heavier loads and higher stress without deforming. However, aluminum is about one-third the weight of steel and offers excellent corrosion resistance and machinability, so while steel is stronger, aluminum is often chosen when light weight and easier processing are more important than maximum strength.

4. Does titanium vs aluminum conduct heat quickly?

Aluminum conducts heat much faster than titanium.

Aluminum has a thermal conductivity of about 205 W/m·K, while titanium is only around 17 W/m·K—more than a 10× difference.

So aluminum dissipates heat quickly, and titanium does not.

5. How to tell aluminum vs stainless steel?

Aluminum is much lighter and non-magnetic; stainless steel is heavier and sometimes slightly magnetic.

Aluminum has a density of 2.7 g/cm³, while stainless steel is around 7.8 g/cm³, nearly 3× heavier.

Most stainless steels show at least a slight magnetic response, while aluminum is fully non-magnetic.

6. How to tell titanium vs aluminum?

Titanium is darker, stronger, and heavier than aluminum.

Aluminum's density is 2.7 g/cm³, whereas titanium is 4.5 g/cm³—about 67% heavier.

Titanium has a darker gray appearance, while aluminum looks brighter and more silver-white.

7. How to tell titanium vs stainless steel?

Titanium is lighter and darker; stainless steel is shinier and almost twice as heavy.

Titanium's density is 4.5 g/cm³, compared to 7.8 g/cm³ for stainless steel—stainless is roughly 1.7× heavier.

Titanium has a matte gray tone, while stainless steel is more reflective and mirror-like.

8. How hard is titanium vs steel?

Steel is usually harder, but titanium offers a better strength-to-weight ratio.

Common structural steels typically fall around 150–200 HB, and high-strength steels can exceed 300 HB.

Most titanium grades range from 100–200 HB, but their strength relative to weight is significantly higher than steel.

9. How heavy is titanium vs steel?

Titanium is about 40–45% lighter than steel.

Titanium's density is 4.5 g/cm³, while steel averages 7.8 g/cm³, making titanium roughly 42% lighter.

This is why titanium is favored for weight-critical applications.

10. Is titanium stronger than steel?

Not always—steel can be stronger, but titanium provides high strength at a much lower weight.

A common titanium alloy like Ti-6Al-4V offers tensile strength around 900 MPa, comparable to many high-strength steels but far lighter.

Titanium's advantage is not absolute strength, but strength with significantly reduced weight and excellent corrosion resistance.